The first Bowhead Reach bike was delivered to the first customer in November 2018, and Bagg and Gill learned that riders were not content with just riding the bike but were jumping it over obstacles.

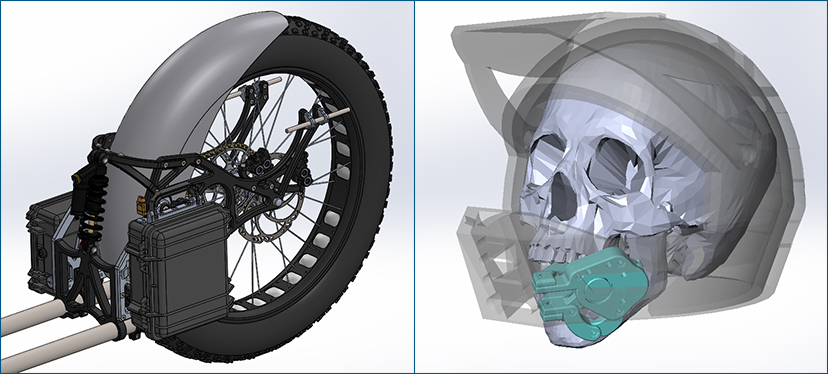

“When we first designed the Reach, we didn’t think that people would be jumping it eight feet into the air,” Gill explains. “After learning more about how our customers use the bike, we took our base design and made modifications to support specialized uses, such as beefing up the shock absorber for jumping or replacing the throttle and braking controls with forearm paddles for use by quadriplegics.”

“SOLIDWORKS for Entrepreneurs not only helped us launch the bike early, but it also has enabled us to address other functions and requirements quickly,” Gill continues. “Whether we’re conducting topology and simulation studies to create a lighter, stronger suspension; using SOLIDWORKS Composer to automate development of our user manual; or leveraging SOLIDWORKS Visualize to create exciting, compelling imagery, SOLIDWORKS solutions support our mission of helping disabled people enjoy the great outdoors.”

Connect with Bowhead Corp. on Facebook, Twitter, Instagram, and YouTube.

Listen to Christian Bagg’s story on SOLIDWORKS Born to Design podcast.