API Tech Delivers Restaurant-Quality Pizza 24/7

Using SOLIDWORKS and 3DEXPERIENCE, API Tech scales Smart Pizza vending worldwide while ensuring quality, consistency, and rapid market deployment.

Challenge

Expand the market globally for new and innovative vending machines with integrate cold storage, a baking module, and automated delivery so customers can enjoy hot, fresh products around the clock.

Solution

Scaling a small team into a multinational manufacturer required adding digital tools essential to keeping pace with their growth. They added the 3DEXPERIENCE platform to manage their need for efficient bill of materials (BOM) management.

Results

• Modify and validate designs quickly to meet market requirements

• Ensure manufacturing consistency and quality control across multiple production sites

• Manage mechanical, electrical, simulation, and automation data within a single platform

• Share and update design data securely across geographically distributed teams

API Tech began in France in 2004 with expertise in industrial automation. After joining the Mentor group in 2016, its focus shifted toward food tech, a move that would fuel explosive growth. “Since 2016, we’ve specialized in food tech automation, mainly with our [Smart Pizza] pizza dispensers, but also baguette and locker dispensers,” says API Tech Deputy Director Loïc Michaux.

These aren’t your average vending machines. Each unit integrates cold storage, a baking module, and automated delivery so customers can enjoy hot, fresh products around the clock. Order-to-delivery time for a Smart Pizza is just under three minutes. Michaux notes that the vending machines enable businesses to extend their operating hours and to set up locations where they wouldn’t normally open a store.

Growth Fueled by Innovation

In 2016 API Tech employed just five people. In 2025, the number employed is around 700, with annual sales exceeding $200 million. The rapid growth has been driven not only by product demand but also by the company’s commitment to mastering every part of the manufacturing process.

“We’ve added new job roles each year to cover the entire manufacturing process—especially in the design office—so we can keep developing new dispensers and expanding our product range,” explains Michaux. “Our objectives are to position ourselves as a food tech leader in France, but of course also abroad, in the United States and in all [pizza-loving] countries.”

Related Resources

Firstly, [the platform] provides digital continuity between SOLIDWORKS designs, BOM data, and simulation data—into a seamless process. 3DEXPERIENCE also allows us to access data at any time, while being certain that the data we’re accessing is the latest available.

Expanding to the World’s Largest Pizza Market

That ambition has already taken API Tech across Europe and into the United States. In 2019 the company opened an office in New York to serve what Michaux calls “the largest pizza and vending market in the world.” According to API Tech’s U.S. Business Development Manager, Detlev Goedbloed, Smart Pizza offers business operators a way to diversify, reach new customers, and generate reliable recurring revenue through both pizza sales and accessories such as branded pizza boxes and food-transport containers.

Smart Pizza units can hold up to 96 par-baked pizzas, bake two at a time in authentic hearth ovens, and produce a restaurant-quality product in three minutes. The system can handle 200 different pizza recipes, giving operators tremendous flexibility. Locations range from gas stations and hospitals to office complexes and schools, anywhere with high foot traffic and need for 24/7 food service.

The Digital Continuity Backbone

Scaling from a small team to a multinational manufacturer involved major engineering and production challenges. For Paul-Emmanuel Magnin, who oversees industrialization at API Tech, digital tools were essential to keeping pace. “Our growth has led us to open several sites in France and internationally. Each of these sites produces the same units, but with different products.” Magnin emphasizes the critical need for efficient bill of materials (BOM) management.

