Bio3DPrinting Takes a Giant Step Forward in Human Tissue Engineering

Dassault Systèmes SOLIDWORKS Extended portfolio plays a crucial role in the development of 3D bioprinting that uses a human patient’s cells to create a functional human organ.

Challenge

To develop a revolutionary new 3D bioprinting machine that creates living, three-dimensional tissue structures.

Solution

Implement SOLIDWORKS® Extended Portfolio to manufacture a ground-breaking 3D Printer designed to create life-like tissue which will handle real-world forces like weight, weather, and wear, and is engineered to provide the right mechanical, chemical, and biological conditions to support cell survival, organization, and development over time.

Results

- Design a new product from concept to production quickly

- Simplify the design to fewer parts for fewer mechanical errors

- Streamline the design from concept to final production model

- Manage every part within SOLIDWORKS

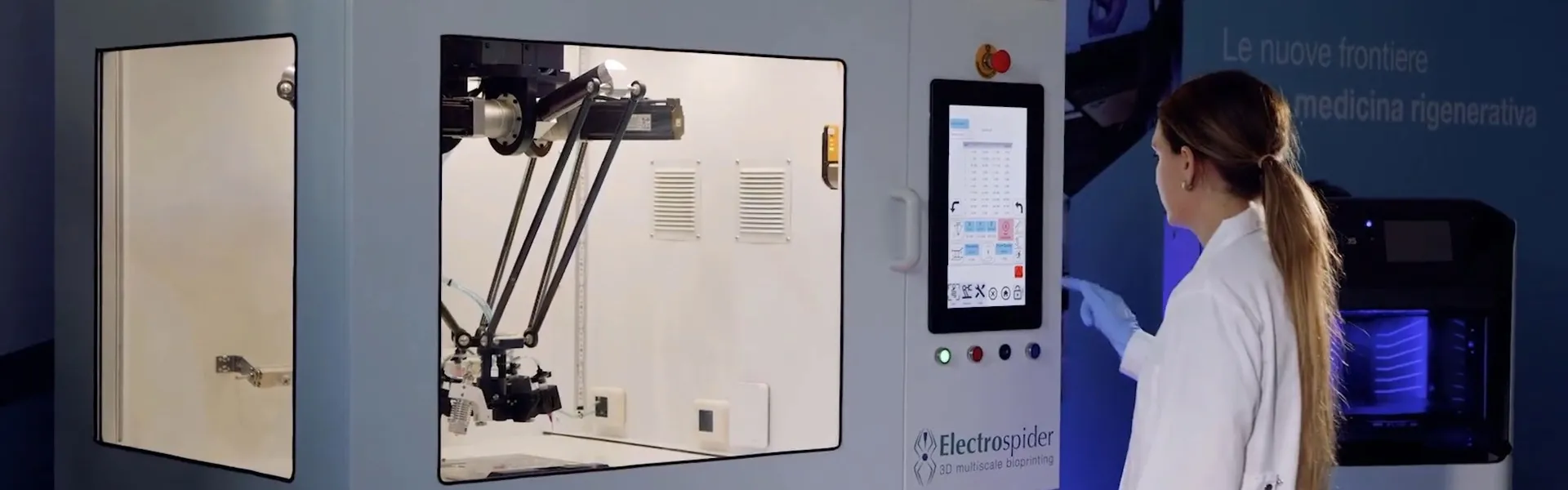

A collaboration between industry and academia, Bio3DPrinting was founded in 2021 to accelerate the commercialization of Electrospider technology, an idea that first emerged from research around 2010. Electrospider is a 3D bioprinting machine that creates living, three-dimensional tissue structures. It builds them layer by layer from a digital model, similar to traditional 3D printing.

“Instead of using materials traditional to 3D printing, we use biological materials like cells and biopolymers, sometimes called bioinks or biomaterial inks,” explains Aurora De Acutis, Bio3DPrinting President and researcher at the University of Pisa in Italy. “At the moment, these structures are used for drug development, testing new drugs, and personalized medical treatments.”

Bio3DPrinting’s Electrospider 3D bioprinter technology fabricates complex human tissue models using a single system. This breakthrough combines multiple bioprinting technologies into one cohesive workflow, a major leap forward in biofabrication, particularly for regenerative medicine, drug testing, and tissue engineering.

The Challenges of 3D Printing Biological Systems

Reproducing human tissues outside the body (in vitro) requires starting with scaffolds that mimic the extracellular matrix environment inside the body. These scaffolds provide physical and chemical support for cells, including a three-dimensional structure that can be populated by cells, allowing cells to adhere, proliferate, and mature.

Human tissues are complex, multi-material systems organized in a hierarchical structure spanning from nanoscale to microscale. This precise organization is essential to each tissue’s mechanical and biological function. “Replicating all these aspects is of fundamental importance when developing a scaffold so that it is as functional as possible,” explains De Acutis. “So the cells, once printed together with all the necessary biomaterials, can find a hospitable environment, favorable to their adhesion and proliferation.”

A scaffold is not just a physical frame that holds cells in place. It is a carefully engineered environment that actively influences how cells grow, move, multiply, and mature. Just like a bridge or machine must be designed to handle real-world forces like weight, weather, and wear, a bioprinted scaffold must be engineered to provide the right mechanical, chemical, and biological conditions to support cell survival, organization, and development over time.

Related Resources

“For us, SOLIDWORKS Extended portfolio played a crucial role in every aspect.”

Necessity is Still the Mother of Invention

One of the key motivations behind developing the Electrospider 3D bioprinter was the need for reliable and repeatable bioprinting. De Acutis recalls the fragmented process before Electrospider: “We started manufacturing the scaffold with a bioprinter capable of processing a biomaterial with a certain resolution, then we moved on to another [technology] to add parts in another biomaterial or use the same material with a different type of resolution.”

This fragmented workflow required multiple transitions between technologies and frequent human intervention, which often compromised the quality of the final construct, particularly when the output was intended for use in the human body.

The limitations of this approach led to the bold idea of designing a single bioprinter capable of simultaneously processing multiple biomaterials at varying resolutions with a goal of achieving true multiscale and multimaterial biofabrication. Streamlining the process minimizes errors and significantly improves consistency and quality.

The Right Product Development Tools

“For us, the SOLIDWORKS Extended portfolio played a crucial role in every aspect,” enthuses De Acutis. Bio3DPrinting is also working on incorporating artificial intelligence to monitor and control the bioprinting process in real time. The goal is to ensure that each step is precisely managed so the final bioprinted structures meet the rigorous standards needed for clinical applications.

De Acutis concludes, “It was amazing to think that simply by printing, I can save life.” That dream is what keeps Bio3dPrinting going in this field. The company hopes to see bioprinters installed in many hospitals and clinics in the future. The ultimate hope is to one day print complete organs to save human lives.

Products:

- SOLIDWORKS Premium CAD

- SOLIDWORKS Simulation Premium

- Collaborative Designer for SOLIDWORKS

- Collaborative Industry Innovator

Learn More About SOLIDWORKS

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.