Elsewedy Electric PSP Powers Safer, Smarter Infrastructure with Simulation-Driven Design

Unified Modeling and Simulation on the 3DEXPERIENCE platform allowed Elsewedy Electric engineers to study structural performance, verify pressure and load conditions, and ensure compliance across diverse projects.

Challenge

Design and validate complex infrastructure systems from elevated monorail carts operating 25 meters above ground to high-pressure static equipment in power plants while ensuring safety, reliability, and compliance with international engineering standards. Traditional testing was costly, time-consuming, and difficult to perform under real-world conditions.

Solution

Use SOLIDWORKS Simulation to model, analyze, and optimize designs before production. Unified Modeling and Simulation on the 3DEXPERIENCE platform allowed Elsewedy Electric engineers to study structural performance, verify pressure and load conditions, and ensure compliance across diverse projects.

Results

- Validated monorail cart designs for safe, reliable operation at elevated heights

- Reduced design and testing time through virtual simulation

- Ensured code compliance for static equipment and pressure vessels

- Improved overall design accuracy, efficiency, and project delivery speed

- Enhanced collaboration and innovation for future energy and infrastructure projects

Elsewedy Electric is a global leader that has evolved from a local manufacturer of electrical products into an integrated energy and infrastructure solutions provider. Their inspiring journey started in 1938 as a trader in the electrical equipment business and has continued growing until today, with a strong presence in 19 different countries and 31 production facilities. They also export a wide range of high-end products to over 110 countries worldwide.

Mohamed Hussein is a Lead Mechanical Engineer at Elsewedy Electric. He holds a Master's degree in Mechanical Design and passed the Fundamentals of Engineering (FE) Mechanical Exam from NCEES. Hussein has over 10 years of experience in mechanical design and analysis, specializing in managing Static and Mechanical equipment. Elsewedy Electric uses simulation tools, such as SOLIDWORKS Simulation, to streamline operations and ensure project success in two unique cases: The Cairo Monorail and the Rabigh power plant in Saudi Arabia.

The Role of Simulation

In today’s engineering landscape, simulation is a powerful tool enabling teams to analyze and predict the behavior of complex structures and equipment. Elsewedy Electric recognizes simulation’s advantages, especially in cohesively handling different mesh element types.

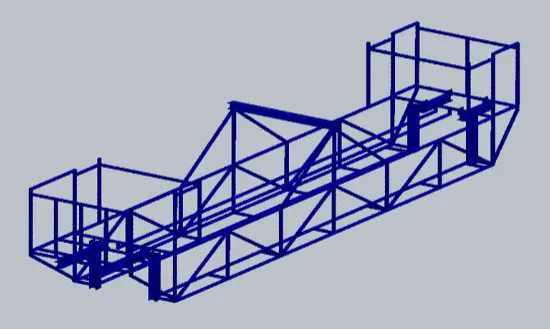

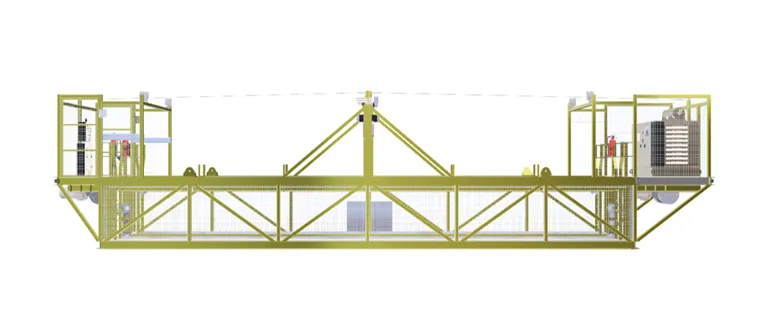

One of the key advantages of Unified Modeling & Simulation is the capability to address different challenges, allowing for a comprehensive analysis of complex systems, like the rail cart in the Cairo Monorail project. This capability allows Elsewedy Electric engineers to explore and validate designs before they reach the production stage, thereby minimizing potential issues in the field.

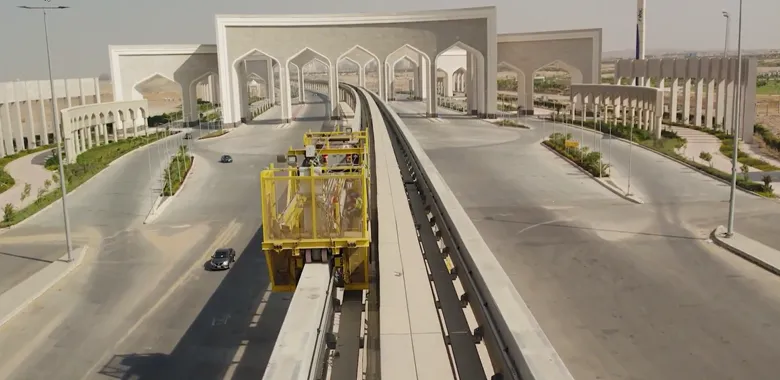

Safety and Reliability in Urban Projects

Simulation improves design accuracy and highlights Elsewedy Electric's commitment to safety and reliability, especially when executing projects in densely populated urban environments like Cairo. The team detailed the challenges posed by installing the Cairo monorail system, where construction is conducted at significant elevations. The monorail project aims to alleviate traffic congestion and improve mobility in the city, but it requires meticulous planning and execution. Design flaws in projects like the Cairo monorail have profound implications. The engineering team understands that even minor mistakes could lead to substantial public safety hazards or operational failures in the urban context. Therefore, simulation is crucial in validating every design aspect before implementation.

Related Resources

Simulation is an essential part of our design process, supporting various aspects of our work. We handle a diverse range of equipment, where we conduct different types of analysis, validate results, and ensure compliance with design codes and standards.

