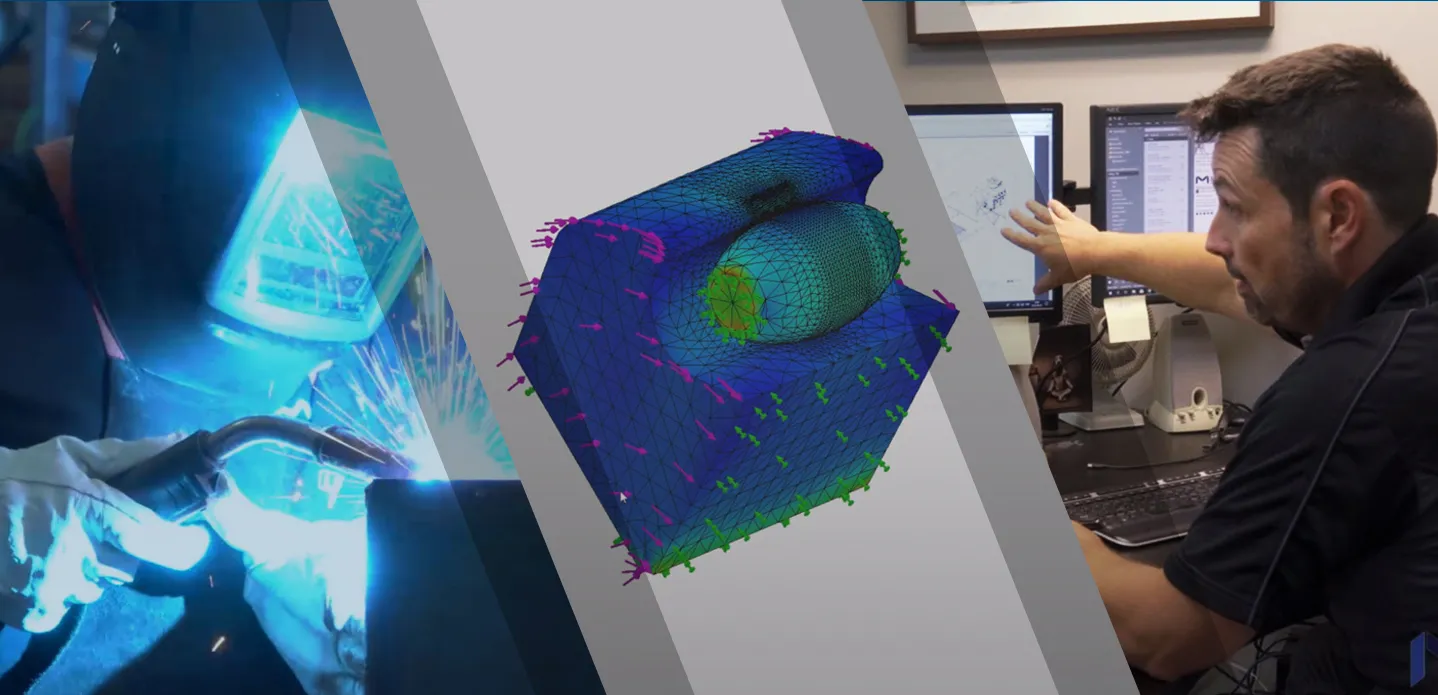

Innovation Begins with Integrated Solutions

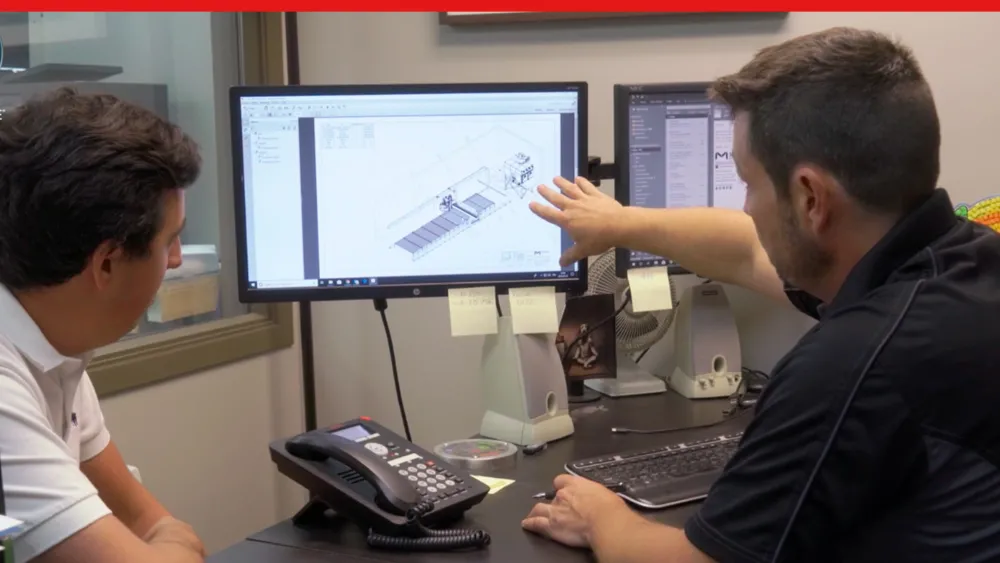

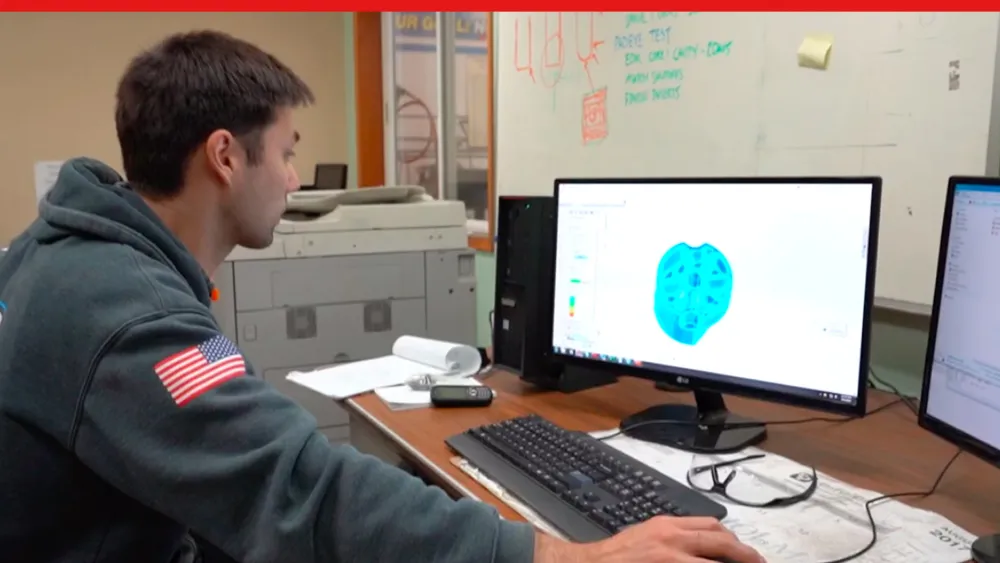

Today’s challenging industrial equipment (IE) design environment requires manufacturers to streamline processes. Upgrading from methods that rely on non-integrated, point