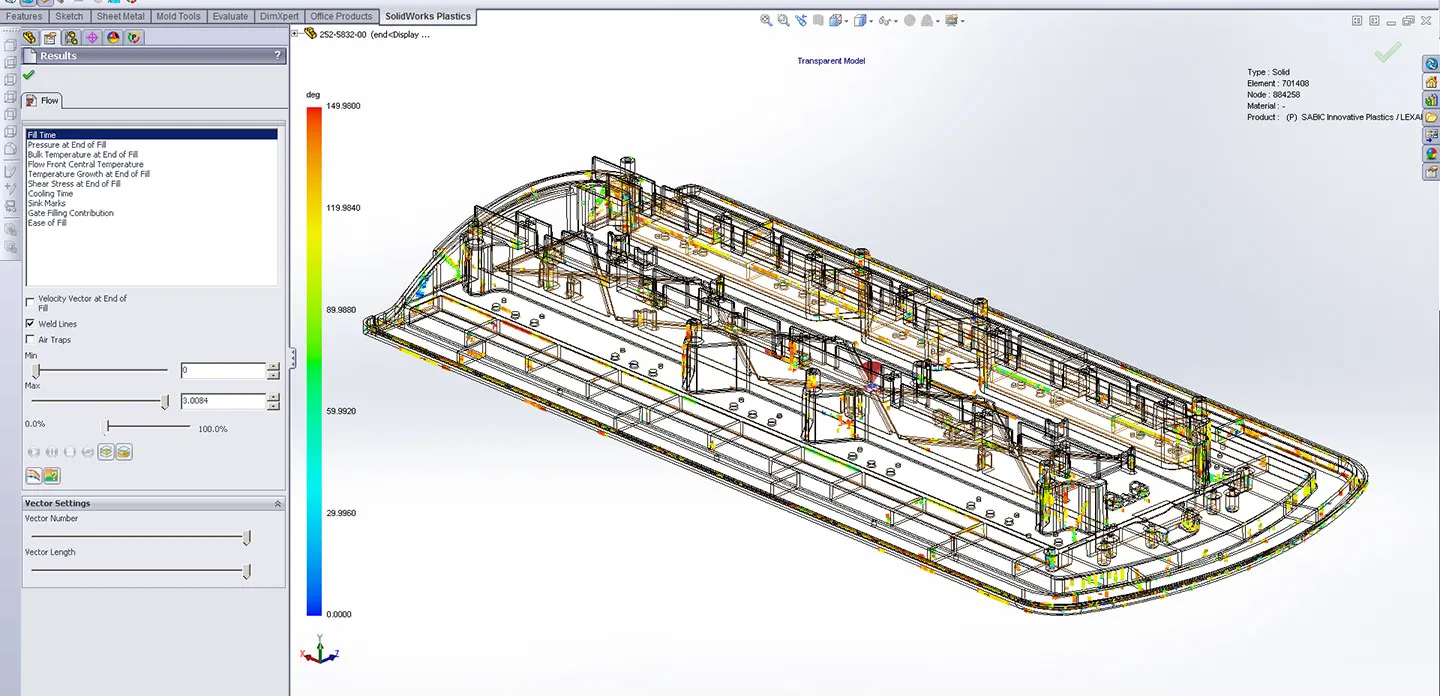

As the world’s largest manufacturer of emergency warning products, ECCO (Electronic Controls Company) depends on the development of high-quality, injection-molded plastic parts. The company’s backup alarms and warning lights for commercial vehicles—and red and blue warning lights for emergency vehicles—typically operate outdoors, where they are exposed to all types of weather. In such an environment, ECCO often prefers to use plastic parts because they don’t rust. With light lenses, using plastics for optical components is a necessity. Since implementing SOLIDWORKS Professional and SOLIDWORKS Premium design software in 2001, the Idaho-based company has realized dramatic productivity gains, cutting design cycles and expanding its product offering. The implementation of the SOLIDWORKS Enterprise PDM product data management system in 2010 produced additional benefits. In 2012, ECCO turned to Dassault Systèmes SOLIDWORKS Corporation for a solution for optimizing the manufacturability of plastic injection- molded parts. “Prior to 2012, we relied on our tool manufacturer to spot and address injection-molding issues,” recalls Mechanical Design Engineer John Aldape. “However, when we received glass-filled nylon alarm enclosures with surface-knitting issues, we decided to investigate mold-filling simulation technology. We wanted to independently assess how a mold would fill and where knit lines would be, instead of waiting on iterations with the toolmaker.” ECCO obtained SOLIDWORKS Plastics Professional injection-molding simulation software. “The software showed us enough that we knew it would be valuable,” says Mechanical Design Engineer Nick Thompson. “SOLIDWORKS Plastics is easy to use, simulates how the plastic will fill the mold, and shows how the molded part will look. We realized that we could use it to avoid manufacturability issues.” “We also foresaw how SOLIDWORKS Plastics would help us refine the production of optical components, such as lenses,” Aldape adds. “We want our parts to be smooth, clean, and structurally sound, and we believed SOLIDWORKS Plastics would help us achieve those goals.”

Simulate Mold Filling Saves Time and Money

ECCO uses SOLIDWORKS Plastics mold-filling simulations to optimize plastic injection-molded parts on the front end, which saves time and money by minimizing iterations with the moldmaker on the back end. The company still values the expertise of its tool manufacturer, but having access to mold-filling simulations during design keeps potential manufacturing issues to a minimum. “Although we still leave things like mold inserts, sizes, forms, and the presses required to the toolmaker, being able to visualize how the plastic will flow in the mold gives us greater control over how the final part will look,” Aldape notes. “If we didn’t have SOLIDWORKS Plastics, we wouldn’t have as much confidence in the manufacturability of a design. It helps us avoid going back and forth with the moldmaker after the fact, which saves time and reduces costs.”