Since the early days of science fiction, robots have suffered under a stigma of intimidation and dread created by such indelible pop culture images as the ominous red eye of HAL 9000 and the skull-grinning menace of The Terminator.

Yet once you step away from science fiction and enter the real world, the potential for leveraging robotic technology to help people is huge. Robots can serve as helpers, companions, and friends. They can fulfill unique functions in educational settings. However, in order for people to overcome the entertainmentdriven stigma, robots must be cute, nonintimidating, and fun. They must also emulate humans in appearance and behavior.

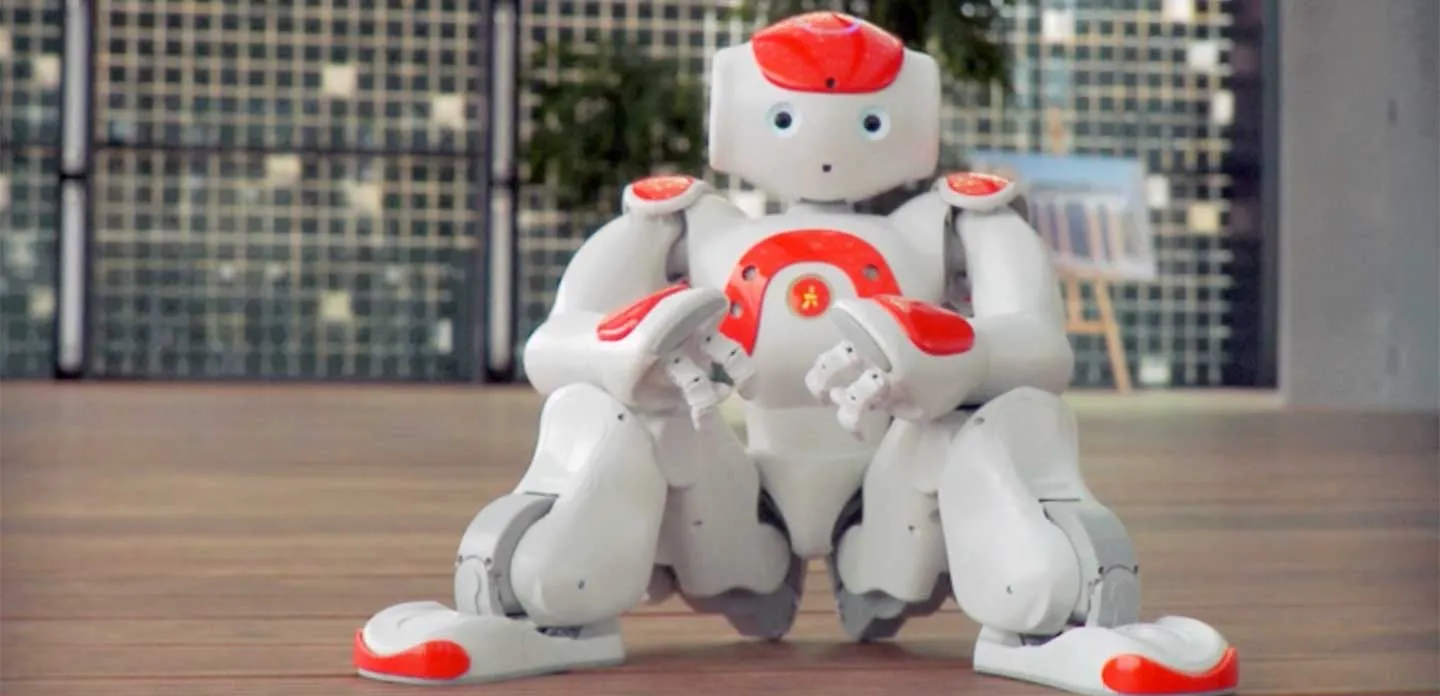

Humanizing and commercializing robots is the mission of Aldebaran Robotics. The French robot manufacturer’s introduction of the NAO® robot—the most advanced humanoid robot to date—represents a quantum leap forward in robot technology. Developing the NAO robot required the vision of Aldebaran’s founder, the talents of the company’s staff, and access to an integrated 3D development environment.

According to Founder/CEO Bruno Maisonnier, Aldebaran chose SOLIDWORKS software for design, surfacing, simulation, plastic injection molding analysis, product data management (PDM), and visualization because the intuitive, integrated design and engineering platform provides the company with the tools it needs to transform Maisonnier’s vision for humanoid robots into actual products. “Because our robots will help people, they must be useful and cool,” Maisonnier stresses. “To transfer the ideas in our minds into actual robots, we need a powerful 3D solution like SOLIDWORKS.”

Aldebaran utilized SOLIDWORKS Premium design, SOLIDWORKS Simulation Premium analysis, SOLIDWORKS Plastics injection molding analysis, and SOLIDWORKS Enterprise PDM product data management software in the development of the NAO robot.

SURFACING TOOLS HELP MAKE THE ROBOT MORE HUMAN

With SOLIDWORKS design tools, Aldebaran successfully achieved an important milestone designing the most humanlike robot ever created. Using tactile sensors, cameras, speakers, LEDs, and a microphone, the NAO robot can perceive and communicate with its environment, and learn through interaction with its owner. The robot’s movements are quiet, smooth, and humanlike; and its size and innocuous presence exude calm, friendliness, and comfort.

“The robot’s exterior shape had to be nonaggressive and aesthetically pleasing,” explains R&D Mechatronics Manager Vincent Clerc. “Our designers use SOLIDWORKS surfacing tools to create the smooth, elegant shape of the robot’s exterior, and interference detection capabilities to make sure that internal components fit properly. The SOLIDWORKS Enterprise PDM system allows our designers to focus on innovation while the PDM system takes care of the structure of the project.”

“NAO has 1,400 parts—as many parts as you will find in a small car,” adds Mechanics & Design Engineer Fabien Munier. “Fitting all these parts within a restricted space—NAO is only 60 centimeters tall—is challenging. SOLIDWORKS helps us do that by enabling us to simulate the performance and check for collisions on every component, ensuring that they fit and function as designed.”