What is the difference between PDM and PLM?

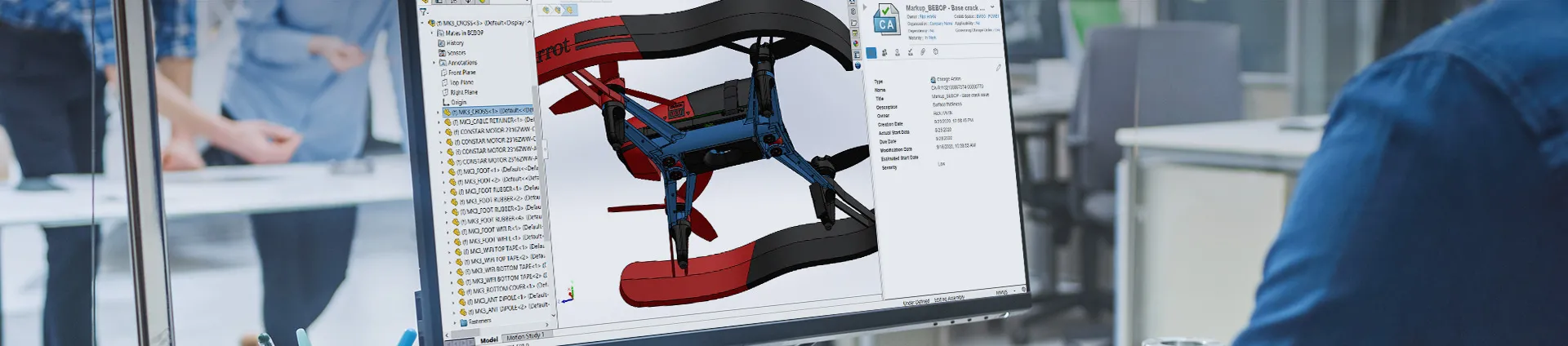

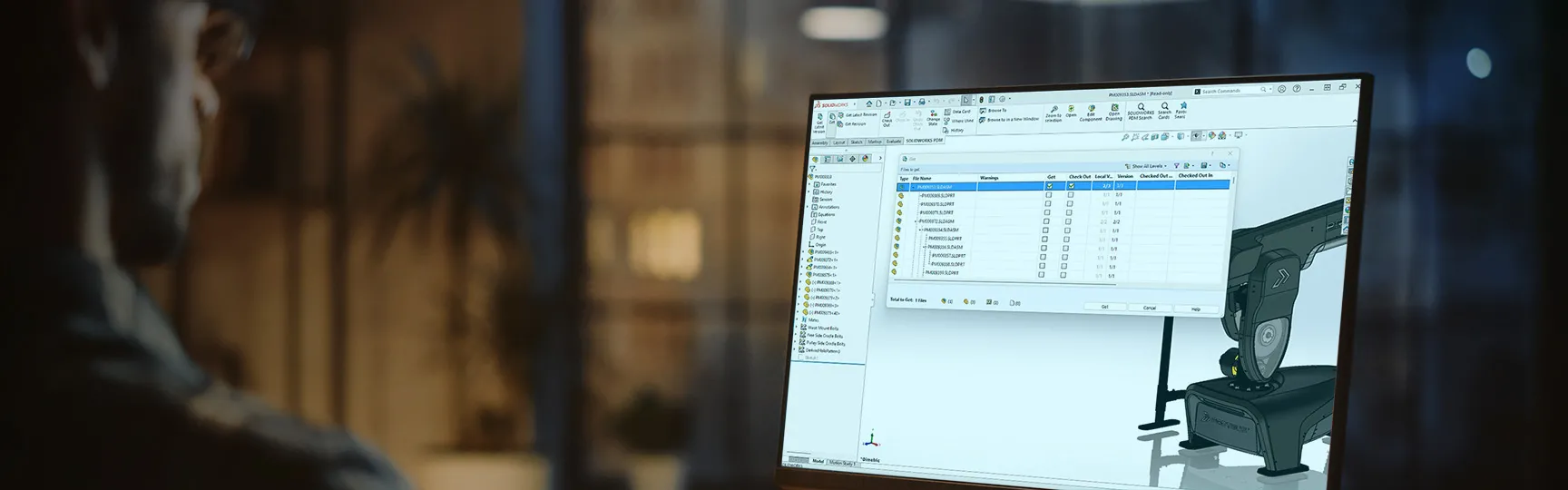

Without a robust data management system, managing product development files can be challenging, even for small to midsized companies. Misplaced files, overwrites, or poorly executed product releases waste time and result in countless costly issues.

