Toshiba Innovates Packaging for Speed, Cost, and Sustainability

Toshiba Innovates Packaging for Speed, Cost, and Sustainability

Challenge

Minimize lengthy, costly rounds of prototype testing to shorten time to market while ensuring quality and reducing the use of plastics in logistics packaging products.

Solution

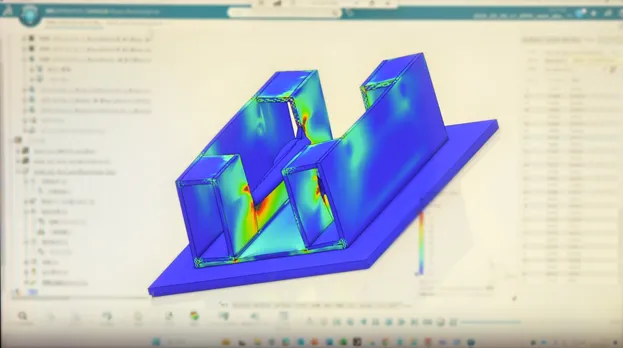

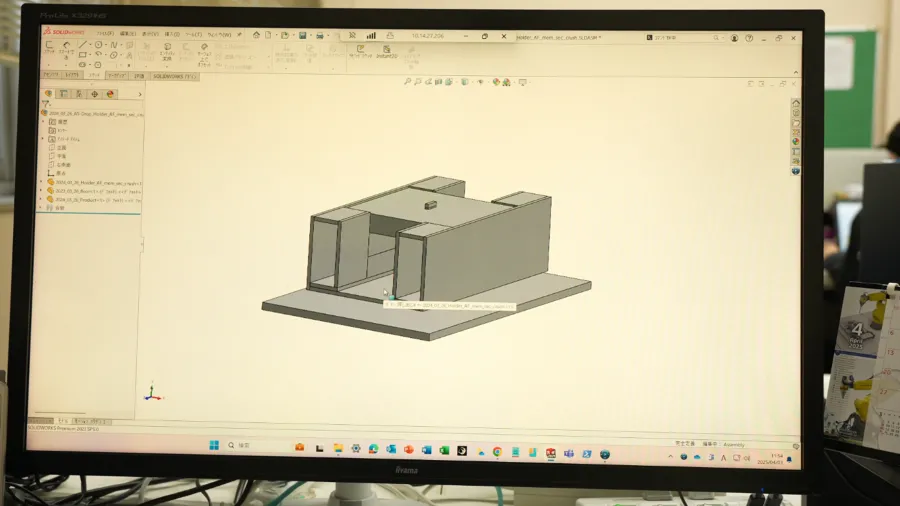

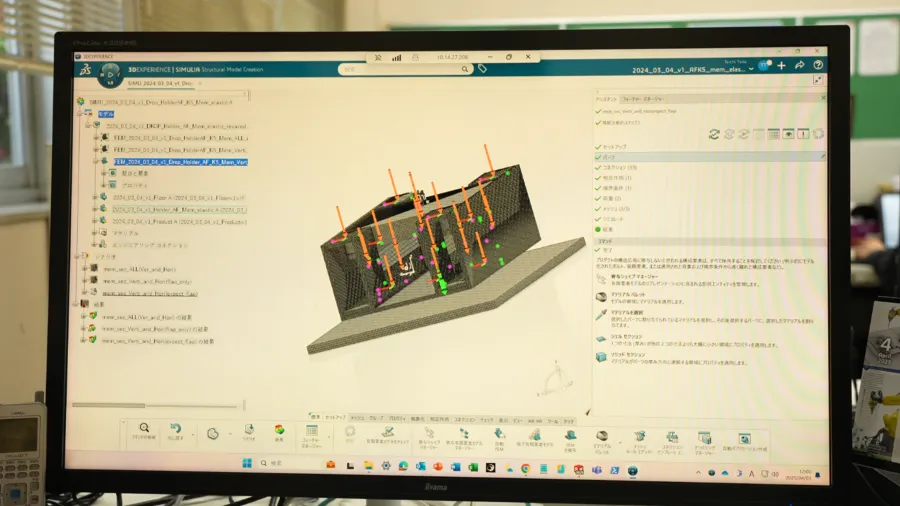

Add the 3DEXPERIENCE Structural Mechanics Engineer simulation solution and SOLIDWORKS Cloud Services for accessing the cloud-based 3DEXPERIENCE platform to its existing SOLIDWORKS installation in order to perform advanced structural analyses in the cloud.