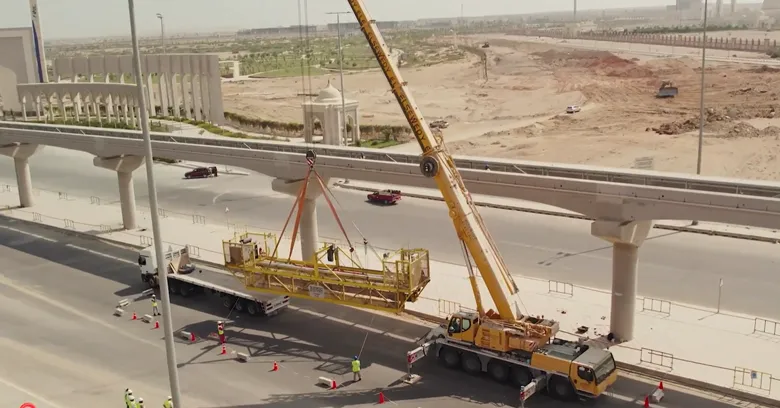

The engineering team's primary challenge for the Cairo monorail system was performing construction activities at heights of up to 25 meters. In this scenario, traditional scaffolding methods are impractical, leading Elsewedy to develop specialized carts for their elevated work. This innovation highlights the importance of simulation in facilitating the design of these unique solutions, ensuring that both the construction methods and the final product adhere to the highest engineering standards. “Simulation allowed us to test a wide range of loading conditions, including extreme cases that may be difficult, unsafe, or expensive to replicate in physical testing.”, states Hussein.

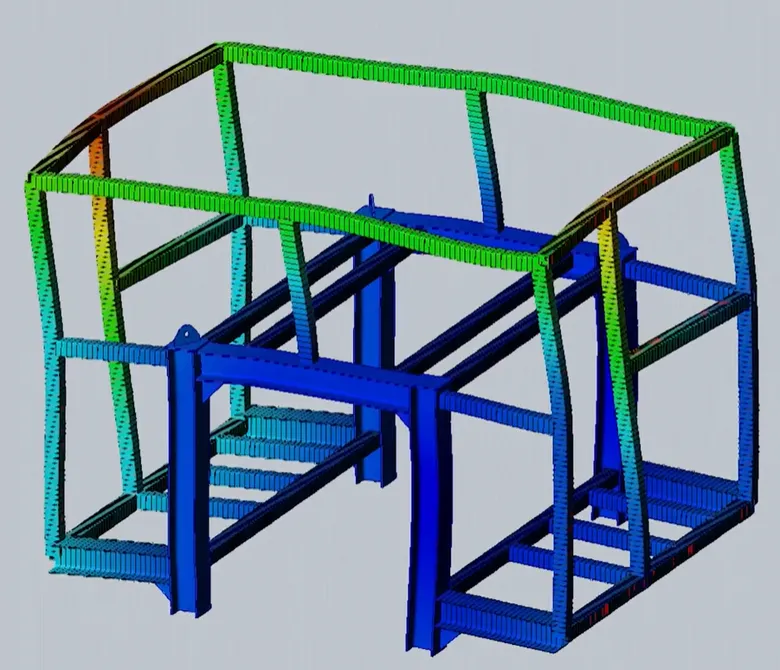

Elsewedy conducted structural analysis of the carts, evaluated their stability, designed the connections, and studied structural behavior under special conditions such as lifting. Additionally, they analyzed the wheel structures to ensure optimal performance. This enabled the team to study the effects of sudden impacts and vibrations on the cart’s frame and wheels. Without simulation, achieving results in the Cairo monorail project would have taken much longer than it did. Three years after implementing the project, all 24 carts are now successfully in operation.

Comprehensive Approach to Static Equipment

The team also spoke about Elsewedy Electric’s static equipment (machinery or devices that remain stationary and have no moving parts during normal operation) projects, such as those undertaken for the Rabigh power plant in Saudi Arabia. Here, the team oversees the entire lifecycle of static equipment, from specifications to testing and commissioning. They are using simulation for the design of storage tanks' internal structures, the verification of nozzle loads of specific pressurized equipment, and the design of flanges. Sometimes, they use simulation to design vessel supports, ensuring their reliability against the working loads. This comprehensive approach streamlines the process and ensures that the end products, including pressure vessels and heat exchangers, meet stringent industry standards.

The design of static equipment presents its own set of challenges. The complexity arises from the need to account for various variables such as pressure, temperature and fluid dynamics. Failures in pressure-related equipment can result in catastrophic emergencies with storage tanks due to their large size, leading to environmental disasters and even loss of life. The team emphasized that simulation allows engineers to gain critical insights into the behavior of these systems under real-world conditions, facilitating more effective designs tailored to specific operational requirements. “Static equipment helps Elsewedy Electric comply with code or standard requirements. Many design codes and standards (e.g., ASME, API) require simulations for some cases, ensuring compliance early in the process,” says Hussein.

Conclusion

In conclusion, Elsewedy Electric's commitment to utilizing cutting-edge simulation tools significantly enhances its engineering capabilities. By embracing technologies like SOLIDWORKS Simulation, they ensure designs that meet and exceed industry standards in safety, reliability and efficiency. As Elsewedy Electric continues to innovate and evolve, its emphasis on simulation will undoubtedly play a crucial role in shaping the future of energy and infrastructure solutions. Elsewedy is currently collaborating with Dassault Systèmes to explore values delivered by SIMULIA structural and fluid simulation solutions on the cloud-based 3DEXPERIENCE Platform, for their advanced simulation needs in upcoming projects.

Products

- SOLIDWORKS Standard

- SOLIDWORKS Simulation

- SIMULIA

- 3DEXPERIENCE Platform

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.