GRIND Changes the Game in Sports Training Equipment

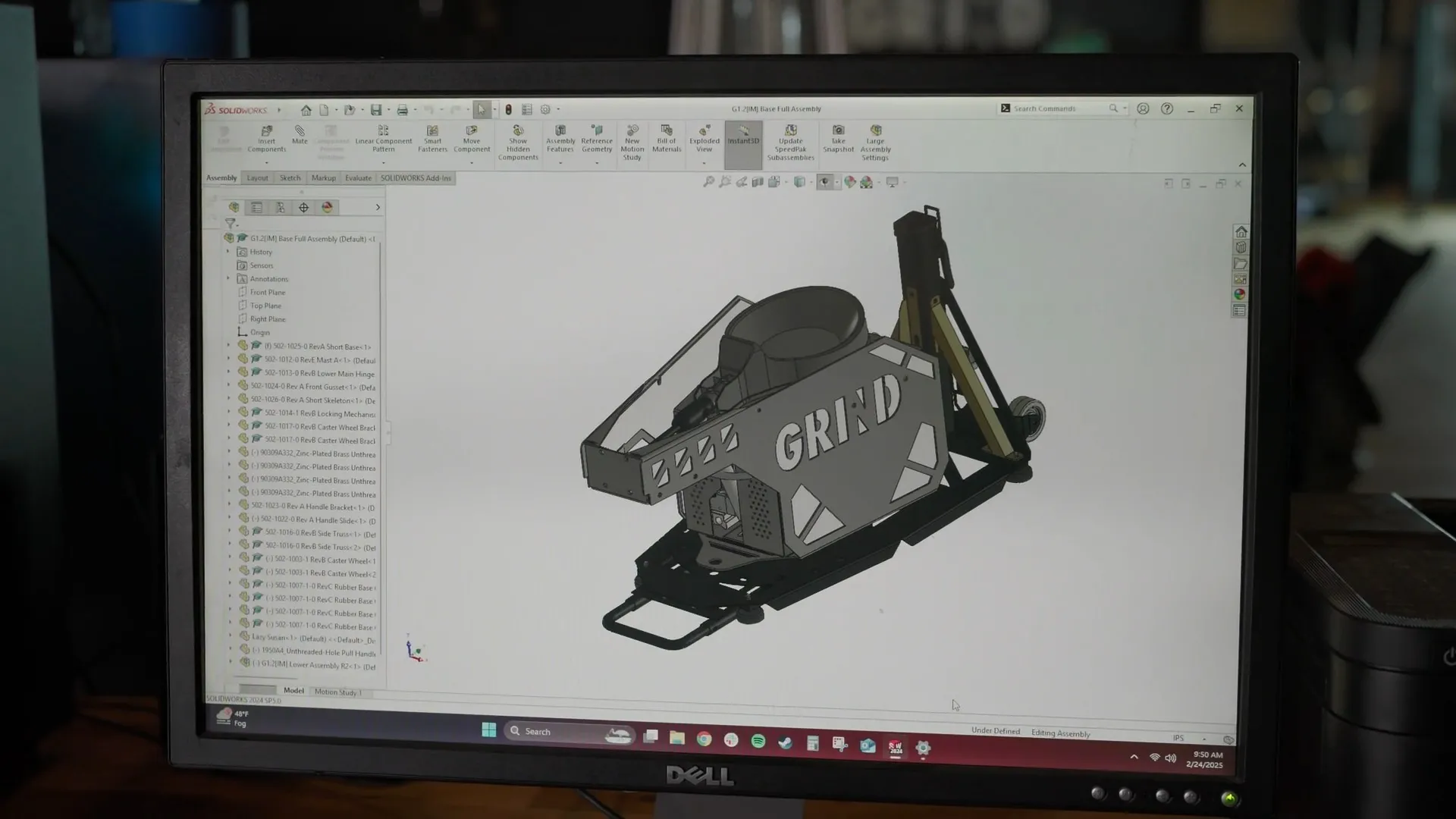

GRIND leveraged SOLIDWORKS to transform an initial concept into a fully functional, manufacturable product and disrupt an industry dominated by expensive, industrial-grade machines.

Challenge

Develop the world's first portable basketball shooting machine that redefines the industry.