solutions to concurrent, fully-integrated 3D design and manufacturing increases quality and adds to your bottom line.

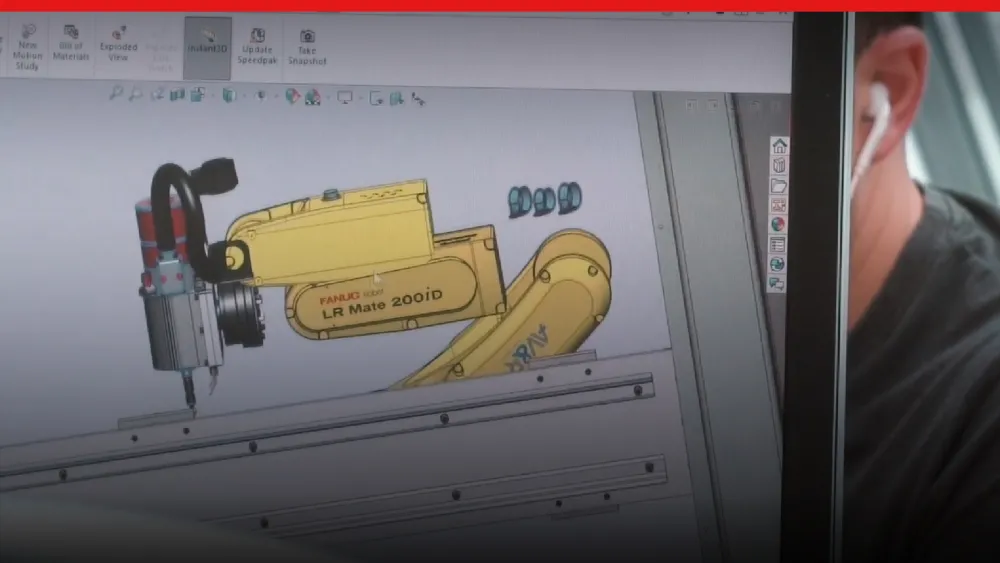

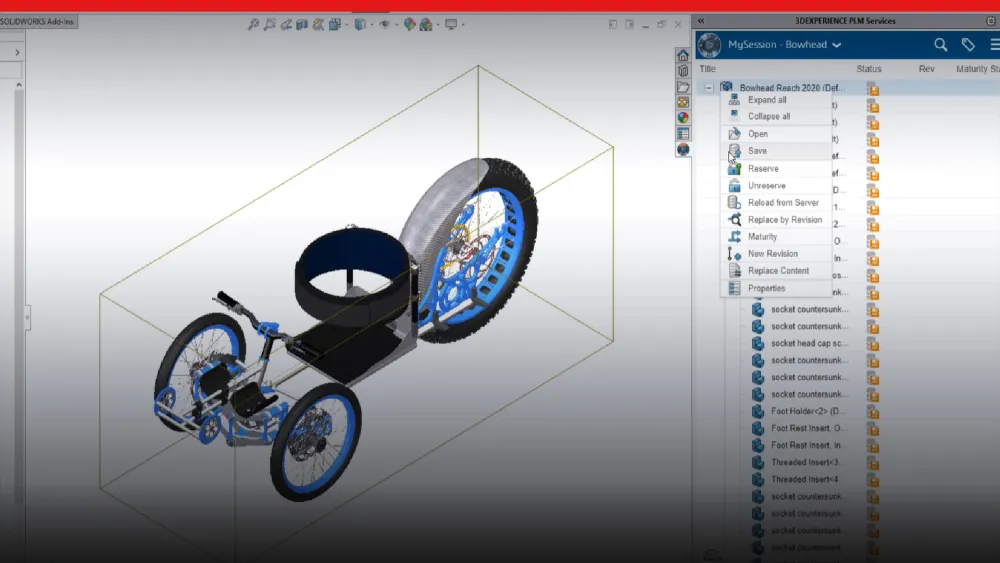

Watch the video to learn how IE companies succeed by using integrated CAD, simulation, management, ECAD, and manufacturing tools from SOLIDWORKS®.