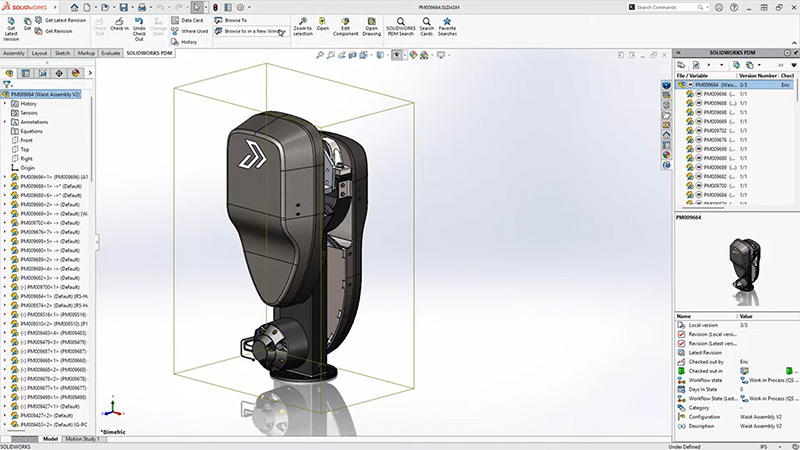

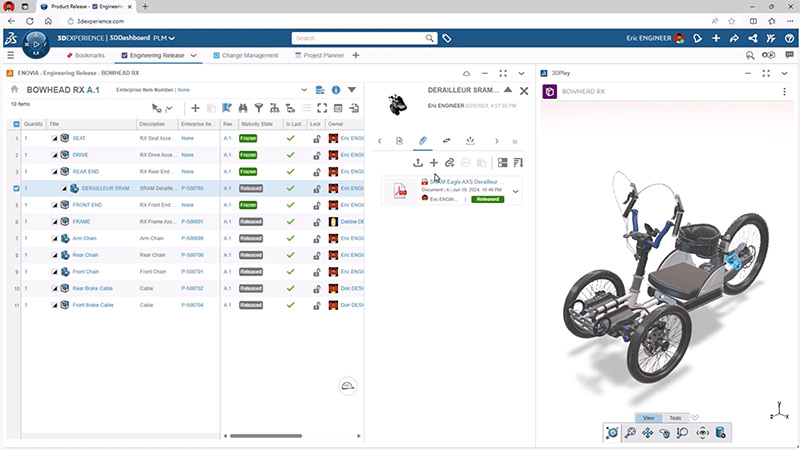

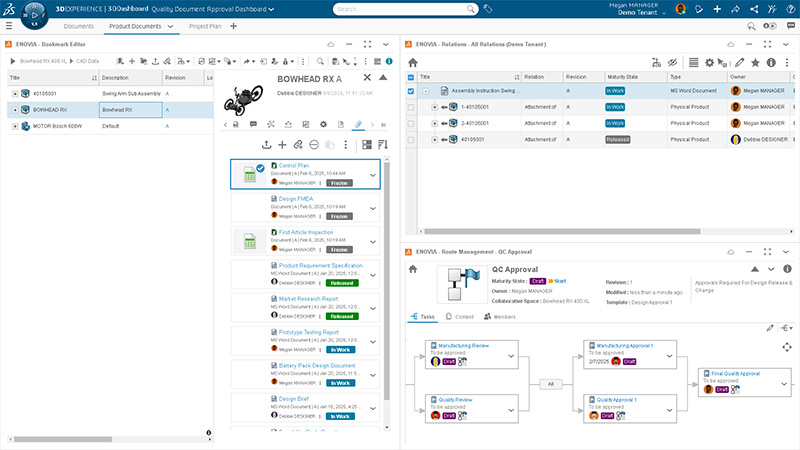

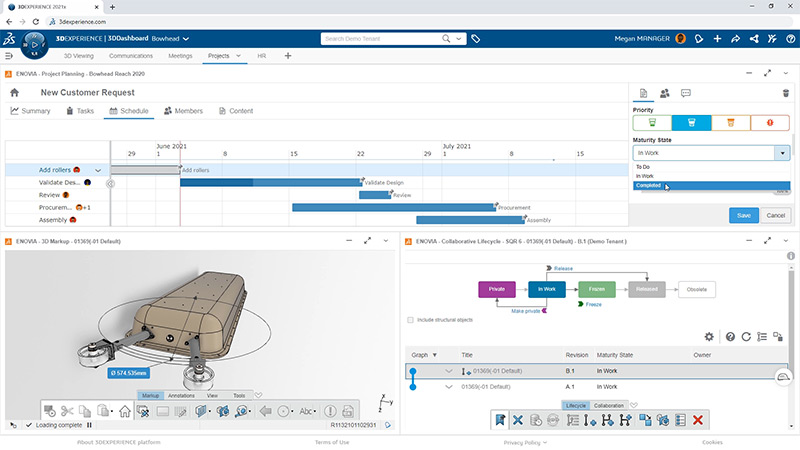

Effective file management is an essential feature of top-performing companies. The terms product data management (PDM) and product lifecycle management (PLM) are frequently tossed around, often interchangeably, though PDM and PLM systems serve distinct purposes.

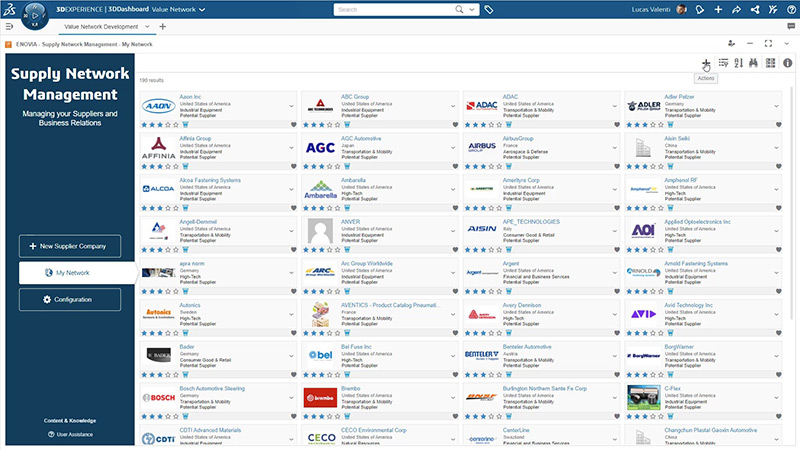

However, the relationship between them is mutually beneficial. Both systems are rooted in managing product-related data, and technically speaking, PDM is a subset of PLM. Each of them improves efficiency and productivity while streamlining processes. The relationship is especially effective when you add the flexibility of a cloud-based platform to the data management mix.