Best Tugs Takes the Find-a-Need-and-Fill-It Mentality to the Next Level

BestTugs brings hybrid vehicle tech to aviation using SOLIDWORKS to model, test, and perfect every tug component before it hit the tarmac.

Challenge

To develop revolutionary new electric airplane tugs to replace existing designs that were heavy, difficult to maneuver, and prone to fail.

Solution

Implement SOLIDWORKS® design tools to manufacture an all-electric airplane tug designed from scratch to replace clunky levers with adaptive controls, and build a product reliable enough to work in snow, strong enough to handle turbine aircraft, and smooth enough that even a first-time user could operate it safely.

Results

- Design a new product from concept to production quickly

- Simplify the design to fewer parts for fewer mechanical errors

- Streamline the design from concept to final production model

- Manage every part within SOLIDWORKS

Mike and Mark Patey had been building and flying aircraft for years when they founded Best Aviation Products in 2016 from what started as a family project. Moving aircraft in and out of hangars with traditional gas-powered aircraft tugs was always a dicey proposition, even though specialized tugs were essential for ground-handling aircraft. “We were moving million-dollar airplanes around with what we affectionately called farm equipment,” quips Mark Patey.

Mark’s family had encountered the consequences of poor tug design firsthand. Once while his wife moved their Cirrus aircraft with a traditional tug, it experienced nose gear shimmy, or damage caused by the tug applying too much torque too abruptly. Not long after that, the family’s brand-new Meridian aircraft also suffered costly damage from overstressing the nose gear while towing.

It was especially frustrating for Mark because he and his twin brother Mike were both engineers who designed hybrid vehicle systems for their company Prodigy Engineering. After they sold their company and had time on their hands, the twins launched Best Tugs to redesign the aircraft tug. The core idea was simple: Apply proven smart motor technology from transportation into aviation ground support equipment.

The Power of Thoughtful Design

At Best Tugs, innovation doesn't mean tweaking what already exists. It means stepping back, rethinking the entire system, and daring to build something better from the ground up. That mindset transformed Best Tugs from a family project into one of the most respected names in aviation ground support.

Related Resources

As a CEO, I look at it as time and money…When you can put something in a model and see that it's going to work or not going to work, you save so much time.

To Team Patey, reimaging aircraft towing included designing electric (instead of gas-powered) tugs that ramp torque based on aircraft weight and condition; replacing clunky levers with adaptive controls; and building a product reliable enough to work in snow, strong enough to handle turbine aircraft, and smooth enough that even a first-time user could operate it safely.

Best Tugs did not have a build-and-sell-as-many-as-you-can mindset. Instead, the Pateys focused on quality and control. The goal was to apply the right tech and engineer a product that filled a glaring need. “We built a premium product,” admits Mark. “It was a bit more expensive.” While Mark and Mike did not expect to sell many of their high-quality aircraft tugs; they were happily surprised when they realized how greatly underestimated the potential market.

A Safety System on Wheels

From the beginning, Best Tugs made the strategic decision to ditch the traditional gas motor. “If we use electric motors and we could ramp them up and ramp them down a little bit slower, we [could] save a lot of stress on the nose wheel,” notes Ranch Pratt, Best Tugs CEO. By switching to electric motors with smoother acceleration and deceleration, the engineering team dramatically reduced nose wheel stress and improved traction.

In 2021 Best Tugs launched the Sierra tug line, their boldest move into the commercial aviation sector. With towing capacities reaching 99,000 pounds, the Sierra marked a turning point for the company and the industry.

“We had wanted to design and build a higher weight class tug for a long time, but it had to live up to the Best Tugs name,” explains Mark Patey. “Sierra is a culmination of technology, durability, and features that have never been seen on a tug in this class. We believe that a tug should be an extension of the plane…with durability to exceed our customer’s expectations.”

