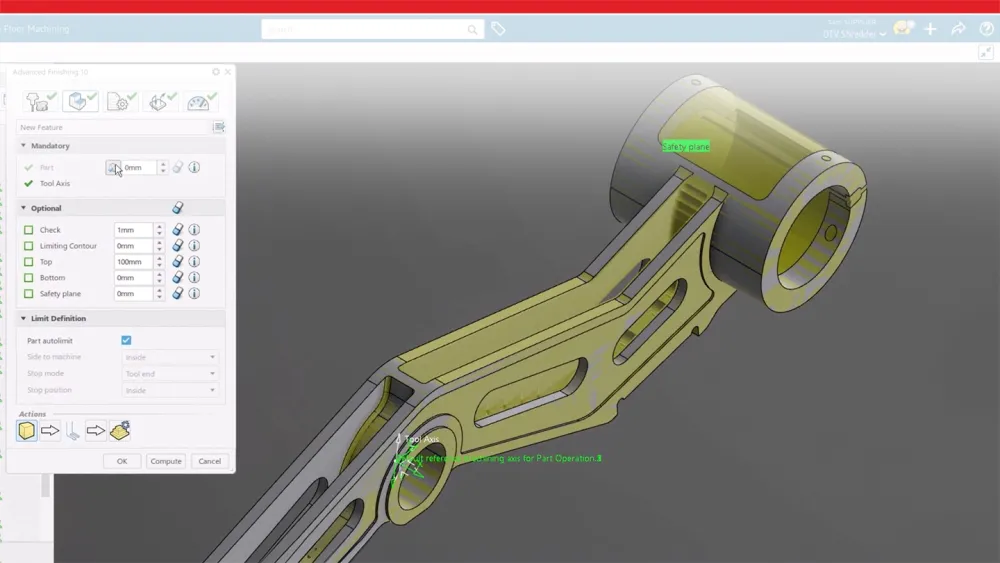

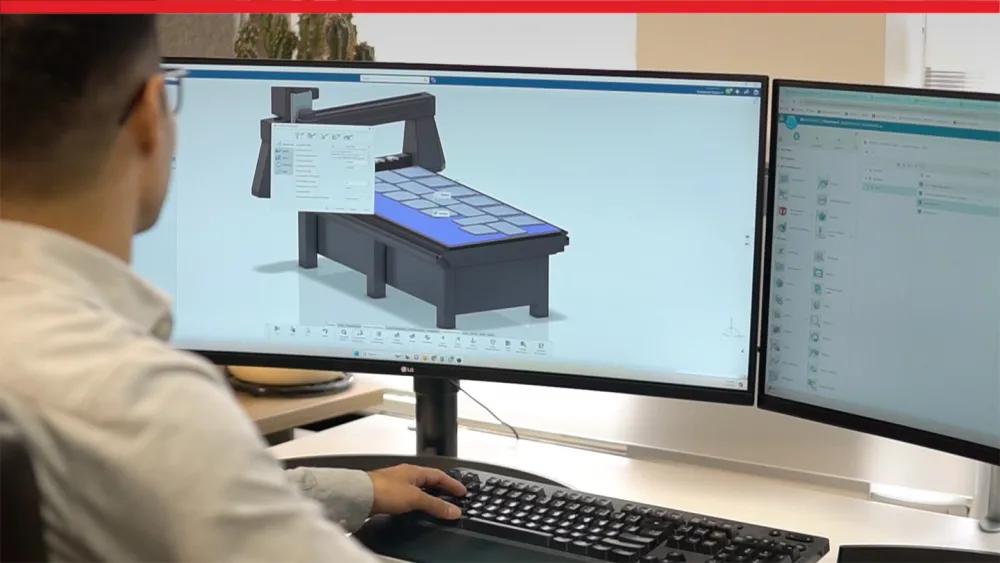

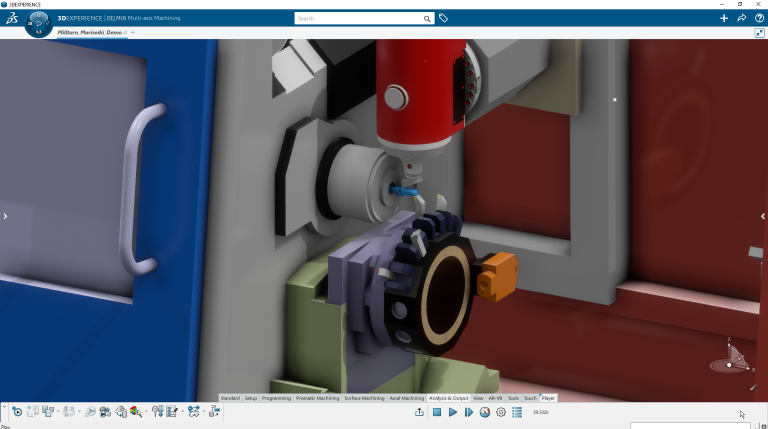

Bridge the Gap between Engineering and Manufacturing

Shop Floor Programmer provides a critical link between design and manufacturing, ensuring smoother workflows, reduced errors, cost savings and improved time to market. Benefits include:

- Manufacturability. Ensure that your original design intent is realized in production by enabling product designers to fully validate the manufacturability of proposed designs.

- Reduced lead times by streamlining entire workflows and enabling teams to quickly pivot based on design changes or customer requirements.

- Real-time insights. Fine-tuned toolpaths based on real-time insights, enabling custom adjustments for increasing efficiency, reducing cycle times, optimizing material usage and improving tool longevity.

- Scalability. Standardized processes can be easily replicated across different manufacturing lines, enabling companies to expand production without sacrificing quality or consistency.