Industrilås Innovates Its Way from Garage to Global Leader

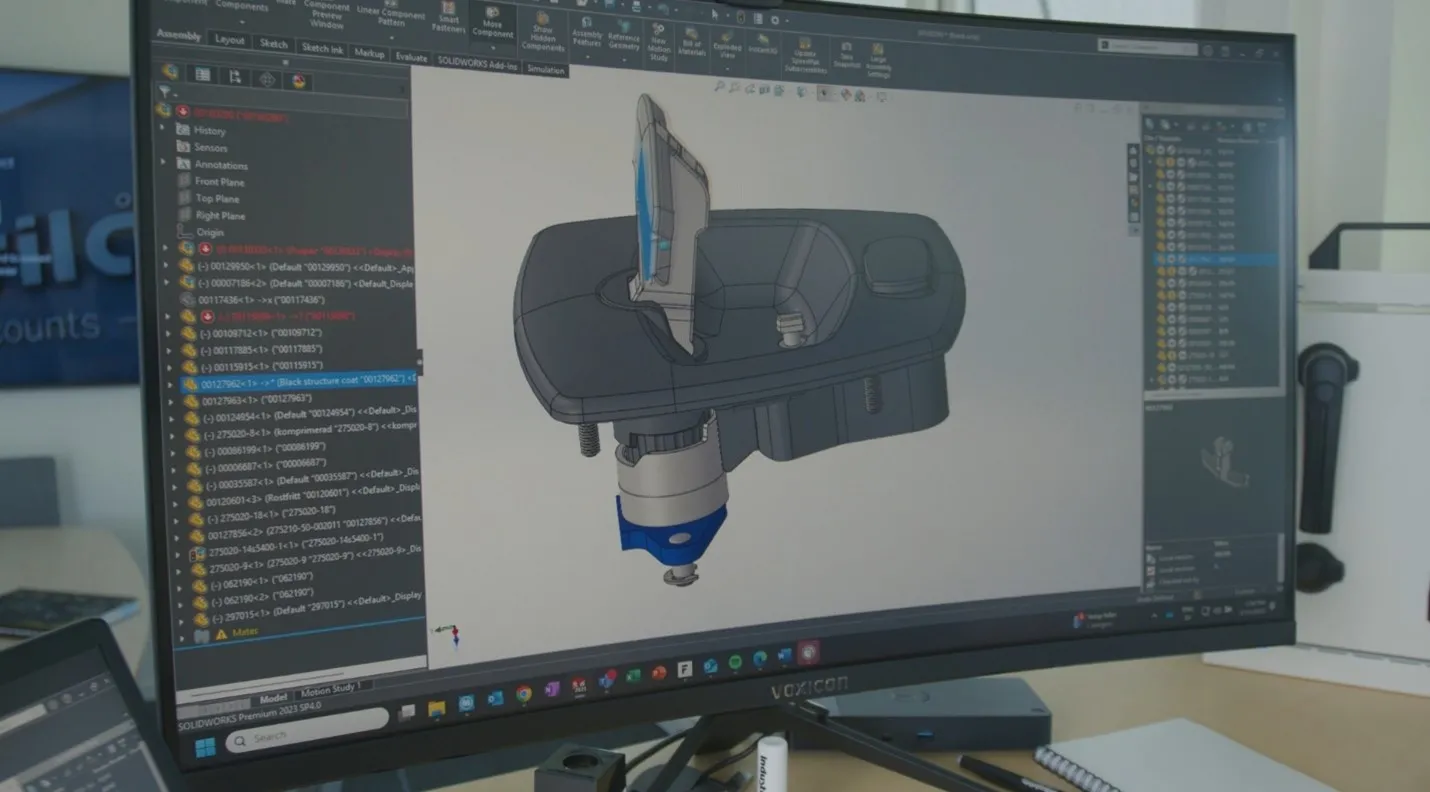

By integrating SOLIDWORKS into its innovation infrastructure, hardware manufacturer optimizes design efficiency, ensures product quality, and supports global scalability.

Challenge

To manage and develop thousands of parts for a large production facility that produces handles, latches, hinges, and seals that keep industrial enclosures secure and airtight

Solution

SOLIDWORKS® is a part of every step of in-house production, from design and construction to zinc casting, injection molding, and final assembly for products that turn ordinary doors into robust access systems for demanding environments.

