DEC Pharmaceutical Streamlines Operations with DELMIAWorks ERP

New Zealand healthcare product developer and manufacturer gains real-time access to all injection-molding data, thereby automating BOMs, reporting, and increasing cost accuracy

Challenge

Improve operational efficiency, injection-molding production processes, inventory and warehouse management, collaboration, resource utilization, and decision-making by finding a solution that provides real-time access to all injection-molding production, financial, and operational data in order to expand its product portfolio.

Solution

Replace reliance on Access database, Excel spreadsheets, and DOS-based ERP system with the DELMIAWorks Enterprise Resource Planning (ERP) system, including the ERP, Finance, Scheduling, Inventory Management, Forecasting, Tooling Management, Preventive Maintenance (MRO—Maintenance, Repair, Overhaul), Real-Time Production Management, Warehouse Management, Purchasing, and Sales modules.

Results

- Automated generation of bill of materials (BOM) costing information

- Enhanced ability to produce accurate business, operational, and financial reports

- Increased cost accuracy via access to data on variances

- Improved ability to comply with different governmental regulatory requirements

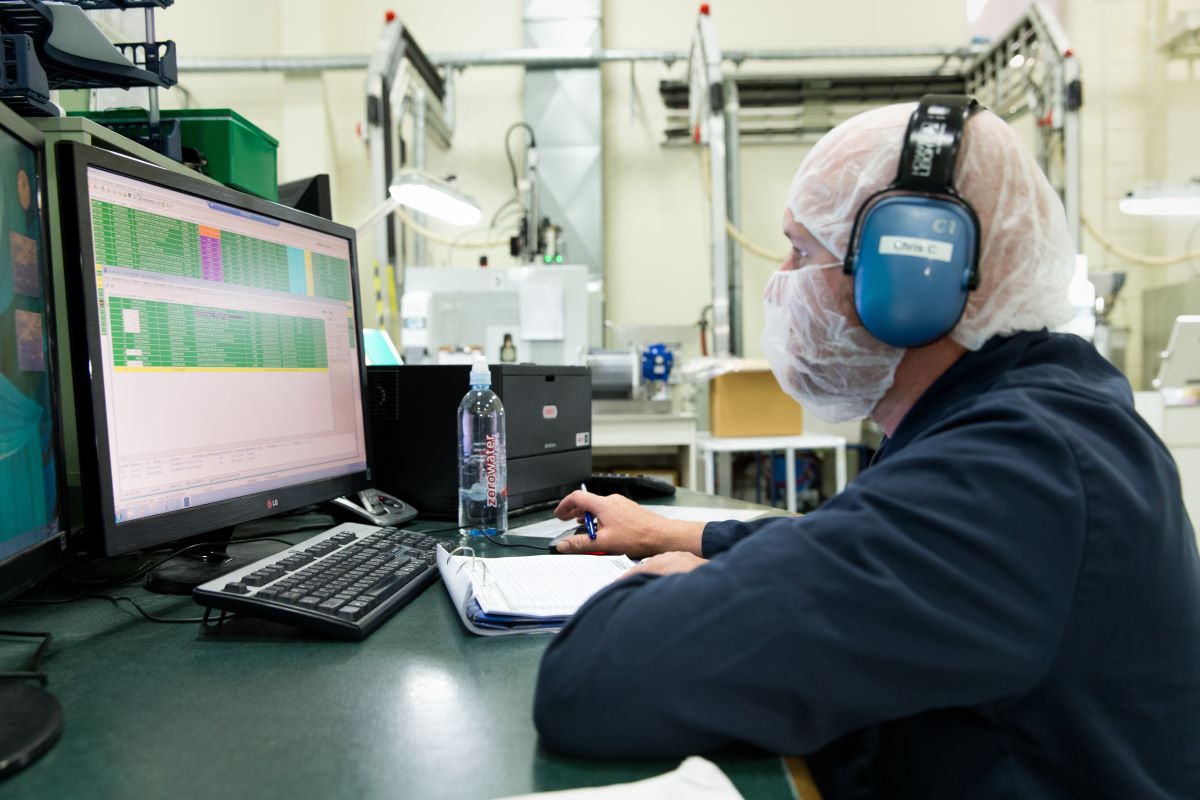

DEC works with innovators who are looking for an end-to-end solution provider that can support them through the entire process of R&D, product development, clinical trials, manufacture, and commercialization. The pharmaceutical business operates in line with Good Manufacturing Practices (GMP).

Until 2022, DEC relied on the combination of an Access® database, Excel® spreadsheets, and a DOS-based ERP system to manage its operations. However, the company needed access to more accurate business, operational, and financial information to realize the productivity gains necessary to grow its product offering, according to CFO Phil Webster.

“Our goal is to increase our product portfolio, but without accurate information on our operations it’s difficult to identify areas for improvement,” Webster stresses. “We simply needed to gain a better understanding of our cost structure, variances, and operations, which was very difficult with the legacy systems we had.” DEC’s sister company used DELMIAWorks® enterprise resource planning (ERP) system, and DEC management recognized that it could resolve their challenges, too.

Gaining Control of the Data

With the DELMIAWorks ERP implementation, DEC management can access more accurate cost and variance information on injection-molding runs so they can make beneficial adjustments. “The lack of transparency and flexibility of the old costing information associated with BOMs is an example of why we needed better visibility of our BOMs and cost structure,” Webster adds. “With the DELMIAWorks ERP system, we not only improved the accuracy of our costing information but have also enhanced our ability to plan, forecast, and schedule production runs, and provided transparency on variances in the system, so we can address things in real time.”

Related Resources

Streamlining Operations and Report Generation

Capitalizing on the DELMIAWorks ERP implementation, DEC is streamlining its operations both from management and operator perspectives. “The benefits of the DELMIAWorks ERP system are substantial,” Webster stresses. “Before, we couldn’t access all of the information that we needed to generate reports that would help us make decisions that would help streamline our operations. Using DELMIAWorks, we can push out profit and loss reports, variance reports, and goods received on inventory reports.”

With DELMIAWorks DEC management can also ascertain and monitor efficiency levels within its factory by accessing accurate information from the system and leveraging it to streamline operations. “We really couldn’t grow with the old redundant systems but are now positioned to take those steps with DELMIAWorks ERP,” recounts Webster.

With the DELMIAWorks ERP system, we not only improved the accuracy of our costing information, but have also enhanced our ability to plan, forecast, and schedule production runs, and provided transparency on variances in the system, so we can address things in real time.

Achieving Regulatory Compliance

With the more accurate operational data provided by the DELMIAWorks ERP system, DEC will be able to comply with the myriad of differing governmental regulatory requirements more easily for healthcare products and medical devices around the world. “In addition to helping us get leaner in our operations so we can grow, DELMIAWorks ERP will help us modernize other aspects of our business.” Webster points out. “With DELMIAWorks ERP, complying with these requirements will be easier in the future as we begin to utilize all the functionality and capability of the system. It will facilitate the information being readily accessible and at our fingertips.”

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.