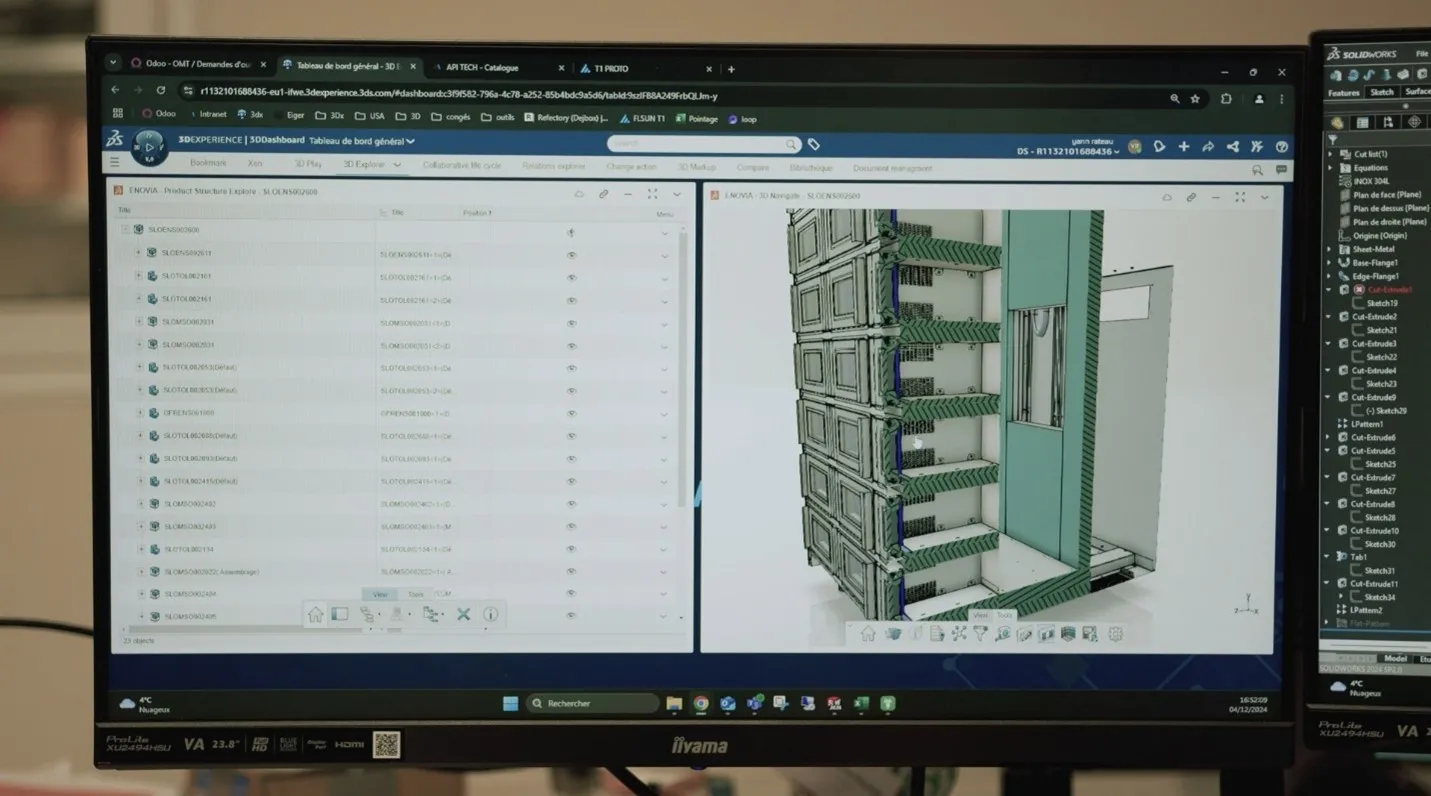

Already an established SOLIDWORKS® customer, API Tech’s choice of the 3DEXPERIENCE® platform was strategic. “Firstly, it provides digital continuity between SOLIDWORKS designs, BOM data, and simulation data—into a seamless process,” notes Magnin. “3DEXPERIENCE also allows us to access data at any time, while being certain that the data we’re accessing is the latest available.”

With cloud-based 3DEXPERIENCE, API Tech can manage both the engineering BOM (EBOM) and the manufacturing BOM (MBOM) in one environment and plans to integrate all electrical diagrams, automation programs, and related documentation as well. “Managing [all that data] with the 3DEXPERIENCE platform is a real time-saver,” Magnin enthuses.

Designing for a Competitive Edge

SOLIDWORKS plays a critical role in API Tech’s design workflow, enabling engineers to create highly detailed models of mechanical assemblies, electrical layouts, and enclosure designs. The integration with 3DEXPERIENCE ensures that any design update automatically propagates to the right teams and locations, which minimizes errors and keeps production on schedule.

This integration is especially important when adapting Smart Pizza designs for different countries and climates. A unit destined for outdoor use in Norway must meet very different thermal and environmental requirements than one placed in a New York office building. Digital simulation allows engineers to validate designs virtually before building them, reducing prototyping costs and speeding time to market.

Supporting Future Growth

For API Tech, combining SOLIDWORKS with the 3DEXPERIENCE platform creates a unified engineering and data management environment. This setup enables the company to:

• Modify and validate designs quickly to meet varying market requirements and regulatory standards

• Ensure manufacturing consistency and quality control across multiple production sites

• Manage mechanical, electrical, simulation, and automation data within a single, integrated BOM structure

• Share and update design data securely across geographically distributed teams

This integrated approach supports API Tech’s ability to produce and maintain complex food dispensing systems at scale. By centralizing all the data, the company reduces errors, shortens lead times, and keeps pace with the operational demands of its global manufacturing footprint.

Products

- SOLIDWORKS Standard

- SOLIDWORKS Simulation

- 3DEXPERIENCE Platform

Learn More About SOLIDWORKS and 3DEXPERIENCE Work

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.