Results

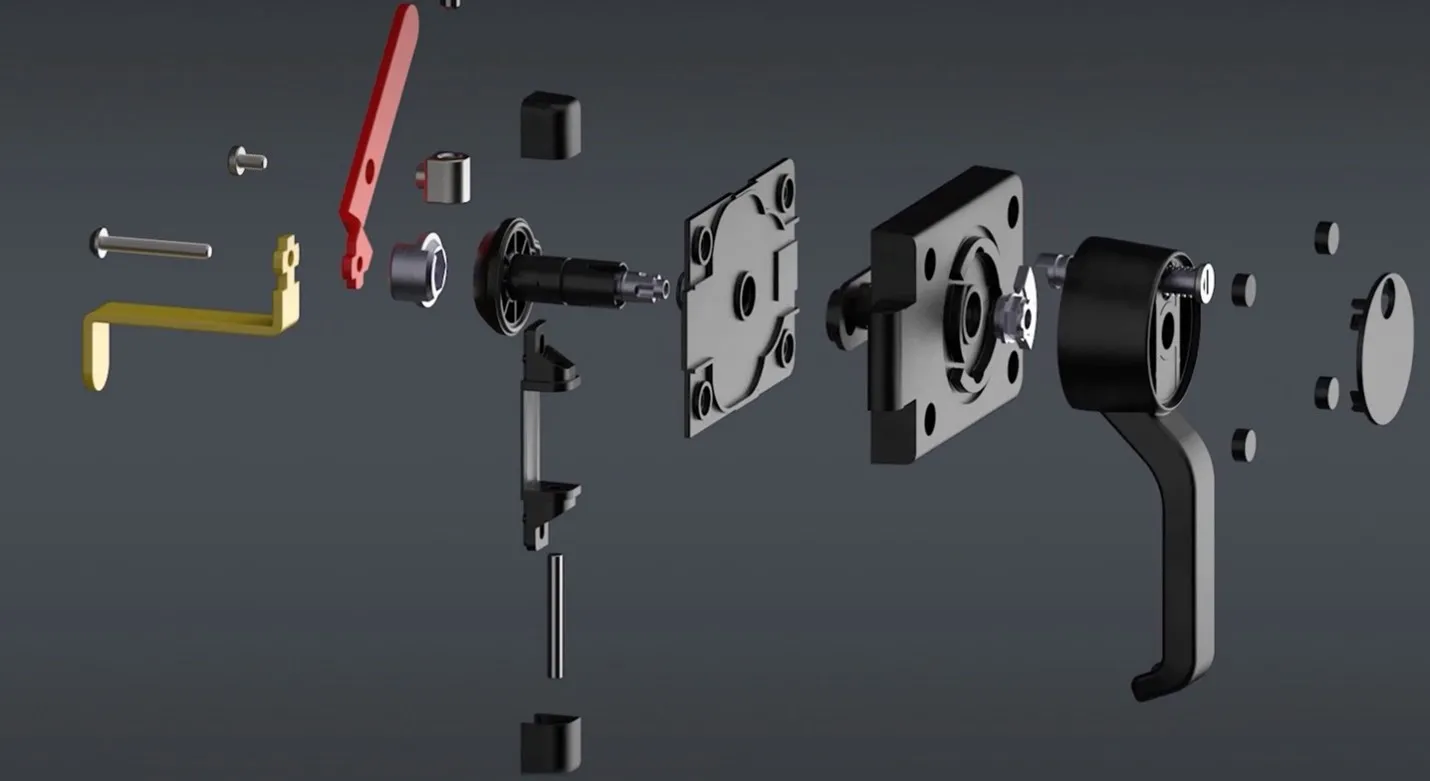

- Easily design for the manufacturability of thousands of parts

- Simplify the design to fewer parts for fewer mechanical errors

- Innovation of every new part starts in SOLIDWORKS

- Manage every part within SOLIDWORKS

Industrilås makes handles, latches, hinges, and seals that keep industrial enclosures secure and airtight. They turn ordinary doors into robust access systems for demanding environments. “Industrilås was started 40 years ago by my father who recognized a need in the market to improve the general locking and sealing technologies in those days,” recalls Fredrik Mölzer, Owner and CEO. Mölzer’s father started the business from their home garage.

