FloFleet Speeds Development, Reduces Costs, and Enhances Collaboration

Innovative helium airship Startup Company develops its products more quickly and economically with SOLIDWORKS and 3DEXPERIENCE Works solutions.

Challenge

Quickly develop a drone-like, solar-powered, helium floating airship with extended flight autonomy of at least a week of flight, zero emissions, and the ability to carry payloads of up to 8 kg (17.5 pounds)

Solution

Implement modeling, design, data management, simulation, collaboration, and communication solutions from the 3DEXPERIENCE® Works portfolio, which operate on the cloud-based 3DEXPERIENCE platform—including 3D Creator, 3D Sculptor, 3DEXPERIENCE SOLIDWORKS® Premium, 3DEXPERIENCE SOLIDWORKS Simulation Designer, Collaborative Designer for SOLIDWORKS, Collaborative Industry Innovator, Project Planner, 3DEXPERIENCE Works Learner, Social Business Analyst, and 3DSwymer roles—as part of the 3DEXPERIENCE Works for Startups Program

Results

- Accelerated airship development

- Reduced development costs

- Eliminated repetitive prototyping cycles

- Enhanced collaboration

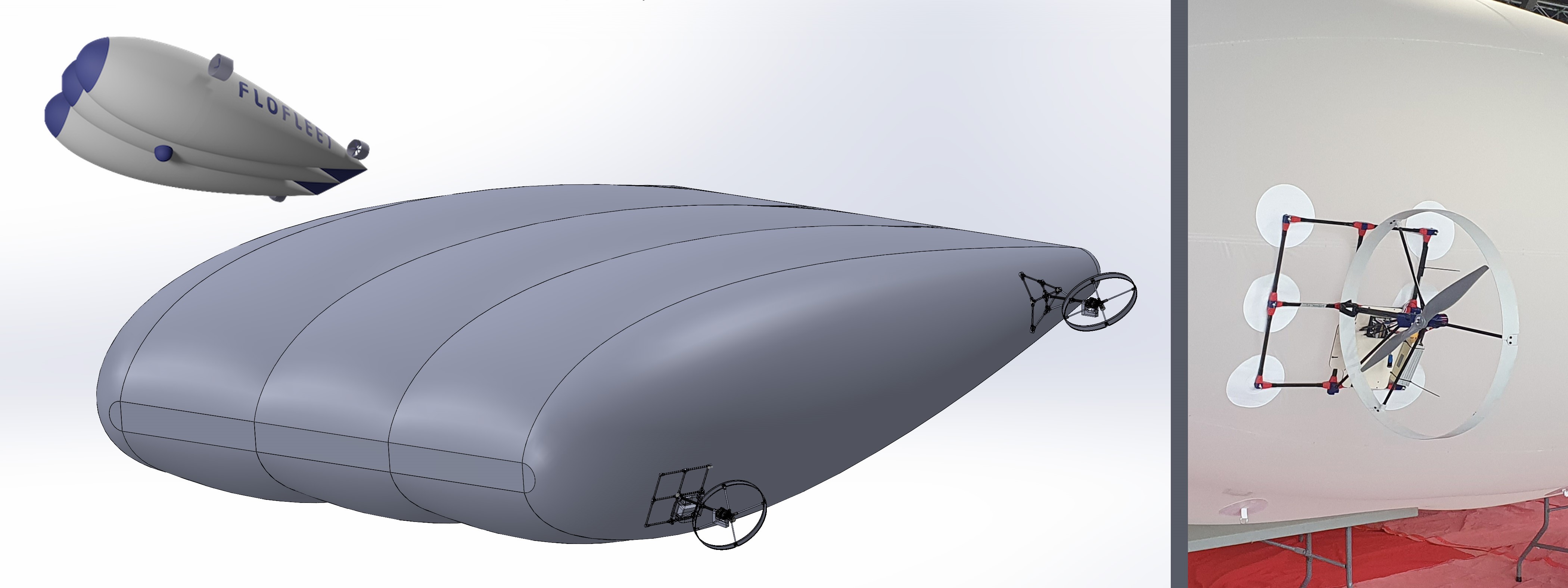

Italian startup FloFleet S.R.L. is developing a solar-powered floating helium airship that can remain in flight for a week and carry payloads of up to 8 kg (17.5 pounds) with zero emissions. While overcoming the limitations of traditional drones and replacing the expense and fossil fuel emissions of helicopters, FloFleet airships will carry heavier payloads while enabling longer-term infrastructure surveillance, disaster assessments, search and rescue, event streaming, agriculture, and cartography with flights of over 200 km (124 miles).

The innovative, inflated-wing shape not only provides aerodynamic lift but also allows more surface area for solar panels. The airships are completely autonomous, so they don't require a pilot, not even from the ground.

FloFleet CEO Andrea Cecchi founded the startup in mid-2022 after completing a thesis on stratospheric platforms. The FloFleet airship is filled with helium and travels via four electric motors powered by solar panels on top of the aircraft. The vehicle control devices, cameras, thermal imaging cameras, and other sensors can be installed in the lower part of the airship. FloFleet’s design and engineering team members learned SOLIDWORKS® design software as students at Politecnico di Milano, so it was an easy decision to leverage solutions from the 3DEXPERIENCE® Works portfolio that operates on the cloud-based 3DEXPERIENCE platform—all a part of the 3DEXPERIENCE for Startups program.

Testing in a Virtual Environment

To solve the considerable engineering challenge of defining the volumes and surfaces of the aircraft along with achieving the correct balance between load capacity, autonomy, and weight, the team relied on the 3DEXPERIENCE SOLIDWORKS Simulation Designer. “As a startup, we do not have large economic resources available to invest, and we have found the software simulation offered by the Startup Program an excellent solution for modeling the airship and carrying out tests and evaluations in a virtual environment,” Cecchi stresses.

Related Resources

One of the first problems we faced was related to the volume of the airship, a fundamental variable for making it fly. It’s necessary to achieve balance between the volume and surfaces for aerodynamics, taking into account the presence of upper surfaces where the solar panels are installed, and the availability of an adequate volume for helium that is capable of ensuring the correct aerostatic thrust. The 3DEXPERIENCE Works modeling and simulation tools helped us solve this challenge by evaluating the best-performing geometries.

Enhancing Collaboration and Speeding Development

With the transparent 3DEXPERIENCE data management solution in the cloud, the design team accurately modeled every part of the airship, including the engines, supports, and sensors, and then assigned each the relevant material and mechanical characteristics to evaluate their behavior. “This not only allowed us to reduce costs but also speeded up the subsequent development phases,” Cecchi notes.

3DEXPERIENCE Works solutions enhanced the FloFleet team’s collaboration and spurred development because they enable collaboration even when team members work in different locations. CTO Andrea Buson notes, “In fact, the license is not associated with the single computer but with the user; therefore, with a simple login on the portal, it can be downloaded on multiple machines."

By utilizing 3DEXPERIENCE Works solutions, FloFleet accelerated airship development, reduced development costs, eliminated repetitive prototyping cycles, and enhanced collaboration. FloFleet completed its proof-of-concept prototype in late 2022 and delivered its first commercial version in 2024. “We continue to use 3DEXPERIENCE Works solutions at FloFleet both because it is a complete software and a very powerful suite, of which we will probably also use other applications in the future, and because it has proven to be very flexible,” Buson concludes.

Learn More About SOLIDWORKS

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.