Results

- Minimized lengthy, costly rounds of prototype testing

- Shortened lead times and reduced unnecessary costs

- Innovated use of unique packaging materials

- Improved quality through optimized designs

SBS Toshiba Logistics, headquartered in Kanagawa, Japan, has long been known as the logistics backbone of the Toshiba Group, reliably reducing costs and ensuring smooth supply chain operations. Over the years, the company expanded beyond its parent group to offer logistics solutions across industries from consumer goods to semiconductors. What sets them apart today is not just their logistics expertise but their willingness to rethink packaging design with the help of simulation tools.

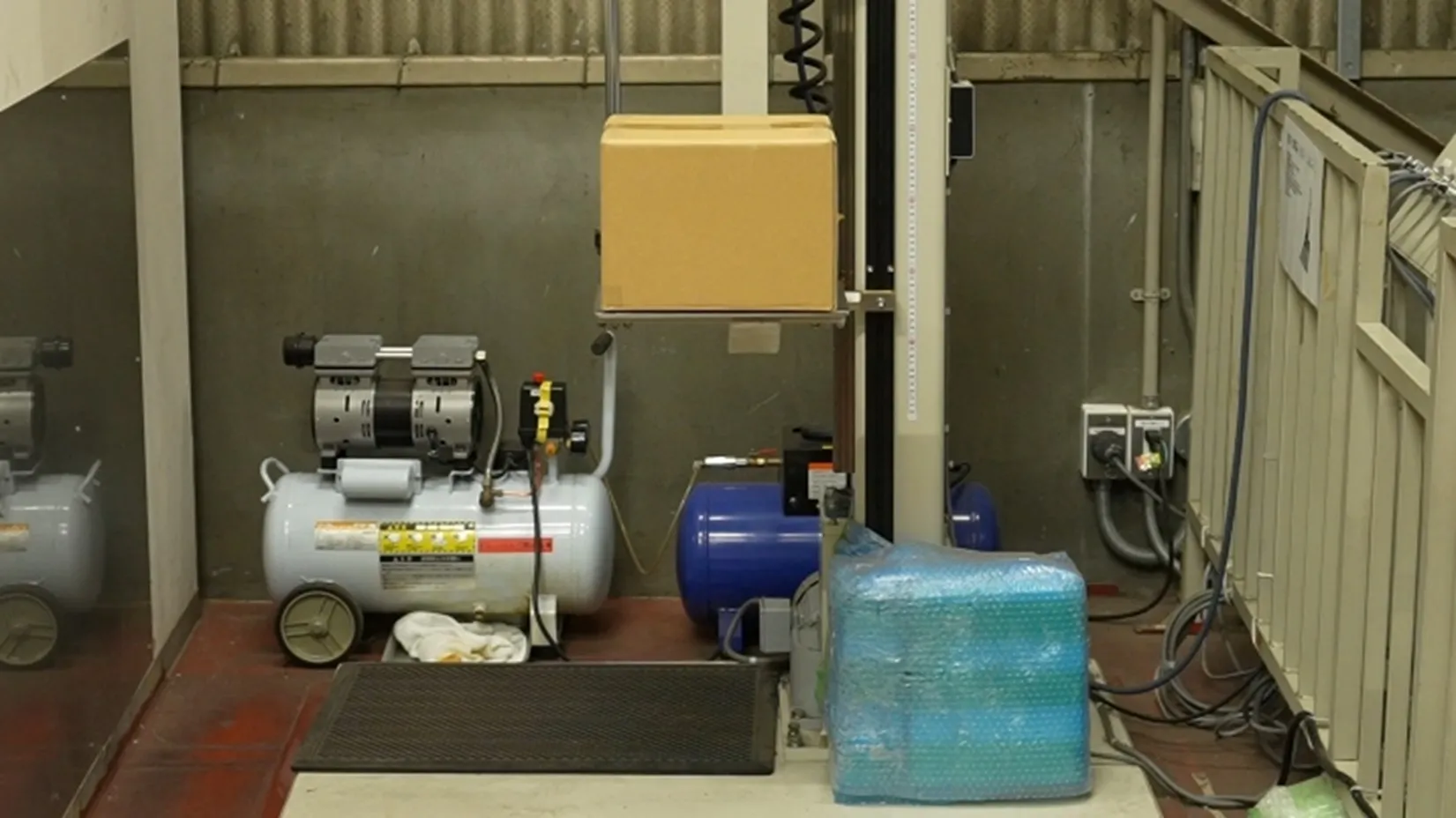

Toshiba Logistics traditionally relied heavily on design workflows of building and then testing physical prototypes and repeating the process until the results were acceptable. For logistics packaging, this meant countless iterations of drop tests, vibration tests, and impact assessments. Each round added time and expense, with costs running into millions of yen. In some cases—such as with one-of-a-kind or high-value items—destructive testing wasn’t an option. Another consideration was the growing pressure to reduce the use of plastic, which demanded new approaches to materials.

SBS Toshiba Logistics needed a solution that would enable them to design smarter and reduce repetitive cycles without sacrificing reliability.

Simulation in the Cloud

In 2024 the company expanded its long-standing use of Dassault Systèmes SOLIDWORKS® by adding Structural Mechanics Engineer to its workflow. Running in the cloud on the 3DEXPERIENCE® platform, the solution enabled SBS Toshiba Logistics to simulate nonlinear structural behaviors, including drops, contact, and dynamic vibration without building physical prototypes. As Chief Specialist Yukiyoshi Uchida explains, “If prototypes need to be made two or three times, it inevitably increases costs. Furthermore, for high-value items or those that must not break, we cannot perform destructive testing, which inevitably lengthens the design lead time. This had been a major issue for us. We chose to adopt cloud-enabled simulation to shorten lead times and reduce unnecessary costs.”

By combining SOLIDWORKS® with Structural Mechanics Engineer on the 3DEXPERIENCE platform, SBS Toshiba Logistics has reduced costly prototyping, accelerated development, and found new ways to innovate with sustainable packaging materials.

Related Resources

While we initially used Structural Mechanics Engineer simulation to conduct structural analysis of corrugated cardboard and foam materials, we have plans to also simulate the use of wood. This is an area that few competitors have yet to explore. By accumulating our own proprietary know-how and providing it to our customers, we are differentiating our company and believe we have reached a level at which this technology can be applied to our design work.

