Weland Builds Precision One Step at a Time

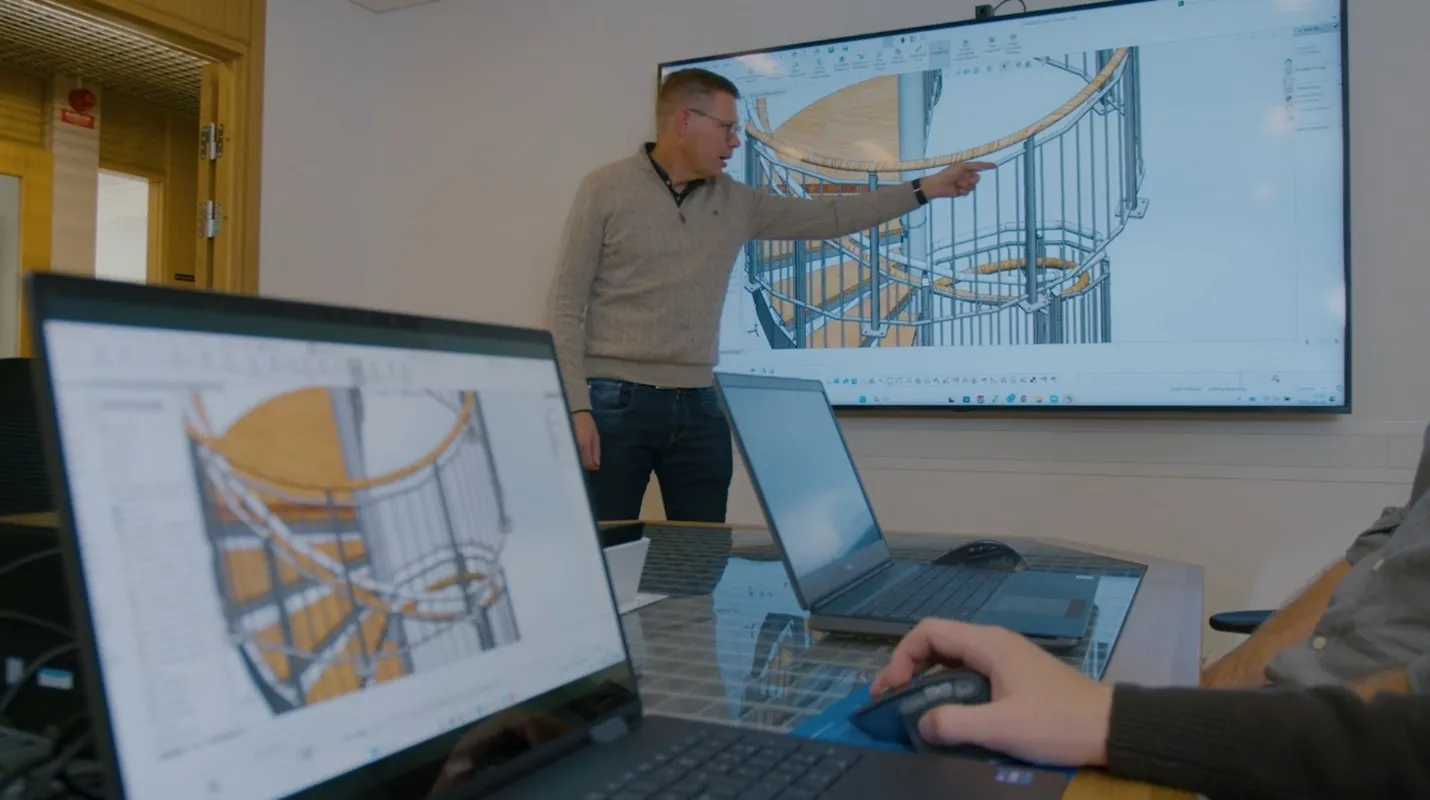

With SOLIDWORKS 3D Design, 3D Composer, and PDM, a steel products manufacturer strengthens quality, accelerates delivery, and expands engineering possibilities.

Challenge

Accelerate quality and reduce the cost of new products while incorporating new customer needs for customized products, and enable those customers to visualize their products before production.

