Vermeer Redefines Innovation in Heavy Machinery

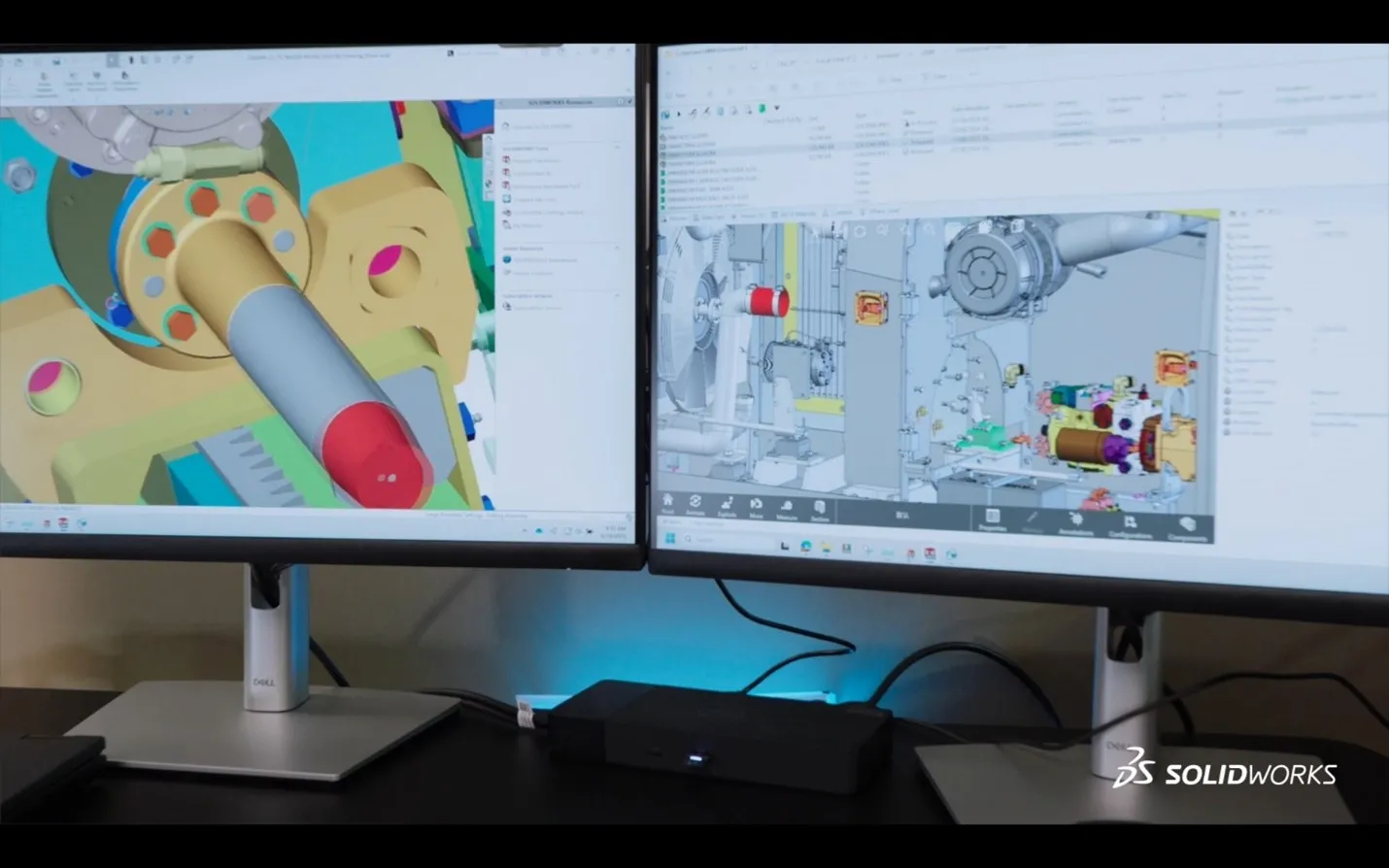

Global manufacturer of industrial and agricultural equipment streamlines design and expands business with SOLIDWORKS 3D CAD and the cloud-based 3DEXPERIENCE platform.

