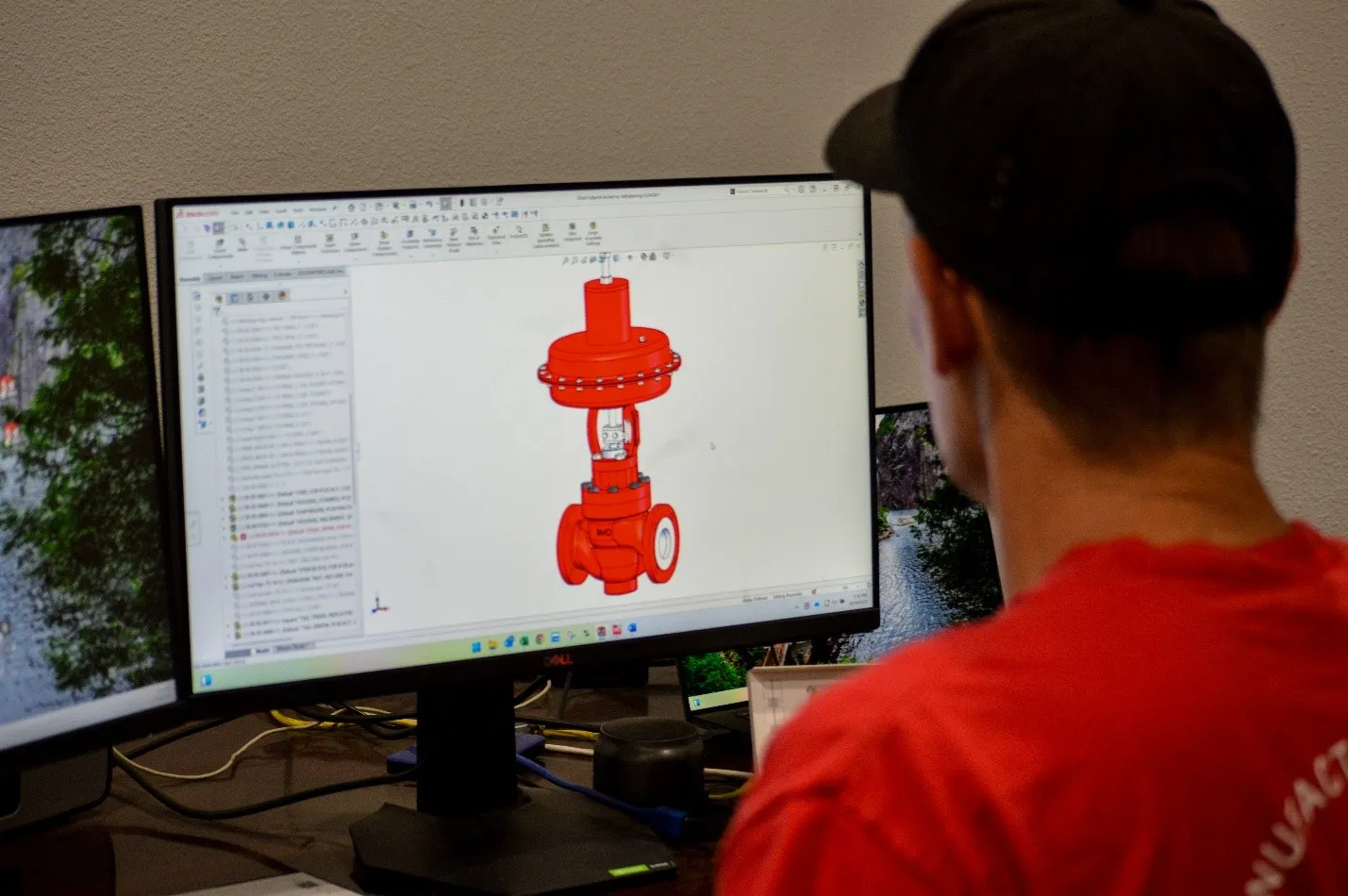

Beaumont Manufacturing Leverages SOLIDWORKS for 3D Design and Simulation

Valves and controls manufacturer depends on SOLIDWORKS and Flow Simulation to improve valve performance, minimize errors, and design faster with fewer iterations.

