Alexander Smith creates custom and mass-produced furniture pieces that bear his unique aesthetic imprint. With over a decade of experience in the design and management of residential, office, contract, custom, and retail furniture projects, Smith founded AS3D Design Ltd. in 2009 to provide product development services to the broader furniture market. Splitting time between the United Kingdom, France, and the United States, AS3D Design services clients and works with partners on both sides of the Atlantic Ocean from its Paris design studio. AS3D Design’s success stems from Smith’s particular strengths, including a focus on simple, clean designs; a depth of technical expertise; a wealth of knowledge of production processes; and important relationships with a range of quality manufacturers. In addition to his concentration on creativity, Smith takes pride in his ability to efficiently see a product design all the way through from initial consultation to production. In establishing AS3D Design, Smith realized that he needed a robust 3D development platform to support design and manufacturing, and a powerful 3D photorealistic rendering tool for showing and communicating design concepts to clients. Smith had used a variety of 2D and 3D CAD packages throughout his career. However, when it came time to purchase a 3D development environment to support his design consultancy, Smith chose SOLIDWORKS software. “I had used SOLIDWORKS in a previous company, and it just fit perfectly with our workflow,” Smith recalls. “I’d found SOLIDWORKS to be easier to work with than other packages which I had tried as a student and in previous professional roles. SOLIDWORKS gives me everything that I need for developing 3D geometry, from creative sketch design to general engineering and parametric design through documenting production drawings and BOM [bill of materials] generation. I always say, ‘It’s like a language. I speak SOLIDWORKS, and the great thing is that many of my factories and suppliers do too.’”

SUPPORTING A LEAN DESIGN APPROACH

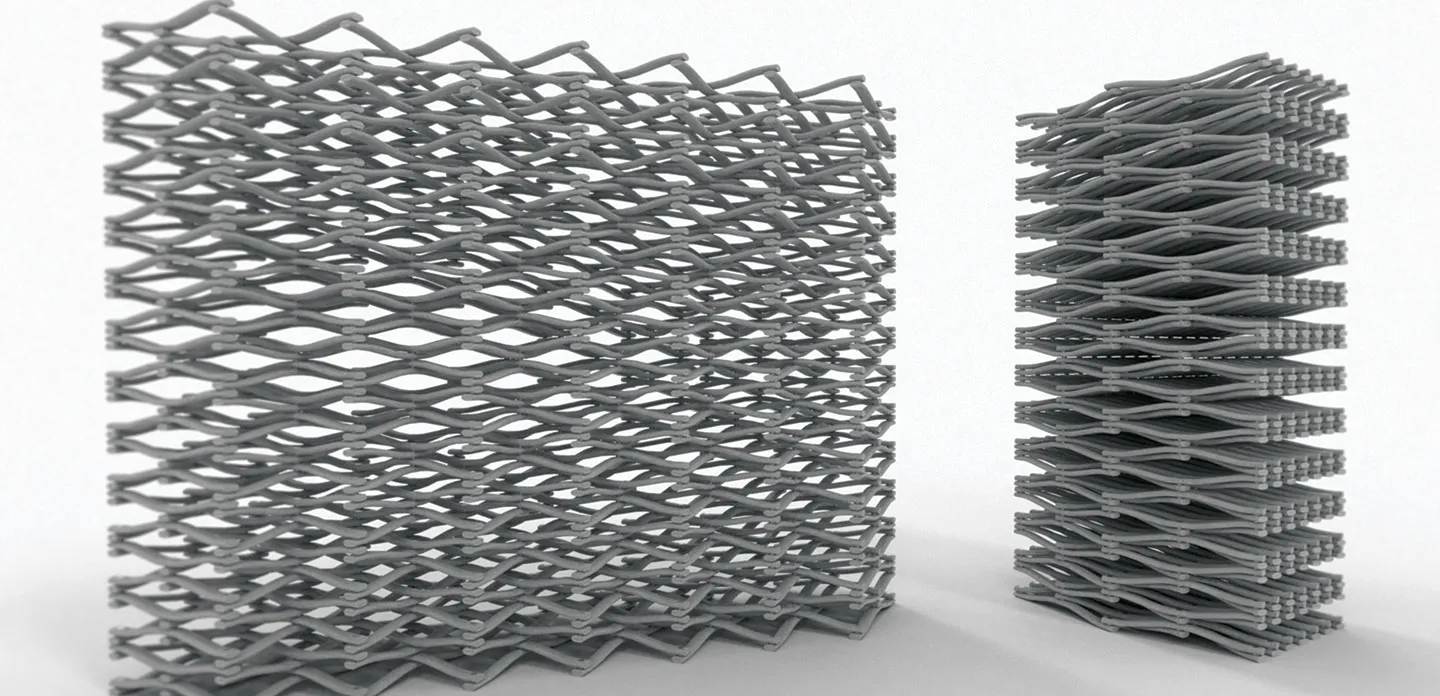

Although SOLIDWORKS design software provided AS3D Design with the capabilities needed to efficiently create compelling furniture designs, the consultancy also needed a fast, highquality rendering solution for presenting and communicating new furniture concepts to clients and manufacturing partners. “I adhere to a lean development philosophy, which benefits both my business and my clients,” Smith explains. “In order to maintain a lean design approach, I need a 3D rendering solution that generates the highest quality in the least amount of time. I found the perfect solution in SOLIDWORKS Visualize software,” Smith continues. “Because SOLIDWORKS Visualize software is part of the SOLIDWORKS family of products, it enables me to output high-quality renders in the shortest period of time, which gives me a real competitive edge. “I’m not wasting any time reimporting models, reapplying textures, remapping, and lighting every time there is a design change, which is critically important, particularly when you are working with wood because as far as texturing is concerned, it’s one of the most difficult materials to manipulate with realistic results.”