Why ERP is Essential for Growing Small and Mid-Sized Manufacturing Companies

Boost Efficiency and Scale Smarter: How a manufacturing ERP solution can provide the end-to-end visibility and control a company needs to grow successfully and profitably

As a manufacturing company grows in scope, complexity, and revenue, it reaches a point where its basic accounting software and/or multiple spreadsheets used to track production and inventory become more of a burden than a solution.

Quickbooks, spreadsheets, and siloed functions applications are common in young and small manufacturing companies. However, there is a limit to how far these stand-alone applications can take them.

In the words of a DELMIAWorks customer, “We can’t continue to operate this way if we want to continue to grow.”

Unlocking Growth for Manufacturers: The Power of Technology

In the manufacturing world, the road to growth is often lined with internal and external obstacles. Economic uncertainties, labor shortages, emerging competitors, and production constraints can be daunting challenges. Yet, a select group of manufacturers seem to defy these odds and continue their upward trajectory. How do they do it? And how can you join their ranks, especially if you are a small- or mid-size manufacturer?

The answers are in a recent survey conducted by The MPI Group, an independent global research firm. The report sheds light on the strategies employed by manufacturers to achieve new performance targets that support their growth initiatives. The key lies in their strategic use of technology that allows them to:

- Bring new products to market faster

- Expand sale opportunities in both new and existing markets

- Boost shop floor capacity and labor productivity

- Enhance production quality and customer satisfaction

Download The 3DS Technology Barometer — ERP report and delve into the details. Discover why some SMMs outperforming their competition and how you can be one of them.

“Stem-to-Stern" Visibility that Helps Manage Growth and Profitability

Successfully and profitably managing growth across multiple facilities can be challenging for many manufacturers. Mid-size manufacturing companies looking to scale operations and quickly adapt when new divisions open should take a lesson from Kennerly-Spratling.

The "stem-to-stern" system provides the visibility and functionality needed to:

- Support the spin-off of new divisions

- Track cost changes as they happen

- Monitor plant performance at both macro and micro levels

- Enhancing cross-department collaboration and decision-making

- Quickly onboard employees

Manufacturing Technology Investments that can Position your Company for Success

There’s no question that the business disruptions and challenges faced today will have a lasting impact on the future of manufacturing. Manufacturing companies face greater complexity in the wake of rapid shifts in skilled labor availability, customer demands, supply chains, and material costs. Good data and facts are essential to navigate successfully through these challenges.

Investing in the right manufacturing technology can provide the accurate data you need to:

- Make precise and timely business decisions

- Control costs

- Optimize resource utilization

- Quickly adapt to changes in demand

- Improve processes

DOWNLOAD THE WHITEPAPER to learn more about the manufacturing technology investments that can have the most significant impact on your operations and position your company for success.

Lessons Learned: How to Accelerate and Sustain Manufacturing Growth

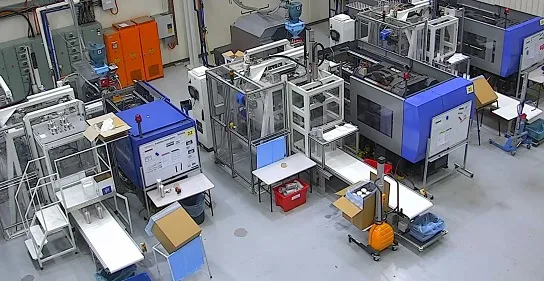

In a dynamic manufacturing industry, adaptability is crucial for success. To maintain growth and profitability, manufacturing companies need the transformative power of automation tools to manage their growing operations efficiently.

Gamsee Industries is a noteworthy example of how automation can help increase agility, control costs, and quickly scale operations.

“The automation and information that DELMIAWorks Manufacturing ERP solution provides has improved our ability to handle even the most complex molds and automate the production of family molds. We’re saving time and money, which helps us maintain and sustain our rapid growth trajectory.”

Read how Gamsee Industries has harnessed the full potential of DELMIAWorks to achieve these remarkable results:

- Quadrupled business over the past five years

- Improved margins and profitability

- Enhanced collaboration and decision-making

- Streamlined workflows

- Maximized resource utilization

Overcome Uncertainty to Gain Control of Your Business and Manufacturing Processes

"There is no normality to business anymore. You must be on your toes now more than ever before, and you need to make quick decisions to survive. Good data and facts are key to maneuvering during these times."

~ CFO, THE SISLERMANUFACTURING GROUP

Uncertainty has become a new norm for manufacturing companies. Don't expect it to go away. With so much uncertainty, gaining and maintaining control of your manufacturing operations may seem elusive, and yet, there is a proven approach. In short, visibility.

End-to-end visibility is the foundation of control. Peter Drucker said, "You can't manage what you don't measure."

Digital technology, specifically today's manufacturing-centric ERP, allows you to gain visibility of operational data so you can measure and analyze past performance to better predict and manage future scenarios.

It helps you stay "on your toes" and be agile to make decisions that have the most significant impact on your business, better and faster.

DOWNLOAD THE WHITEPAPER to learn how today's manufacturing-centric ERP solutions can help you gain control of your manufacturing environment and ensure that uncertainty doesn't restrict your growth

DELMIAWorks ERP Software Solution Related Products

Have questions about DELMIAWorks Manufacturing ERP Solutions?

DELMIAWorks solutions solve your manufacturing challenges by connecting the entire design to manufacture process.