Unified Design and Manufacturing: How BOM Management Improves Efficiency

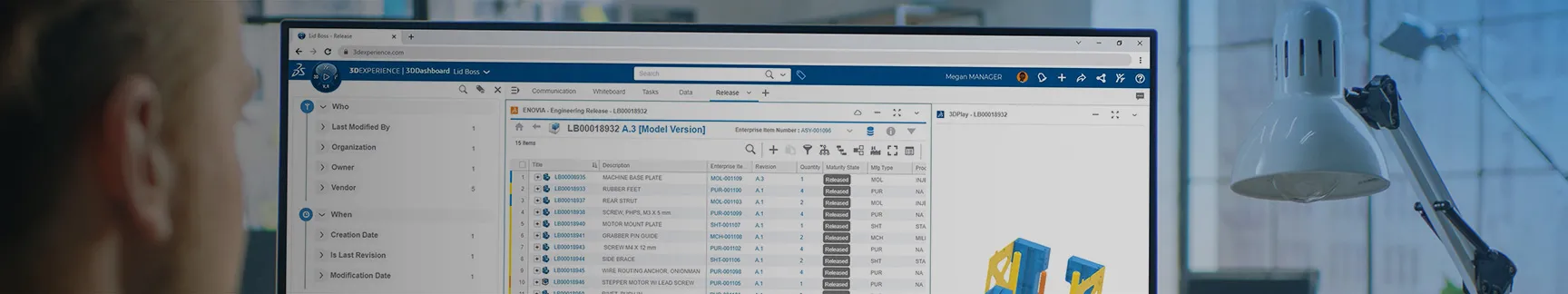

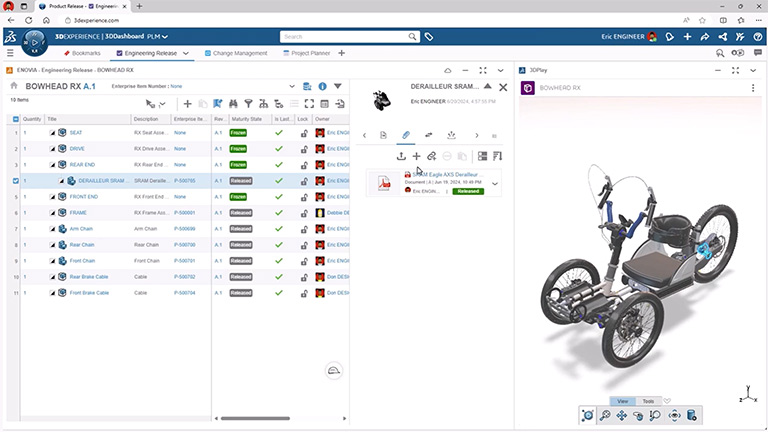

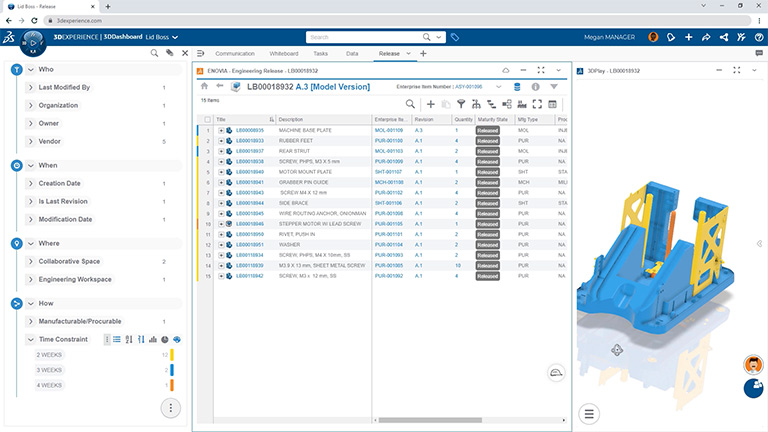

A unified design and manufacturing process emphasizes seamless collaboration among various teams, leveraging tools like the cloud-based 3DEXPERIENCE platform to centralize information and access to it. A centralized BOM is a key enabler of this approach, allowing all departments—from design to production—to work from the same set of data. This minimizes errors and fosters efficiency while maintaining adaptability throughout the process.

