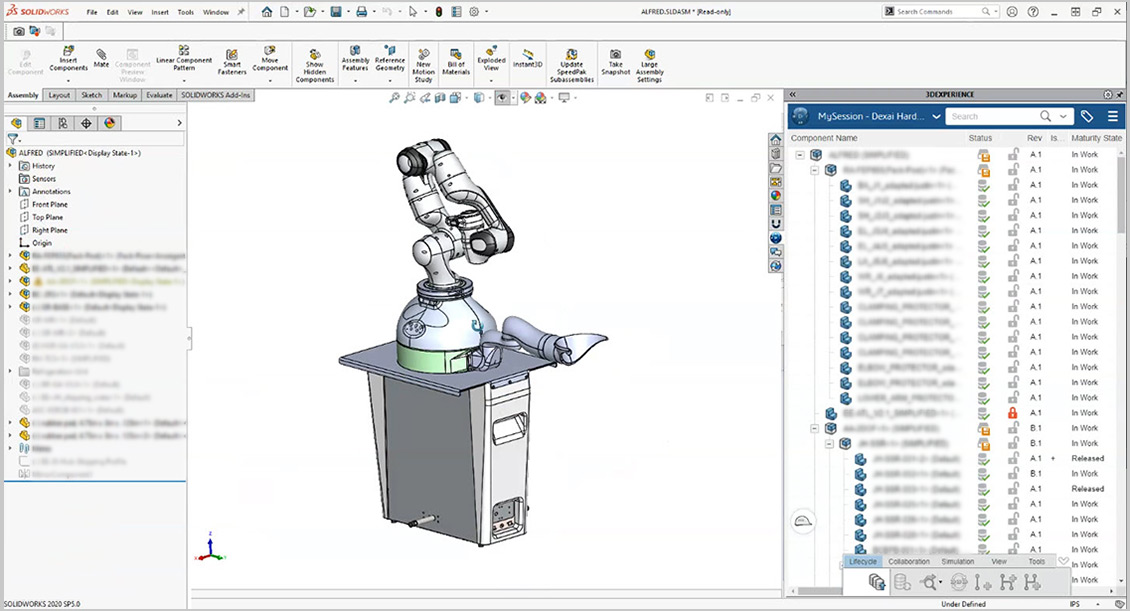

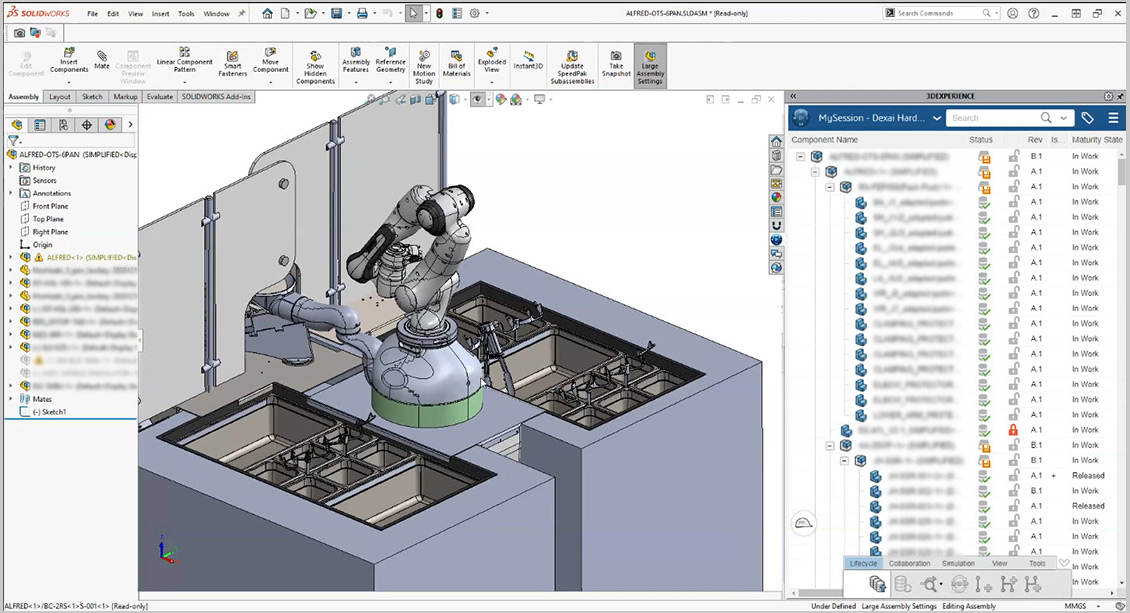

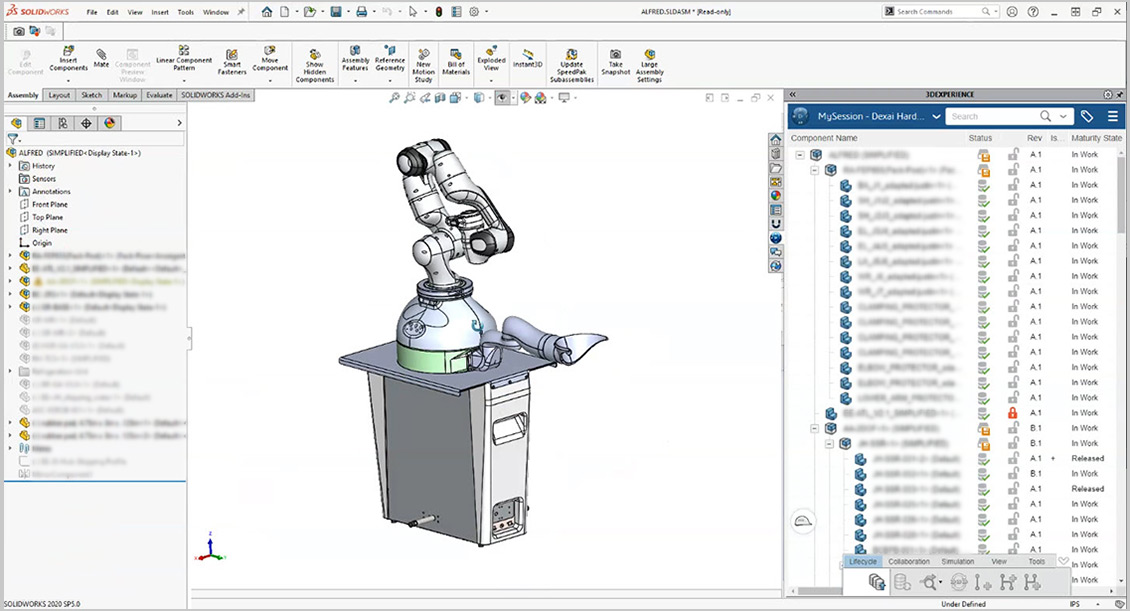

“There are three main phases in our hardware design process: functionality, reliability, and manufacturability. A designer will typically focus on each phase in sequence, all while keeping in mind usability,” Mechanical Engineer Rana Odabas notes. “Working on the cloud has saved us considerable design time because we can have multiple people working on the same project simultaneously. That’s a huge improvement from the days when we were passing CAD files back and forth.”

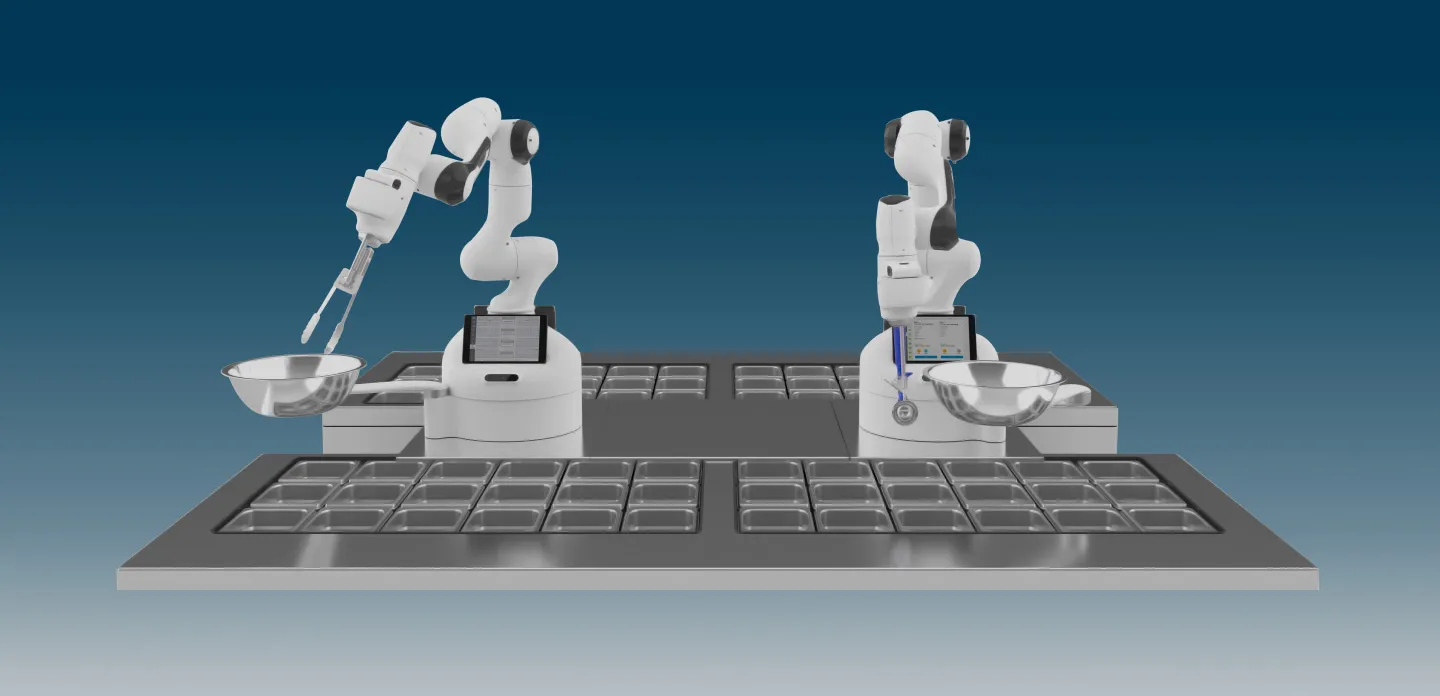

In developing Alfred, Dexai faced additional engineering challenges that most industrial operations robots do not face. Because Alfred must operate and interface in a kitchen where many people are working while simultaneously working with food, Dexai must adhere to the National Sanitation Foundation regulations. “We began with a salad assembly task with the robot selecting romaine lettuce, tomatoes, cucumbers, and other ingredients to assemble into a meal,” Rooney adds. “The robot needs to use separate utensils and return them to the respective areas to avoid cross-contamination that might trigger a food allergy.” With the combination of SOLIDWORKS and 3DEXPERIENCE Works solutions, Dexai Robotics has the tools to roll out these capabilities faster and more efficiently.