The Digital Model Delivers

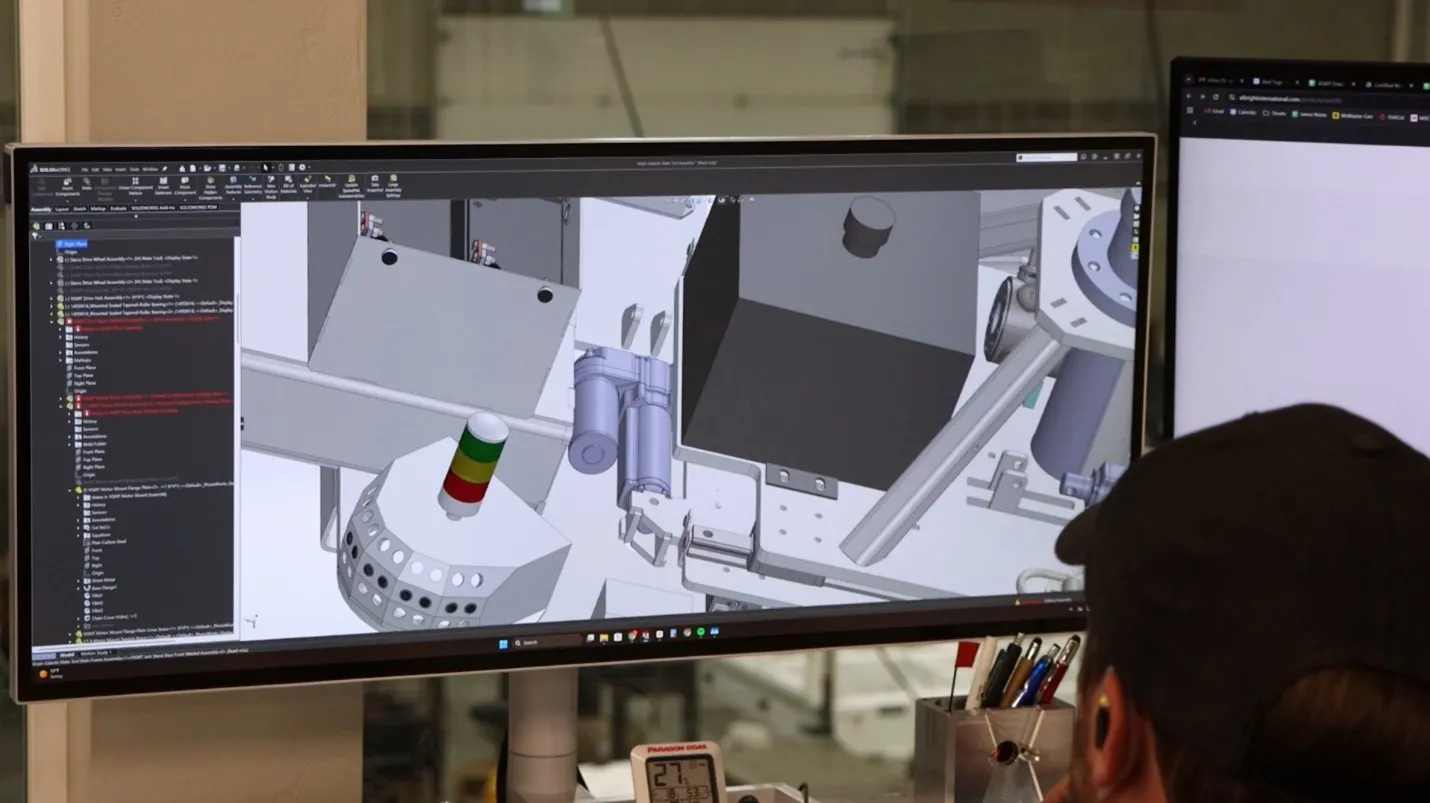

Every tug at Best Tugs is designed in SOLIDWORKS, which was chosen by Best Tugs not just for its capabilities, but for its cost-saving power in manufacturing.

“As a CEO, I look at it as time and money,” says Pratt. “When you can put something in a model and see that it's going to work or not going to work, you save so much time.” Using SOLIDWORKS helped the company to avoid costly mistakes before they ever happen, saving untold time and money.

Best Tugs isn’t just a product of good engineering. It’s the result of the Pateys’ commitment to make flying safer, easier, and more enjoyable for everyone. Every tug reflects the company’s mission: We Make Flying Easier and Safer.

Products:

- SOLIDWORKS Premium CAD

- SOLIDWORKS Simulation Premium

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.