What is Product Change Management and Why Should You Care?

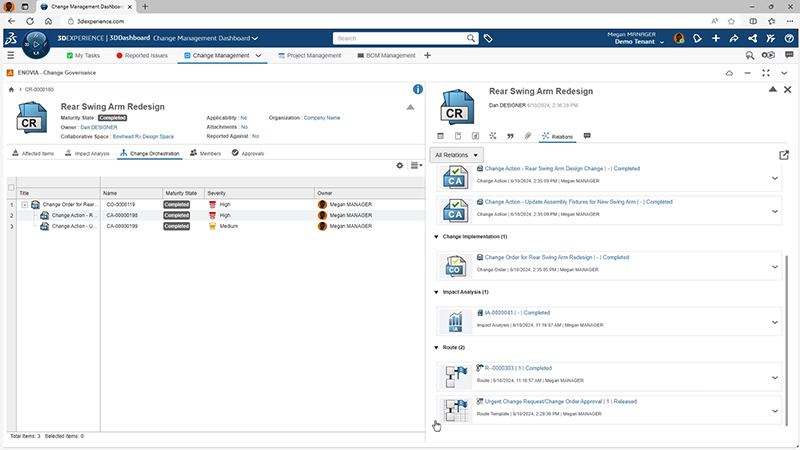

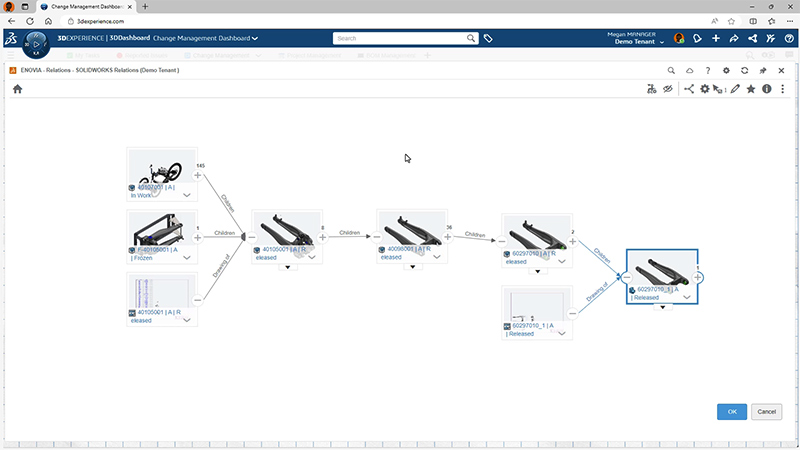

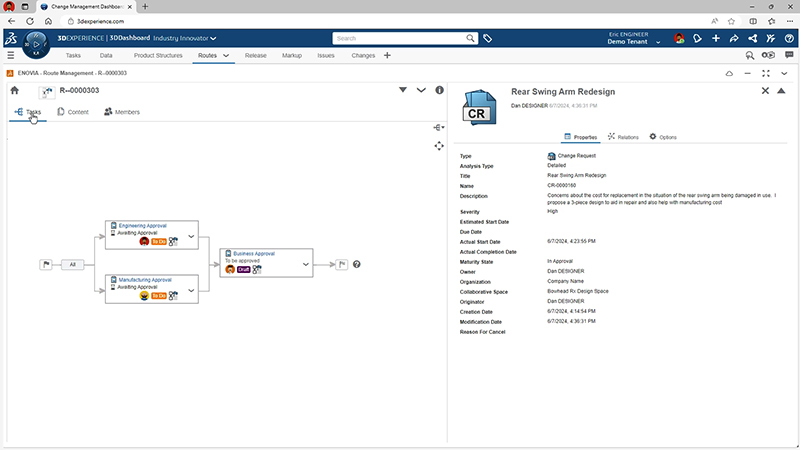

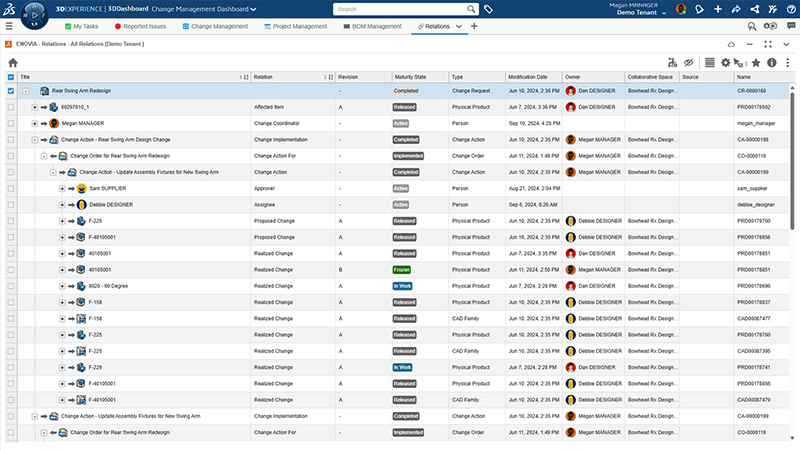

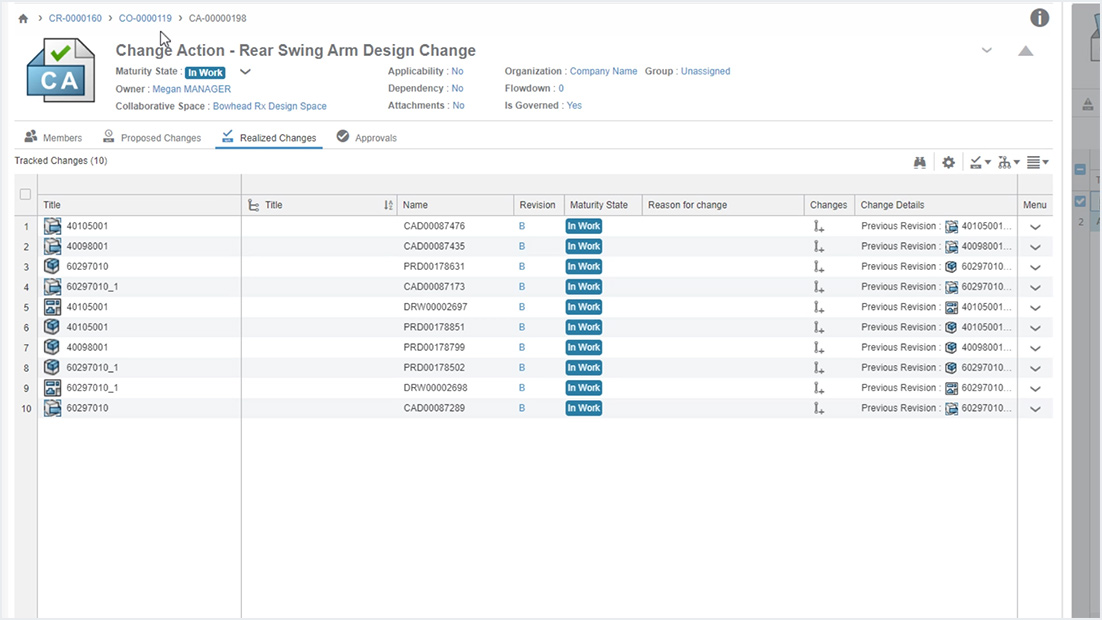

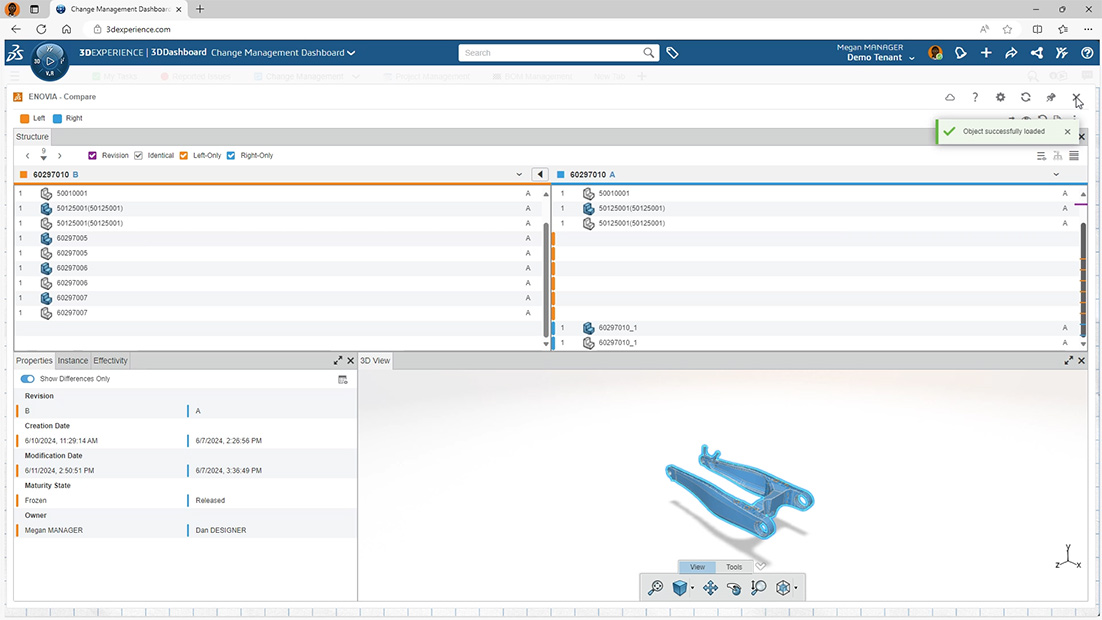

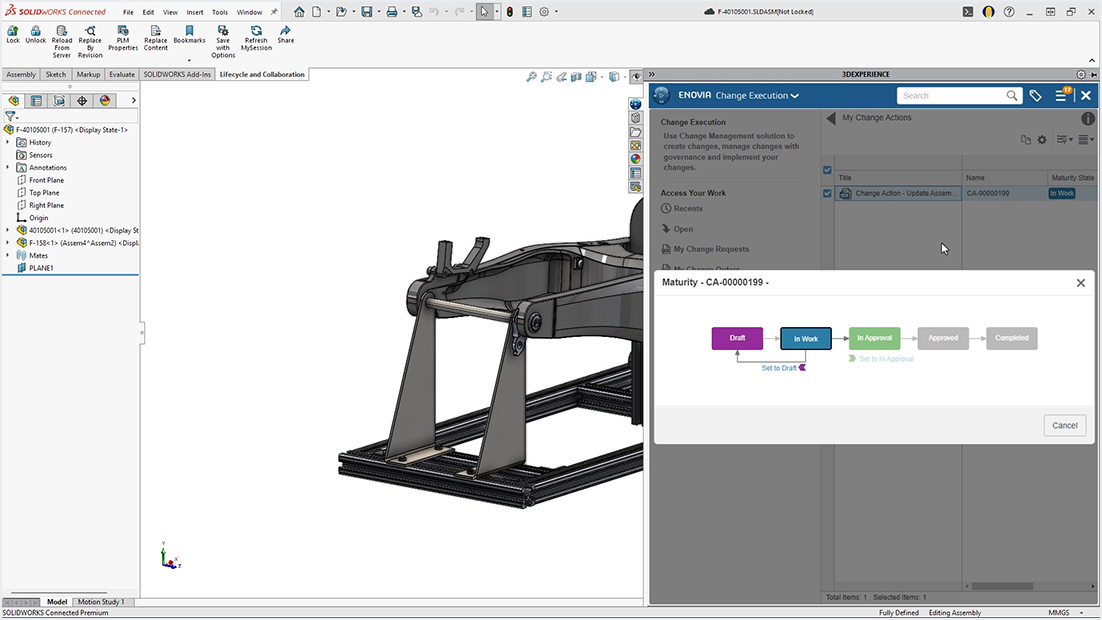

Product Change Management is a structured approach to handling modifications in product design, engineering documentation, or manufacturing processes. It ensures that changes are implemented efficiently, which helps to reduce risks, maintain compliance, and improve overall product quality. Any product revision follows a defined process to justify the modification, track its implementation, and document its impact.

Organizations do not modify a product without a valid reason. Changes typically stem from product improvements, field feedback, customer requirements, or issues discovered during prototyping. Without a proper system, teams risk losing traceability while making costly errors that create corresponding issues downstream.