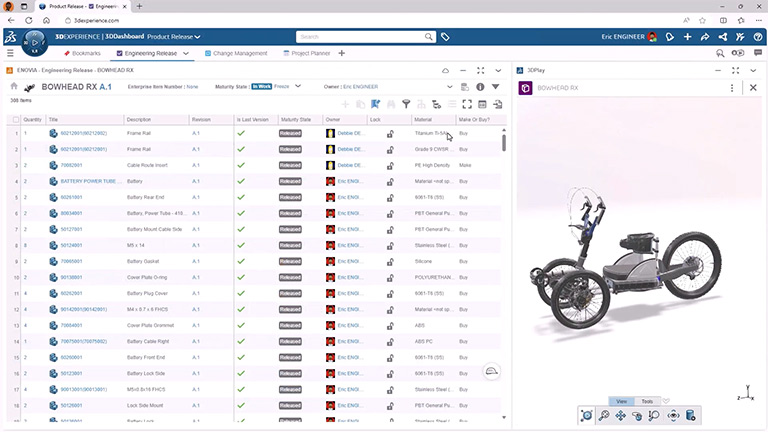

Here are a few examples of what a unified design and manufacturing process that leverages a centralized BOM might look like across various teams:

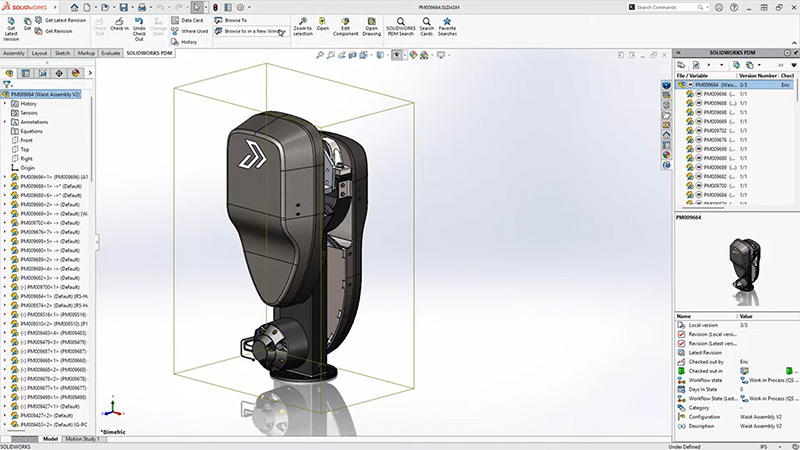

- Mechanical Engineering – A centralized BOM includes not only the mechanical parts (e.g., shafts, casings) but also integrates updates from the other teams to ensure compatibility with electronic housings or software interfaces. For example, the design of a motor casing must consider cooling vents for electronic components specified by the electronics team.

- Electrical Engineering – Electrical wiring diagrams are integrated into the centralized BOM, ensuring alignment with the mechanical team’s designs for routing and the electronics team’s PCB layouts. For instance, the BOM might highlight specific wire types or connectors that require precise routing through mechanical enclosures.

- Software Engineering – Software requirements, such as memory allocation or processing power, are documented in the unified BOM alongside hardware specifications. This ensures the electronics and electrical teams select microcontrollers or processors that can handle the software’s performance needs.

Real-time updates and shared access to product data enable smoother transitions from design through manufacturing. Plus, the digital BOM eliminates the need for manual updates, reducing errors and inconsistencies. Therefore, manufacturers can quickly adjust to changes in customer needs or supply chain issues without delaying production.

BOM accuracy is critical in product development because in addition to its use in manufacturing, BOMs are also utilized in design, engineering, procurement, supply chain, service, maintenance, and other departments. Everyone on the same page with the latest and most accurate information facilitates better cost estimation, materials planning, inventory management, and more.