Challenge

Accelerate machinery development by streamlining and integrating design, manufacturing, purchasing, and documentation processes to expand product offerings and support increased throughput.

Solution

Implement SOLIDWORKS® Extended Portfolio to manufacture large-assembly industrial and agricultural equipment machinery means tackling complexity on all levels. Seamlessly integrate massive mechanical systems with high tolerances.

Results

- Automated development workflows

- Increased development and production throughput

- Shortened and formalized the engineering change process

- Manage every part within SOLIDWORKS

Developing, designing, and manufacturing large-assembly industrial and agricultural equipment machinery means tackling complexity on all fronts. Industrial equipment engineers must seamlessly integrate massive mechanical systems (steel frames and drivetrains), tight-tolerance hydraulics, sophisticated electronics, and complex software controls into a single machine, with each subsystem interfacing smoothly to deliver immense power and precise control. In addition, every system and component, from sensors to structural welds, must be built to take abuse in the field such as constant vibration and shock loads, extreme heat, pervasive dust and mud, and more. Overcoming these challenges requires disciplined engineering, advanced design tools, and a culture of continuous improvement. That commitment to precision and innovation has been at the core of Vermeer Corporation since the beginning.

Vermeer built its reputation on one guiding principle: There has to be a better way. From the round hay baler that revolutionized farming to horizontal directional drills that made underground fiber installation possible, the Iowa-based equipment manufacturer has consistently engineered machines to solve real-world problems. From its very first machine—a mechanical wagon hoist that made unloading corn faster and easier—to more than 100 models in production and a growing global footprint across Latin America, Europe, the Middle East, Africa, Asia, and Australasia, today Vermeer faces the challenges of efficiently designing complex machinery with thousands of components, managing ever-increasing regulatory burdens, and delivering reliable, innovative equipment solutions to customers worldwide.

Related Resources

We leverage SOLIDWORKS to design our medium drill, a very complex machine with a lot of hydraulics and electrical [components] that is used to install utility cables for phone lines, electrical lines, and fiber optics throughout the world.

To meet these demands, Vermeer relies heavily on Dassault Systèmes SOLIDWORKS® 3D CAD software and the 3DEXPERIENCE® platform, which enables the company to improve collaboration, accelerate design cycles, manage data, and maintain quality while keeping pace with company growth.

Engineering for Performance

The Vermeer product portfolio includes highly complex equipment such as horizontal directional drills, machines that integrate hydraulics, electronics, and control systems into assemblies that can easily exceed 10,000 parts.

"We leverage SOLIDWORKS to design our medium drill, a very complex machine with a lot of hydraulics and electrical [components] that is used to install utility cables for phone lines, electrical lines, and fiber optics throughout the world," explains Vermeer System Analyst Manager Greg Johnson.

The highly innovative medium drill has advanced features that assist operators in making precise decisions to avoid water or sewer lines during drilling. Vermeer leverages SOLIDWORKS in designing every aspect from the major structural components to the smallest intricate details of the machine. In fact, SOLIDWORKS is Vermeer’s sole platform for all mechanical CAD design work.

“One of the advantages of working with SOLIDWORKS is our ability to reuse components throughout many different [machine] models," Johnson continues. “And many of those components can be reused from one drill [machine] to another. Because SOLIDWORKS uses parametric modeling, engineers can resize an existing design for a different machine by simply updating the underlying geometry. When a component is updated in SOLIDWORKS, that change automatically propagates through every assembly in which the part is used, which saves significant time and reduces the risk of design errors.”

Unified Data and Collaboration with 3DEXPERIENCE

With Vermeer’s growth came a surge in product data and design complexity that traditional tools could no longer handle efficiently. Harold Sullivan, Vermeer Director of Product Lifecycle Management, describes how fragmented systems used to foster inefficiency: “We used 53 different tools to manage a project, with 20 different locations for storing information and 25 subprocesses tied to a single activity.”

