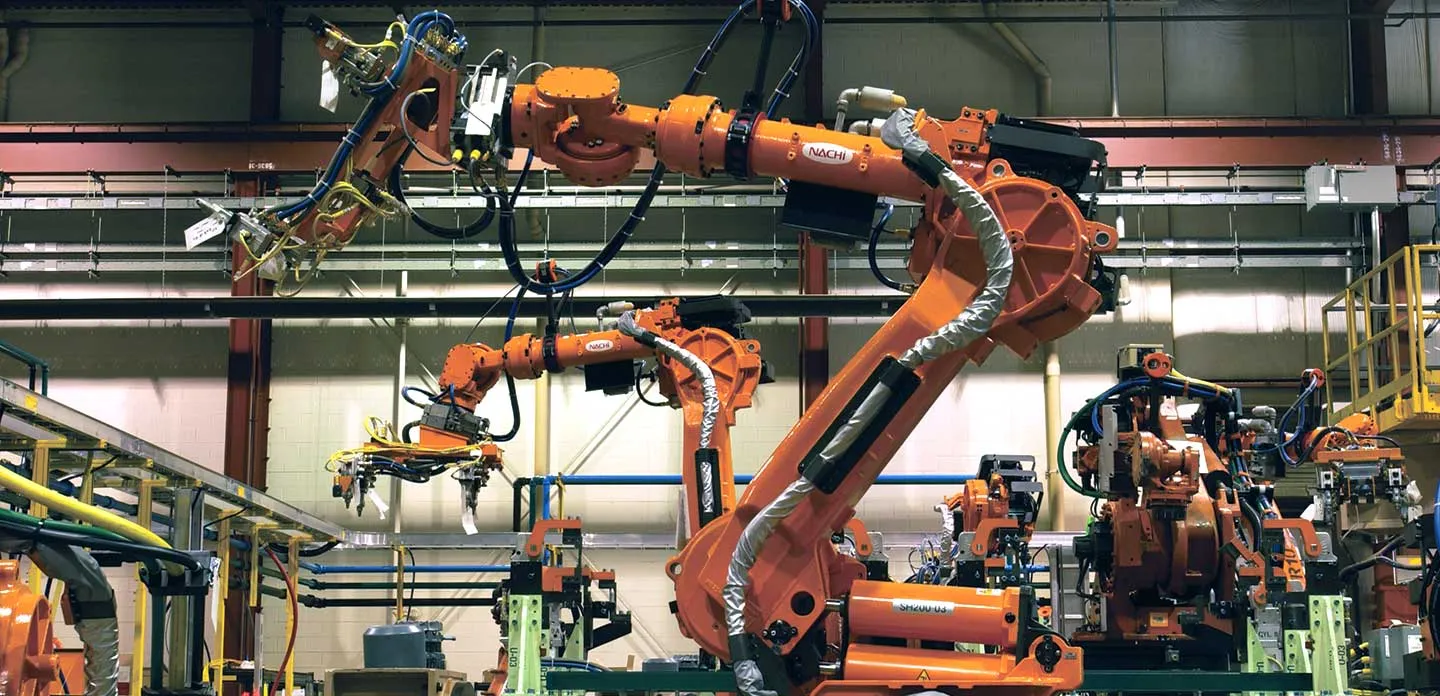

Applied Robotics, Inc. is a leading global provider of specialized end-of-arm tooling and connectivity solutions for the automation and robotics industries. Founded in 1983, the ISO-9001 -registered company has focused on boosting efficiencies and improving manufacturing processes since its inception. Applied Robotics works with other leading robotic manufacturers to provide customers with the latest automation technologies and solutions to satisfy complex automation needs. The company then designs and manufactures innovative automation service solutions, including tool change systems, collision sensors, grippers, and connection systems.

With customers ranging from large Fortune 500 companies to small privately held businesses, Applied Robotics provides solutions that support automotive, manufacturing, welding, assembly, palletizing, material removal, material handling, laboratory, and food-handling applications worldwide. An employee-owned company, Applied Robotics holds more than 40 national and international patents for such inventions as the integrated stud-welding robotics tool changing system, the singleaxis robot force sensor assembly, and robot overload detection.

Until 2008, Applied Robotics used the Solid Edge® mechanical design and E3® electrical design packages to develop, manufacture, and assemble the mechanical and electrical design aspects of its robotic automation solutions. However, according to VP, Director of Engineering Stefan Casey, difficulties related to using the electrical schematics application and recruiting engineers who were trained in the mechanical package prompted the company to re-evaluate its 3D design solution.

“We couldn’t get local support for the electrical schematics software and few of the companies and designers in our area were familiar with or trained in Solid Edge,” Casey recalls. “When we looked around at similar companies in our area and recruited designers and engineers, we kept encountering SOLIDWORKS software. So, we decided to purchase a copy and try it out. That experience resulted in our full transition to SOLDIWORKS in 2013.”

Applied Robotics standardized on SOLIDWORKS solutions— implementing SOLIDWORKS Premium mechanical design and analysis software, and SOLIDWORKS Electrical Schematic design software—because they are easy to use, are well known among the engineering professionals that the company wants to recruit, and provide a cleaner, more integrated approach to mechanical and electrical schematics design.

“Since we implemented SOLIDWORKS, we were able to easily find personnel that doubled the size of our Engineering Department to meet the needs of our growing business,” notes Solutions Manager Tom Marcella. “My colleagues thought that SOLIDWORKS was the better package, and they’ve convinced me that that’s the case. It’s certainly made it easier to recruit strong, qualified people, and our training requirements have been reduced.”

MAKING A GOOD FIRST IMPRESSION WITH DRAWINGS AND SCHEMATICS

Although the electrical and pneumatics schematics that Applied Robotics creates are not overly complex or sophisticated, improving the function is important for the automation company because schematics are shared with customers, contribute to collaboration with mechanical designers, and support system assembly. “The quality of the schematics and drawings is what the customer sees first,” Marcella stresses. “If you have lousy-looking, unprofessional drawings, you’re certainly not starting the project well.”

“Our schematics layouts definitely look nicer and make a better impression with customers,” affirms Electrical and Controls Engineer Michael Spiesbach. “We’ve added a good number of new symbols to our SOLIDWORKS Electrical Schematic database, which enables me not only to create more aesthetically pleasing schematics but also to complete them more efficiently and cost-effectively.”