Cutting Costs, Gaining Insight

The impact of simulation was immediate. With Structural Mechanics Engineer, the team could validate packaging designs before building prototypes, dramatically reducing the number of design-prototype-test loops. Specialist Taichi Toda notes, “Since we introduced cloud-based simulation, we have been able to verify the validity of our designs through structural analysis and make improvements without waiting for testing, so we can dramatically reduce the number of design-prototype-test cycles.”

Beyond cost and time savings, simulation gives SBS Toshiba Logistics insight into packaging performance at a level that physical testing cannot match. For example, impact analyses of corrugated cardboard revealed 0.01- to 0.02-second micro-movements during a drop. Such details are impossible to capture with the naked eye. These insights improve design confidence and provide compelling visuals during customer reviews.

Differentiating the Business

SBS Toshiba Logistics is also using Structural Mechanics Engineer to explore new packaging materials. As plastics are being phased out, alternatives like corrugated cardboard and foam are gaining traction. Structural simulation helped the team calibrate these materials, understand their behavior under stress, and optimize their use in packaging designs. Toda notes, “While we initially used Structural Mechanics Engineer simulation to conduct structural analysis of corrugated cardboard and foam materials, we have plans to also simulate the use of wood. This is an area that few competitors have yet to explore.”

By building proprietary know-how in material simulation and sharing those insights with customers, SBS Toshiba Logistics is securing a competitive advantage. General Manager Noriyuki Kagami summarizes the company’s vision: “We aim to establish new technology as the engine for our company’s growth and to increase added value from the customer’s perspective.”

Moving Forward

For SBS Toshiba Logistics, the integration of Dassault Systèmes SOLIDWORKS with Structural Mechanics Engineer has transformed packaging design. What once required months of expensive prototype testing can now be validated virtually and with deeper insights into material performance. The result is faster, more sustainable, and more innovative solutions that not only meet customer needs but also set the company apart in a competitive logistics market.

Products:

- SOLIDWORKS Premium with Cloud Services

- SOLIDWORKS Standard

- 3DEXPERIENCE Platform Extended Storage

- 3DEXPERIENCE SIMULIA Structural Mechanics Engineer

- 3DEXPERIENCE Platform

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.