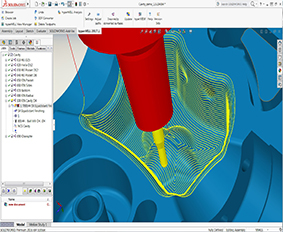

hyperMILL -the integrated CAM solution for SolidWorks - allows the user to turn CAD designs into NC code for machining without having to leave the familiar program environment. Integrated processes with universal data models guarantee security and transparency in the production process. Familiar user interfaces simplify operation and increase user acceptance. These are the reasons why OPEN MIND Technologies AG has long been providing integration with leading CAD systems. hyperMILL for SolidWorks offers 2D, 3D, HSC, and 5-axis machining strategies and a mill turn module - and all that under one user interface. Intelligent machining strategies reduce programming and machining time, thereby cutting production costs and shortening the 'time-to-market.' This CAM solution's greatly enhanced feature technology provides numerous options for standardizing and automating the programming of recurring and similar part geometry. Machining strategies and tools can be combined as macros and stored in a graphical database, from which they can be retrieved at any time. With the collision checking and avoidance features, the programming of 5-axis tasks has become as easy as 3D programming. In 5-axis simultaneous machining, the software calculates the tool positions automatically. All the user needs to enter is a preference angle. The OPEN MIND CAM Utilities support the user from the CAM to the NC program. Features for reliably checking the CAM programs users create and the ability to quickly and easily alter tool paths -- even during the final phase -- are among some of the helpful tools provided by the OPEN MIND CAM Utilities.