Solution

Using SOLIDWORKS CAD Design tools to accelerate the design, prototyping, redesign, and preparation for manufacturing processes.

Results

- Developed an entirely new product and industry from scratch

- Accelerated the design through the manufacturing process

- Enhance overall efficiency from aesthetic design through manufacturing

- Minimize the number of parts to streamline production

Bringing a new product to market is a significant challenge, especially a product that redefines an industry. For Thomas Fields, founder and CEO of GRIND, the journey to developing the world's first portable basketball shooting machine was fueled by passion for sports and an innovative vision.

GRIND leveraged SOLIDWORKS®, to transform an initial concept into a fully functional, manufacturable product and disrupt an industry dominated by expensive, industrial-grade machines.

Taking Practice Efficiency to a Whole New Level

“Every serious basketball player aims to take between 500 and 1,000 shots a day to improve their skills. That’s how legends like Steph Curry and Larry Bird trained,” says Fields. “The problem is, manually shooting that many shots can take five to six hours. Our shooting machine reduces that to just one hour, making high-volume training much more efficient.”

Before GRIND arrived on the market, shooting machines were large, costly, and typically limited to educational and professional facilities. “Before we came along, most basketball shooting machines were bulky, industrial-grade equipment used in high schools, colleges, and the NBA. They were expensive and inaccessible to most athletes,” explains GRIND Industrial Designer and Adjunct Professor at the University of Houston Elliot Martinez. “But as technology advances, products get smaller and more affordable. GRIND did exactly that for basketball training.”

Related Resources

SOLIDWORKS was a game-changer for us.

We could start with something as simple as a sketch on a napkin or a photo from Instagram, then quickly bring it to life in SOLIDWORKS. The software allowed us to rapidly prototype using laser cutters and 3D printing. Once we had a working prototype, we converted it into technical drawings for production. Having all these tools in one software made our process seamless

The Birth of an Idea

Fields’ personal experiences shaped and inspired his innovation. “I played basketball in high school and had the potential to go further, but I tore my ACL four times before graduating,” he recalls. “At that point, I realized a huge problem—I didn’t have access to the same $10,000, 400-pound shooting machines at my school.” Fields wondered if there were other shooting machines on the market that were less expensive and less bulky.

Determined to solve this problem, Fields built his first prototype in his parents’ garage with the help of a friend who taught him how to weld. “Our first prototype wasn’t pretty. We even called it ‘the ugly baby,’” Fields jokes. “But it worked. Then I teamed up with Elliot, my co-founder, who took that rough concept and refined it into a product that thousands of athletes use today.”

Engineering the Solution with SOLIDWORKS

Once the proof of concept was established, GRIND needed a way to refine and manufacture the product efficiently. “SOLIDWORKS was a game-changer for us,” notes Martinez. “My background in mechanical engineering and industrial design gave me the skills to use SOLIDWORKS.” Martinez did all the modeling—from surfacing to rendering—and developed products that were ready to be manufactured.

Martinez highlights how SOLIDWORKS’ parametric design capabilities streamlined the product development process: “We could start with something as simple as a sketch on a napkin or a photo from Instagram, then quickly bring it to life in SOLIDWORKS. The software allowed us to rapidly prototype using laser cutters and 3D printing. Once we had a working prototype, we converted it into technical drawings for production. Having all these tools in one software made our process seamless.”

The ability to iterate rapidly and fine-tune the design was crucial. “We gathered extensive feedback from users, tested the machine ourselves, and identified areas for improvement along the way, recalls Martinez. By continuously refining and improving their approach, the GRIND team was able to evolve the initial idea into a significantly better, more effective product.

Innovating for the Future

GRIND’s most recent iteration includes enhanced features. “The latest machine now offers nine passing spots on the court—four more than our previous model,” explains GRIND’s Chief Marketing Officer Amry Fields. “Players can now shoot from a wider range of spots, including the free-throw line, deep corners, and the top of the key [the area furthest from the basket in the free-throw circle].”

Martinez chimes in, “We also redesigned the netting system to improve durability and reduce setup time. Since netting absorbs impact from every shot, we reinforced the high-impact areas to ensure greater longevity. Our goal is to keep athletes focused on training, not on making constant adjustments.”

Despite these product upgrades, GRIND continues to be the most affordable shooting machine on the market.

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.