Comptech Casts a New Path for the Foundry Industry

Foundry equipment maker uses SOLIDWORKS and the 3DEXPERIENCE platform to design advanced rheocasting systems that help foundries cut waste, save energy, and boost part integrity.

Challenge

Enable traditional high-pressure die casting (HPDC) foundries to upgrade their existing casting tools to semi-solid casting using a unique and highly effective approach to rheocasting without replacing their existing infrastructure.

Solution

Develop innovative new products from concept through final production using SOLIDWORKS Design tools and the 3DEXPERIENCE platform, which includes improvements to material performance, process stability, and sustainability.

Results

- Maintain a traceable digital thread from concept to manufacturing

- Team members can collaborate on the same design simultaneously

- Enable rapid iteration, reliable revision control, and faster delivery of designs

- Streamline workflow on bigger projects

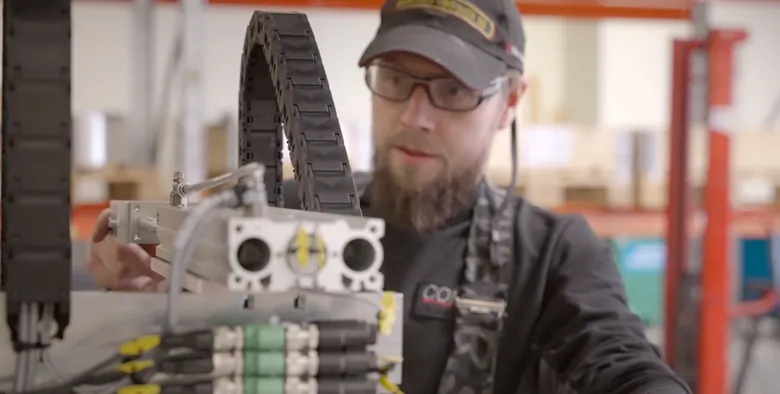

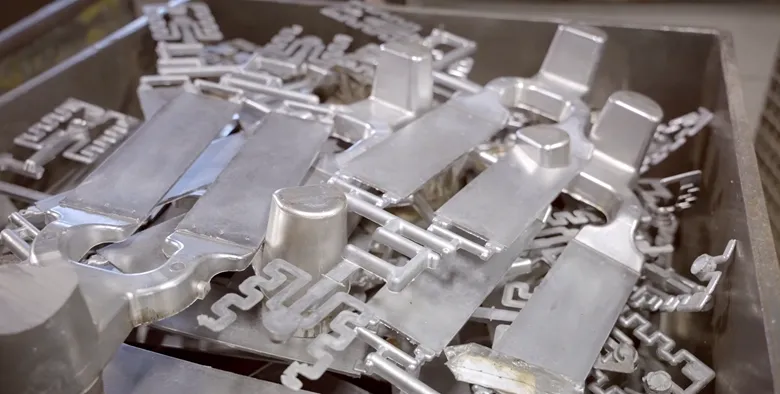

Comptech Rheocasting AB has evolved from modest roots in Sweden into a pioneer reshaping the foundry industry. Started in 1971 by CEO Per Jansson’s grandfather as a subcontracting shop, the company transformed over decades into an original equipment manufacturer (OEM) supplying advanced machinery to foundries worldwide. Rheocasting is a metal casting process that prepares a semi-solid metal (SSM) slurry directly from a liquid alloy, which is then injected into a mold to reduce shrinkage, defects, and improve mechanical properties.

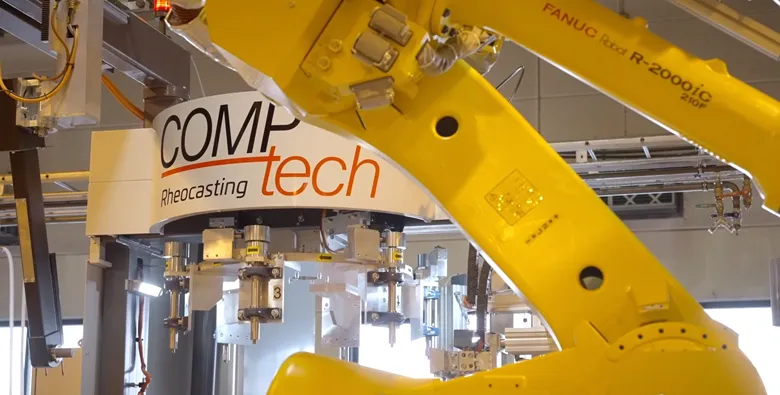

Today Comptech empowers traditional high-pressure die casting (HPDC) foundries to adopt semi-solid casting using its unique and highly effective approach to rheocasting, which includes improvements to material performance, process stability, and sustainability. “We produce equipment and technology for the foundry industry, helping to make existing high-pressure die casting foundries also become semi-solid casters,” explains Jansson.

Comptech describes its rheocasting method as a melt preparation HPDC process that enables the production of components with high integrity, high ductility, and low porosity, while also facilitating the use of secondary (recycled) aluminum alloys with a lower carbon footprint. This enables customers to upgrade their operations without replacing their existing infrastructure.

Marrying Tradition with Forward-Looking Engineering

Rather than discarding its customers’ existing HPDC setups, Comptech adapts and augments existing setups to realize the improved mechanical properties and stability of semi-solid casting. This pragmatic approach respects what currently works, while preparing foundries to meet future environmental and performance demands.

Jansson expects the shift toward greener aluminum alloys to accelerate. “We believe that the use of more environmentally friendly alloys is going to increase. The silicon content inside the alloys is one key takeaway,” he emphasizes. Controlling silicon content also improves process stability and reduces energy usage, two essential steps to remain competitive.

Related Resources

Before we used 3DEXPERIENCE, we had a lot of problems with revision control and misplaced files in our file catalogs. Now we can collaborate in the same design simultaneously. It has also really helped us in saving time searching for files that earlier were misplaced

Streamlining Development

Comptech depends on Dassault Systèmes SOLIDWORKS 3D CAD and 3DEXPERIENCE for innovative product development workflows that are both precise and helpful in optimizing delivery times. R&D engineer Emil Hedlund leads equipment development and helps customers plan their foundry layouts. “Before we used 3DEXPERIENCE, we had a lot of problems with revision control and misplaced files in our file catalogs,” he explains.

The 3DEXPERIENCE platform streamlines work on bigger projects. “Now we can collaborate in the same design simultaneously. It has also really helped us in saving time searching for files that earlier were misplaced,” he continues. Something as simple as easily locating files has reduced aggravating rework: Files that can’t be found must be redrawn because they’re needed for historical reference.

SOLIDWORKS and 3DEXPERIENCE enable Comptech to standardize designs, share updates instantly, and maintain a traceable digital thread from concept to manufacturing. That’s mission-critical when engineering intricate, one-of-a-kind rheocasting systems for customers.

Building the Future of Foundries

Jansson emphasizes that the future of HPDC lies in semi-solid casting using more sustainable alloys, lower energy input, and higher yield rates. Comptech’s integrated use of Dassault Systèmes SOLIDWORKS and the 3DEXPERIENCE platform enables rapid iteration, reliable revision control, and faster delivery of robust designs.

He concludes, “We are at the forefront of the technology…and I believe that SOLIDWORKS is one supplier that can help us grow.” Comptech is a great example of how blending traditional foundry know-how with modern technology can reshape an entire business.

Products:

- SOLIDWORKS Design Professional

- SOLIDWORKS Simulation Professional

- 3DEXPERIENCE Platform

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.