From the beginning, innovation and adaptability have been core to Industrilås’ DNA. Manual equipment and drawing boards set the pace early on, but it didn’t take long to recognize that a different approach was needed. “We have always been very curious by nature. I think that's one of our driving forces, and we are quick to adopt new technologies,” Mölzer adds. That curiosity led Industrilås to SOLIDWORKS, a decision that would forever shape the company’s engineering and manufacturing strategy.

Building an Engineering Powerhouse

Today Industrilås employs about 500 people worldwide with engineering teams in multiple geographic locations, including two in Sweden, and four manufacturing sites on four continents. Every step of production, from design and construction to zinc casting, injection molding, and final assembly, is done in-house. This level of vertical integration ensures complete control over quality, performance, and delivery timelines.

Related Resources

My favorite thing with SOLIDWORKS is I can put whatever I have in my brain and design it in a computer and make everybody else understand what I do.

Engineering Manager Bengt-Åke Alfredsson has been working with SOLIDWORKS since his school days. “My favorite thing with SOLIDWORKS is I can put whatever I have in my brain and design it in a computer and make everybody else understand what I do,” he explains. That ability to communicate complex ideas visually has become central to Industrilås’ product development process, especially with custom solutions where customer requirements drive the design.

SOLIDWORKS as a Strategic Partner

SOLIDWORKS is not just a tool; it is an essential part of Industrilås’ innovation infrastructure. Mölzer emphasized that SOLIDWORKS is deeply integrated into their product development process, serving not only as a core design tool but also as a trusted partner in the company’s broader innovation process.

The partnership dates back nearly three decades. In fact, Industrilås was one of the first companies in Scandinavia to adopt SOLIDWORKS, which allowed them to show customers 3D models when competitors could only present 2D drawings. Early adoption of SOLIDWORKS set Industrilås apart in technical sales and strengthened customer relationships.

In-House Manufacturing Excellence

By having every major manufacturing process performed all under one roof, Industrilås controls the entire product lifecycle, from design to finished assembly.

The design and construction team translates customer requirements into manufacturable products, while the quality department validates performance through rigorous testing for waterproofing, dustproofing, durability, and usability. The in-house tool department builds and maintains the specialized tools needed for production, eliminating dependency on outside suppliers. Manufacturing capabilities span CNC turning, zinc die casting, injection molding, PUR gasketing, punching, bending, drilling, threading, powder coating, and final assembly.

This comprehensive setup ensures faster response to customer needs, tighter quality control, and greater freedom to innovate. Instead of being constrained by supplier limitations, Industrilås can experiment, refine, and scale product solutions internally to better serve their customers’ needs.

Sustainability at the Core

Industrilås’ manufacturing excellence is matched by their commitment to sustainability. “We are aware of our responsibility towards people, nature, and the climate. Therefore, we work hard every day to develop our business and find new solutions for an increasingly sustainable tomorrow,” emphasizes Mölzer.

Recent initiatives include switching to climate-effective zinc produced entirely with renewable energy, which reduces emissions from zinc production by 43% without impacting product quality. The company also provides emission data and life cycle assessments for products made at its largest site in Nässjö, Sweden, adhering to worldwide standards for greenhouse gas emissions.

Sustainability extends beyond materials. With manufacturing sites strategically located across continents, Industrilås shortens supply chains, improves on-time delivery, and lowers transportation emissions. Its packaging materials are fully reusable or recyclable, and waste materials from manufacturing are reused whenever possible.

Looking Ahead

Industrilås continues to invest in capacity, including a brand-new factory in Nässjö that will double production space and further integrate sustainable practices. SOLIDWORKS continues to enhance the company’s design and innovation capabilities, strengthening its foundation for continued growth.

“It was the right decision to go with SOLIDWORKS,” concludes Mölzer. “The way the journey has been so far only tells me that we will be even more closely integrated with SOLIDWORKS into the future.”

Learn More About SOLIDWORKS and 3DEXPERIENCE Work

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.