Filtr8 Builds an Efficient and Sustainable Air Purification System

Device innovator leverages SOLIDWORKS Flow Simulation to optimize airflow, validate performance, and design a recyclable LED-based air purification system.

Challenge

Create an air purification device that could neutralize airborne bacteria using advanced LED technology to eliminate bacteria without relying on traditional bulbs.

Solution

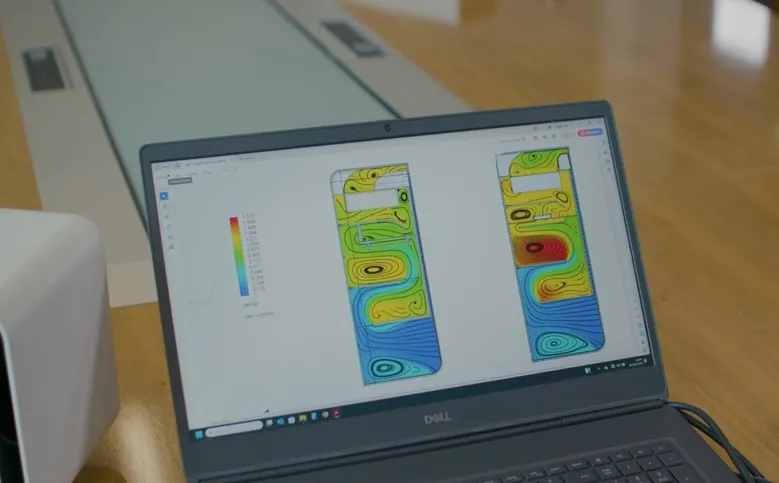

Using Dassault Systèmes SOLIDWORKS Flow Simulation to identify ways to improve the internal airflow. This would allow modifications of the design to be made easily.

Results

- Boosted the efficiency of the product by 20%

- Simulate real-world performance before updating the prototype

- Calculate the efficiency of the product within CAD

- Reduced time to market

The COVID-19 pandemic spurred Dave Crofts, CEO of Filtr8 and inventor of the company’s signature air purification device, to create a solution that could neutralize airborne bacteria using advanced LED technology. The team began with a simple prototype—a box and a fan—but they had a clear goal: Design a product that would eliminate bacteria without relying on traditional bulbs.

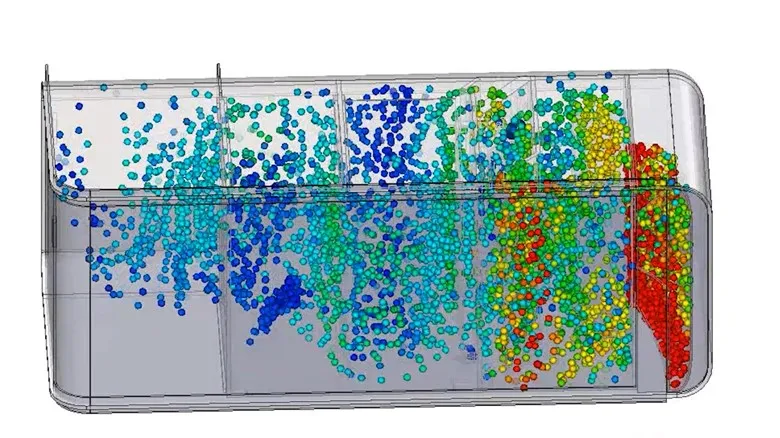

Crofts and his team knew that efficacy depended on controlling how long air stayed inside the device. “We had to somehow create a residence time within the device to make it efficient in neutralizing bacteria and anything else that went through the device,” explains Croft. The concept evolved with the integration of smart sensors that enabled monitoring of particle levels and adjustment of system behavior in real time. The sensors could also detect the types of bacteria or particulates within a room.

Validating Product Performance

Julian Feick, Filtr8’s Technical Manager, spearheaded bringing the prototype to production. Feick realized immediately on joining the company that although the physical design was promising, the team lacked the ability to validate its performance. An initial third-party lab test, which cost nearly £30,000, yielded disappointing results, prompting a strategic pivot.

Related Resources

SOLIDWORKS Flow Simulation was a fantastic eye-opener. Seeing something we created come to life in simulation—and watching others use those tools to describe and demonstrate how it works—was amazing.

The next logical next step was to reevaluate the design in the virtual world.

Using Dassault Systèmes SOLIDWORKS® Flow Simulation, the team identified opportunities for improving the internal airflow. “We had to tweak things, constantly calculating the airflow,” details Crofts. These changes boosted the overall system efficiency by more than 20%. “We were able to make modifications and see the benefits [in SOLIDWORKS Flow Simulation] straight away,” enthuses Crofts.

Filtr8 also modeled the device’s performance in real-world environments, allowing them to track how contaminated air moved through a room and how best to recapture it. Using SOLIDWORKS Flow Simulation, the development team was able to calculate how long it would take to change the quality of the air within a certain-size room. According to Crofts, this capability “transformed our whole thinking,” and from that point forward the product quickly moved to the final design phase.

Sustainability Matters

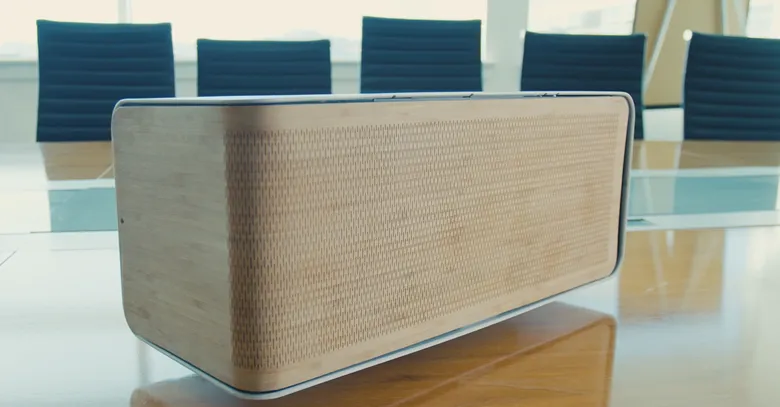

Filtr8 chose an industrial design firm that uses SOLIDWORKS that could review the actual simulation results, interpret them, and incorporate them into the product. These insights informed the final design, which emphasized both performance and sustainability. The industrial designers also built a product that was both modern and timeless. The front panel is made of bamboo and its plastic casing includes bamboo filler, resulting in a unit that is 89% recyclable.

Crofts was particularly impressed by the design insights unlocked through simulation: “SOLIDWORKS Flow Simulation was a fantastic eye-opener. Seeing something we created come to life in simulation—and watching others use those tools to describe and demonstrate how it works—was amazing.”

“We now know we’ve achieved the maximum performance we can from this device, and that it works,” concludes Crofts. “Thanks to [Dassault Systèmes] SOLIDWORKS, we have the final product and are looking for investment to take it to the next level.”

Products Used:

- SOLIDWORKS 3D CAD

- SOLIDWORKS Simulation Premium

- SOLIDWORKS Flow Simulation

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.