Solution

Replacing old 2D CAD tools with SOLIDWORKS® 3D Design solutions to design and manufacture many different products at once, and offer customers an easy way to preview and approve final designs. Many product designs are stored and managed with SOLIDWORKS PDM Professional.

Results

- Allow innovation and the ability to create new concepts easily

- Create complex geometries

- Streamline the engineering design and change processes

- Manage every part within SOLIDWORKS

For more than 30 years, Weland AB has stood as one of Sweden’s leading manufacturers of steel staircases, gratings, and accessibility ramps. The family-run company supplies thousands of products each year to customers across Europe and beyond from its headquarters in and factory in Smålandsstenar.

Weland began in 1947 with two brothers-in-law producing just wing nuts from a small-scale workshop before greatly expanding over the decades. “We produced steel products such as staircases and accessibility ramps,” explains Design Engineer Vilgot Blohm. “Then we moved on to gratings. And we believe that gratings are the backbone of the company because we put them in a lot of our products.”

Instead of outsourcing major stages of production, Weland keeps those processes inside the company. The result is tighter control over quality, cost, and customization. It’s how they keep production predictable and ensure their products meet the structural and safety standards their customers expect. “We manufacture all our steel products under one roof, right here at Weland. We always have about 6,000 tons of raw material on hand,” explains Blohm. The company typically delivers around 40 spiral staircases each week.

Powering Innovative Stair Design

Like many established manufacturers, Weland once relied on 2D programs to produce drawings and customer documentation. But those systems limited visualization and slowed the design-to-production process. “Before we used SOLIDWORKS®, we used a 2D program, so we couldn't save 3D models or send them to our customers,” recalls Design Engineer Isak Hulander.

That all changed when the company introduced SOLIDWORKS into its workflow. “I first started using SOLIDWORKS in high school,” Blohm recalls. “And I've used it continuously ever since I started working at Weland. Learning SOLIDWORKS in school opened a lot of possibilities because a lot of companies are using it as their modeling program.”

Related Resources

SOLIDWORKS has helped us a lot with our customer drawings because customers can visualize how the staircase will look in real life.

Weland currently operates with about 40 SOLIDWORKS licenses but actual usage is far higher thanks to its floating license model, which offers licenses similar to borrowing a book from a library: The company owns a limited number of “copies” of SOLIDWORKS licenses, just like a library owns a limited number of books. Anyone can “check out” a license, but only if a copy is available. When an employee opens the software, it’s like checking out a book. When they close the software, they “return” it, and the next person can check it out. It is an efficient and effective way to give more people access to SOLIDWORKS without buying a license for every single user.

The software has become integral not only to the company’s daily design work but also to enabling its creative flair. Blohm’s favorite aspect of SOLIDWORKS is having the freedom to create virtually anything he imagines. Hulander shares that view, noting that SOLIDWORKS not only enables countless creative design possibilities but also makes the process remarkably intuitive and efficient.

Step by Step Innovation

The move to 3D has made it possible to model more complex geometries and streamline the design process. “A new sheet metal spiral staircase called JOS is one example of a really big solution we were able to make because we worked in 3D,” Hulander explains. “We couldn't have made the JOS staircase without the 3D program SOLIDWORKS. In addition, SOLIDWORKS PDM Professional provides the data control and design-reuse framework that lets our team easily pull from validated models instead of rebuilding components for every new project.”

Blohm emphasizes the value of designing in 3D for visualization: “SOLIDWORKS has helped us a lot with our customer drawings because customers can visualize how the staircase will look in real life.” Hulander adds, “We can send a 3D model (in STEP file format), and our customer can put it [our actual design] into their model to make sure everything fits perfectly.”

With its integrated use of SOLIDWORKS 3D CAD, SOLIDWORKS Composer, and SOLIDWORKS PDM Standard, Weland continues to streamline production, improve collaboration, and accelerate delivery all while maintaining the superb craftsmanship that defines Swedish engineering.

Products:

- SOLIDWORKS Premium CAD

- SOLIDWORKS PDM Professional

- SOLIDWORKS Composer

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.