When Fred Friedfeld founded ClearVision in 1949, his goal was to create a great experience for independent eyecare professionals by providing high quality products and exceptional service. Today, David Friedfeld, Fred’s son, continues his father’s focus on quality and service, and ClearVision Optical has grown to become an award-winning leader in the optical industry, designing and distributing eyewear and sunwear for top brands, such as BCBGMAXAZRIA®, BluTech®, Ellen Tracy®, IZOD®, Jessica McClintock®, Op®, Revo®, and Steve Madden®.

ClearVision also produces house brands, including Aspire®

Eyewear, ClearVision® Collection, Dilli Dalli® pediatric eyewear,

DuraHinge®, Junction City®, PuriTi®, and Red Raven®. The privately held company has grown into a global enterprise, serving optical professionals and end customers throughout the United States and in 40 countries around the world.

For the recently launched Aspire Custom Eyewear collection—custom eyewear that blends high fashion with durability—ClearVision sought to leverage its SOLIDWORKS 3D product design data to support custom eyewear configurations online. Previously, eyecare professional partners had no means for configuring orders via the phone and web, which prevented them from sitting down with customers and going through the range of options. What ClearVision needed was a solution for automating configuration, ordering, and fulfillment online, according to Product Engineer Pia Taveras.

“We were looking for a cost-effective way to enable eyecare professionals to configure and order the Aspire brand online when we encountered SOLIDWORKS Sell at a 3D printing tradeshow,” Taveras recalls. “Because we were already familiar with SOLIDWORKS CAD software, which we use to design our products, and no upfront investment or work were required—only a portion of the profit for each piece sold—we decided to implement the technology to support the Aspire Custom launch.”

“We are keenly aware of the trends toward online ordering, bespoke fashion, and manufacturing on demand,” notes Marketing Specialist Jake Friedfeld. “What we liked about SOLIDWORKS Sell technology was that this was the first time that we saw an online configurator that was simple to use.”

MAKING CUSTOMIZED EYEGLASSES AVAILABLE VIA WEB

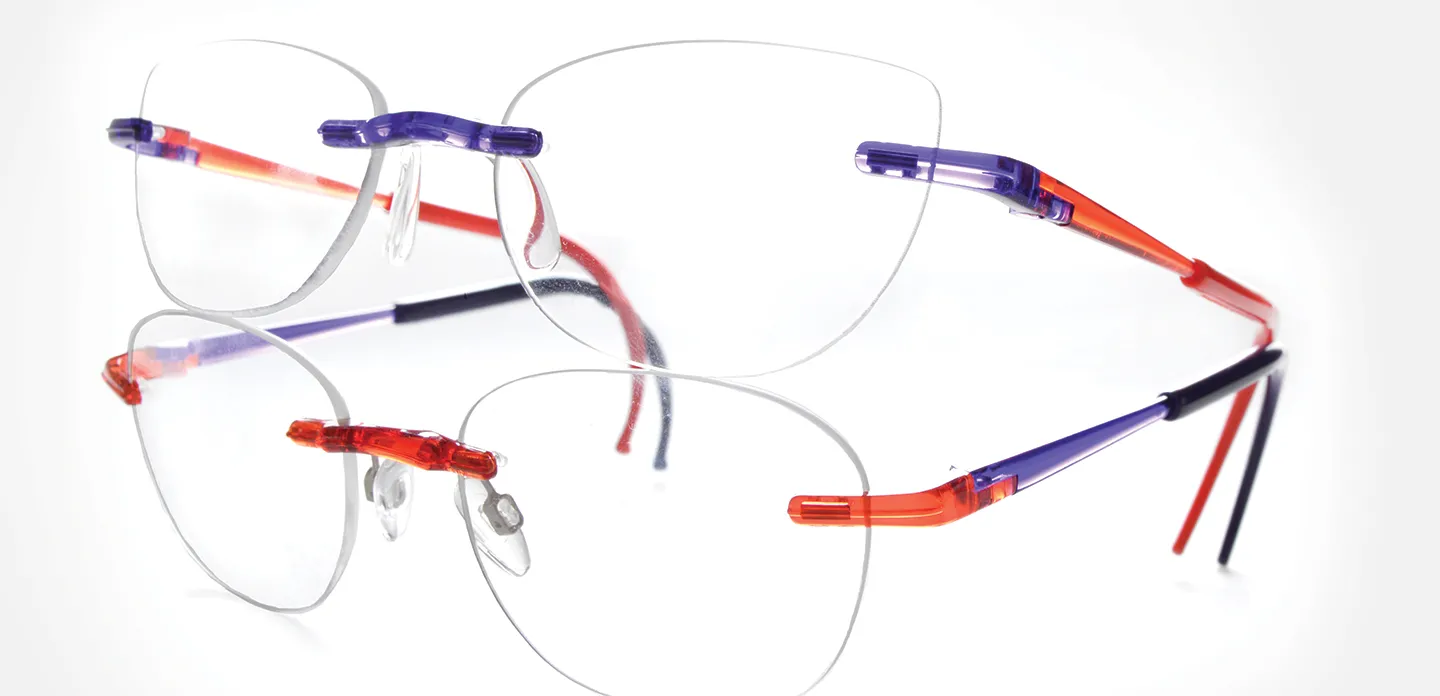

Implementing SOLIDWORKS Sell was as easy as uploading the 22 distinct parts required to make Aspire Custom Eyewear—lenses, bridges, end pieces, temple arms, and temple tips—from SOLIDWORKS and using SOLIDWORKS intelligent mating technology to create connections between parts. With the addition of 12 lens shapes and 18 distinct color variations, users can customize more than one million potential combinations and place orders in real time.

“I created the CAD files for the Aspire Custom line months before we launched the online configurator,” Taveras explains. “It was then a fairly simple process to import them into SOLIDWORKS Sell, assemble them to create the connections, and unleash the configurator. Our Aspire Custom collection is known for its unique coloration, shapes, strength, and customization. Our proprietary nylon polymer derivative material provides the strength, and SOLIDWORKS Sell powers the customization.”