Challenge

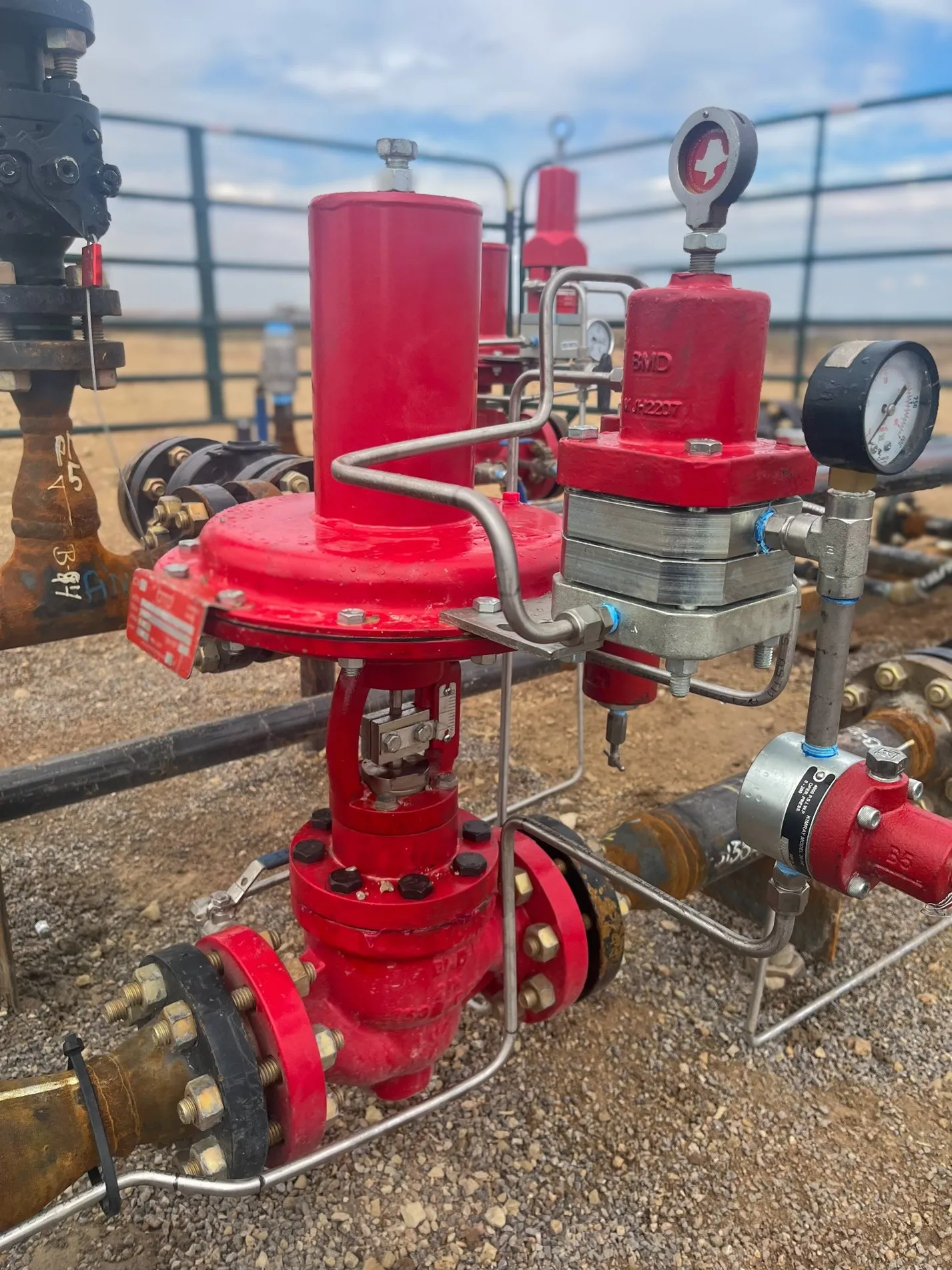

Build the highest performing valves, regulators, and controls for the oil and gas industry, engineered to handle full workloads, reduce emissions, and eliminate leaks.

