Using Solidworks Provides Quick Benefits

Initially, ALKA Group manufactured nailing machines, which had previously been imported into the country. With other applications, the design process typically required six to seven months. However, using SOLIDWORKS reduced the design timeline by 50 percent. Within just three months, the 3D design had been completed and the project came to life.

While the nailing machine project was in development, SOLIDWORKS was used to create drawings for all the parts and details, such as sheet expansion. Using the Big Picture feature of SOLIDWORKS to display the entire manufacturing process, the R&D department was able to both save time and increase machine production by an incredible factor of 15.

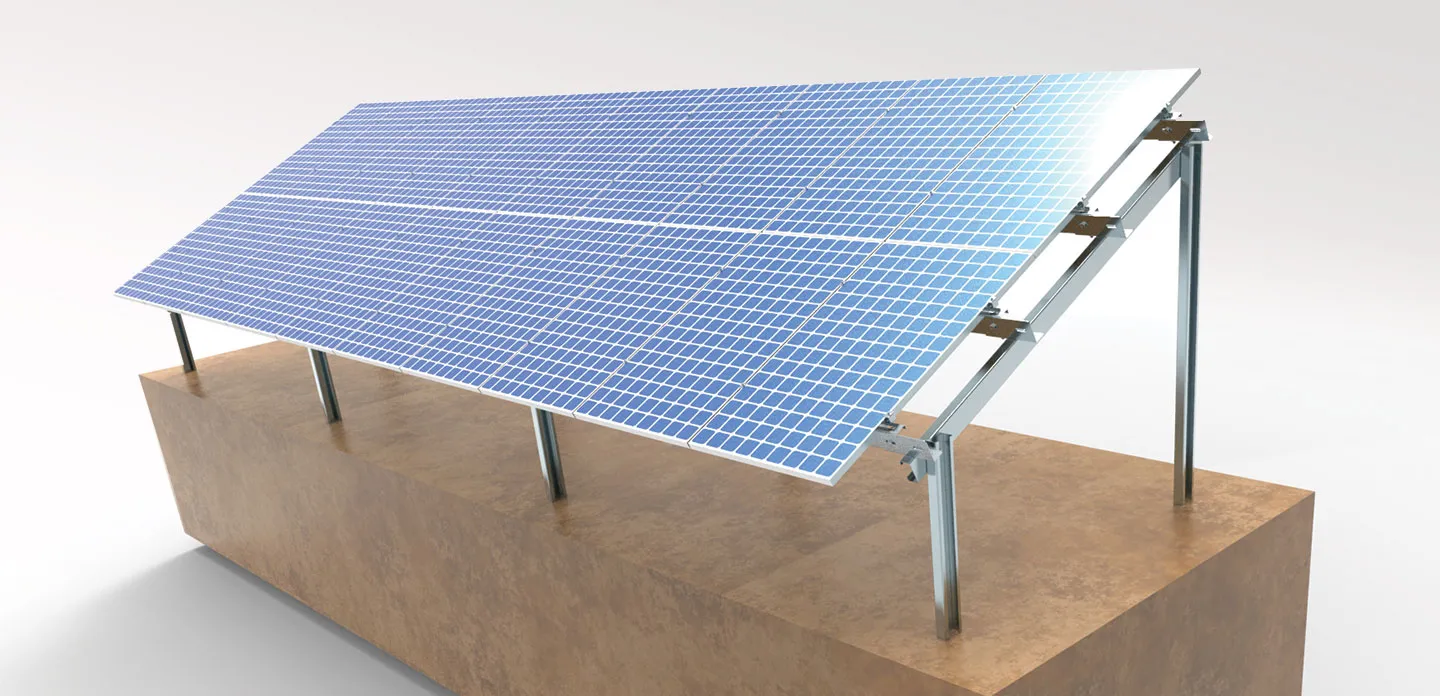

Thanks to the functionality of SOLIDWORKS, ALKA Group’s R&D department has also expanded into different fields. Over the past five years, they have increased the number of industries beyond their traditional sectors of molded products, vehicle manufacturing, and energy. ALKA Group also uses the SOLIDWORKS Simulation program in trailer production for the automotive industry and in its solar energy systems.

According to Gökhan Duman, head of the R&D department, “SOLIDWORKS is perfect for our molding work. And because SOLIDWORKS products are used in various departments within the business, there are no interdepartmental difficulties. Any technical queries are answered quickly by the Armada Yazilim staff as we produce our designs.”

Gökhan Duman and Alphan Sulu, who head ALKA Group’s R&D department, had the following to say about the department’s creation, the company’s work, and using SOLIDWORKS applications: “As a result of the innovative ideas coming out of ALKA Group, the company’s owners—Mr. Ömer and Mr. Akman—initiated the creation of an R&D department. Our team has been in action for six years. One of the main reasons we opted for SOLIDWORKS is that we can easily recycle previous work at the design stage. This means that our designs are functional and timesaving, and SOLIDWORKS provides the opportunity to carry out several tests and experiments, which enables us to move a little further forward every day.”

Staying Ahead of Competition

The R&D department at ALKA Group is hard at work. It is leading the sector and moving ahead of its competitors. Duman also mentioned that because of ALKA Group’s success, foreign companies are showing more interest in Turkey. As a result, there is a more competitive, innovative mindset within R&D. He added that ALKA Group aimed to offer more economical solutions while complying with safety standards in their tenders. To achieve this goal, Duman convinced the management team of the merits of SOLIDWORKS, underscoring its full set of design features and extensibility beyond the core application. Although it took some time for SOLIDWORKS to be used throughout the company, Duman emphasized that by using the SOLIDWORKS analysis feature in the relevant departments, they have been able to develop their processes. As a result, they have started receiving patents and have garnered the respect of global testing and analysis companies in countries such as Spain and Italy.

Duman explained that to keep their customers informed regarding the design work completed using SOLIDWORKS (and in compliance with the applicable regulations of a specific country), ALKA Group would be investing in a SOLIDWORKS Composer™ license. The company intends to use SOLIDWORKS Composer in their municipal work, and in projects in the European Union (EU) and non-EU countries. He further indicated that SOLIDWORKS Composer’s compatibility with Android™ and iOS® means that R&D’s activities can be clearly explained. He also said that the marketing department uses SOLIDWORKS Composer for more effective communications.

Bridge to the Future

Highlighting that ALKA Group uses SOLIDWORKS in 41 countries, Duman indicated that they received the tender for the protection system for Istanbul’s third suspension bridge. Just as it did with the Bosphorus Bridge and the Fatih Sultan Mehmet Bridge, ALKA Group is using SOLIDWORKS as part of the modeling process for the Yavuz Sultan Selim Bridge. He emphasized that the R&D department worked tirelessly to ensure that the dilatation section was safely designed.

Through the effective use of SOLIDWORKS, ALKA Group enhances its laboratory with each passing day. Consequently, its products are of a higher quality and more affordable. In addition, ALKA Group officials stated that maintenance agreements exist for all of its SOLIDWORKS solutions, and that these agreements will be extended because they believe the future requires that they have access to all new features in the application suite.