Dassault Systèmes 3DEXPERIENCE platform was selected to unify processes and create a single source of truth for engineering and manufacturing data. By moving to a cloud-based system, Vermeer gained scalability and regular updates without the disruption of lengthy software upgrades. “[Upgrading SOLIDWORKS manually] took us about eight months. It required hundreds of man hours to accomplish that upgrade,” recalls Sullivan. “In that same time period, our 3DEXPERIENCE cloud platform was updated three times [automatically] with virtually no effort on our part.”

Beyond efficiency, 3DEXPERIENCE provided a framework for organizational discipline. Engineers now work under defined product-change controls, parts classification systems, and configuration management rules. Instead of creating duplicate parts, engineers can search attributes like fan size, blade count, or hub orientation to quickly find what they need. The result is fewer redundant parts, lower inventory costs, and more consistent designs across product lines.

By implementing 3DEXPERIENCE product lifecycle management, Vermeer established a foundation for global collaboration and standardized data management and enabled long-term scalability, all while keeping SOLIDWORKS at the core of its design process.

Designing Amid Myriad Challenges

Large-equipment operators often work long hours in high-stakes environments. A design tweak that reduces fatigue or improves visibility may save lives. Therefore, modern cabs are pressurized and climate-controlled for dust and noise reduction. They also have ergonomic seats, clear sightlines, and low-effort controls to reduce operator fatigue and help keep crews alert through long shifts. Logistics constraints further demand that many big machines are created with modular designs that disassemble into shippable sections for legal road transport and fast reassembly on site.

Vermeer Senior Machine Tool Engineer Scott Riddle noted that his team depends on key SOLIDWORKS features such as structural analysis and multi-configuration modeling to optimize designs. “We must maintain a certain max weight while considering weight distribution on the semi-trailer versus the tires,” he explains. Meeting shipping limits is never a nice-to-have with large machinery. Using SOLIDWORKS, the team precisely adjusts the machine’s center of gravity during the design phase to meet these constraints.

To avoid million-dollar mistakes, companies like Vermeer leverage advanced simulation and digital twin technology in designing large machinery. Long before a physical prototype is built, engineers create virtual models of the equipment they subject to simulated stress, loads, and usage scenarios. Catching a potential design flaw early in the digital phase can save enormous costs, as issues found during the concept/design phase in simulation are far cheaper to fix than problems discovered after manufacturing.

Effectively Managing Growth

Vermeer’s integration of SOLIDWORKS and its supporting platforms has delivered measurable results. Design cycles are faster thanks to parametric modeling and the ability to reuse components across multiple projects. Automated workflows now drive design reviews and engineering change management, which reduces errors and saves time.

Communication among engineering, manufacturing, and technical writing teams has improved, ensuring alignment throughout the product lifecycle. The company has also developed greater organizational discipline in managing product data, processes, and lifecycle management with 3DEXPERIENCE, which has created a more efficient and reliable development environment.

“We wanted a platform that worked on the cloud, then we wanted to be able to integrate different business units and be able to replicate those processes globally. The 3DEXPERIENCE platform provided the functionality we needed to grow as a company and to continue to be more efficient,” enthuses Johnson.

For Vermeer, SOLIDWORKS and the 3DEXPERIENCE platform are not simply product development tools, but the backbone of a broader digital transformation. They enable engineers to focus on solving real-world problems while having the ability to scale with the company’s growth ambitions.

Mark Cooper, VP of Product Quality and Reliability, emphasized that as Vermeer scaled, SOLIDWORKS enabled the team to work more efficiently while meeting growing design and performance demands. He concludes: “When I started, Vermeer was significantly smaller. SOLIDWORKS grew with us, giving us the tools to deliver what our customers and internal teams needed. It’s one of the key reasons we were able to take our next steps forward.”

Products:

- SOLIDWORKS Premium CAD

- SOLIDWORKS Simulation Premium

- SOLIDWORKS PDM

- SOLIDWORKS Composer

- 3DEXPERIENCE Platform

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.