Solution

Using SOLIDWORKS® Design and Flow Simulation tools to identify and design ways to enable fast, precise solutions in a lean engineering environment, allowing them to anticipate production challenges before they hit the shop floor.

Results

- Easily evaluate how fluids will move through designs virtually.

- Reduced time and number of physical prototypes

- Simulate real-world performance before updating the prototype

- Calculate the efficiency of the product within CAD

Beaumont Manufacturing and Distribution (BMD) builds high-performance valves, regulators, and controls for the oil and gas industry. BMD’s equipment is engineered to handle full workloads, reduce emissions, and eliminate leaks. SOLIDWORKS is vital to the company’s product development because it enables fast, precise design work in a lean engineering environment.

Engineering Manager Gordon Richards has been with BMD from day one; he was the firm’s first hire when it launched in 2016. Richards started out drafting designs before the business moved into full-scale manufacturing. His decision to use SOLIDWORKS from day one came naturally. “I have always used SOLIDWORKS. I had used it in previous jobs and was already very familiar with it,” he recalls. “It was kind of the obvious choice just based on experience and the ease of use.”

Engineering Without Bottlenecks

At a lean, fast-moving company like BMD, Richards’ role stretches far beyond the confines of a typical engineering manager. In a single day he might shift from designing on a computer to troubleshooting on the shop floor to working with the quality control team. “We are a small company, so I wear lots of hats,” he admits. That hands-on role shapes his approach to product development: creating models that anticipate production challenges before they hit the shop floor.

Related Resources

I use a lot of features in SOLIDWORKS, like mouse gestures,” Richards notes. “Ease of use is one of the main reasons I like SOLIDWORKS. It's very intuitive and user-friendly.

“For our products, we'll identify something in the industry that we want to make better. And then we'll start designing from there,” Richards says. He begins by creating a detailed assembly model to verify that all the parts will optimally fit together, which he then automatically verifies with SOLIDWORKS Interference Detection.

Once Richards is confident in the fit, he uses that same assembly model to run flow analyses with SOLIDWORKS Flow Simulation, which enables him to evaluate how fluids will move through the design before anything is built. This integrated approach saves time and reduces the number of design and physical prototype iterations. Instead of pushing incomplete designs downstream and waiting for problems to surface, Richards solves them early with 3D modeling and simulation analysis in SOLIDWORKS.

Tools that Fit the Way Engineers Work

Flexible modeling tools are essential to BMD’s success in designing complex challenging products. “A lot of our parts are asymmetrical, so I use the SOLIDWORKS Revolve feature all the time,” Richards notes. From these models, he can quickly create engineering drawings, generate bills of materials, and build full assembly models to verify fit and function.

Leveraging the intuitive interface in SOLIDWORKS speeds up his work even further. “I use a lot of features in SOLIDWORKS, like mouse gestures,” Richards notes. “Ease of use is one of the main reasons I like SOLIDWORKS. It's very intuitive and user-friendly.”

That user experience is more than just a convenience; it’s a competitive advantage. Richards briefly tried a competing CAD platform and found it cumbersome. “I had a little brush with Creo (a competitor to SOLIDWORKS). It's a lot more difficult to use. It seems like you had to take 10 clicks to do something that SOLIDWORKS would do in one click,” he recalls.

Built to Last

BMD’s reputation rests on ruggedness. The company’s valves and controllers must provide consistent, leak-free shut-off while offering advanced automation and durable performance in harsh environments. SOLIDWORKS helps Richards design with that level of dependability while balancing intricate internal geometries with robust housings and tight tolerances.

In an industry where downtime is costly and leaks can be catastrophic, getting the design right the first time is crucial. By leveraging SOLIDWORKS modeling, assembly, and analysis tools, Richards ensures that BMD products meet the highest standards while keeping development cycles lean enough to enable their small team to compete with bigger companies.

Products

- SOLIDWORKS 3D CAD

- SOLIDWORKS Simulation Premium

- SOLIDWORKS Flow Simulation

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.