Optimize Efficiencies

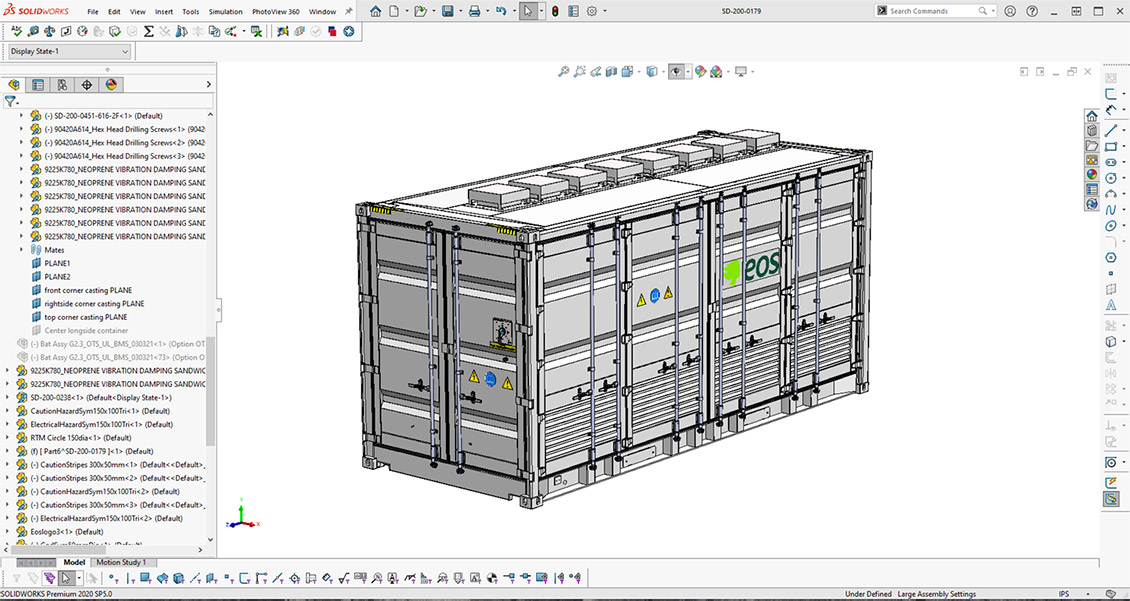

Since adding SOLIDWORKS Simulation solutions and beginning SOLIDWORKS PDM implementation, Eos has shortened its development cycle from multiple years to 12 months and realized 60 percent higher output through the improved design and performance of its Gen 2.3 battery. Plus, the company has advanced the development of its Gen 3 battery, which increases container storage capacity from 500 KWh to 750 KWh.

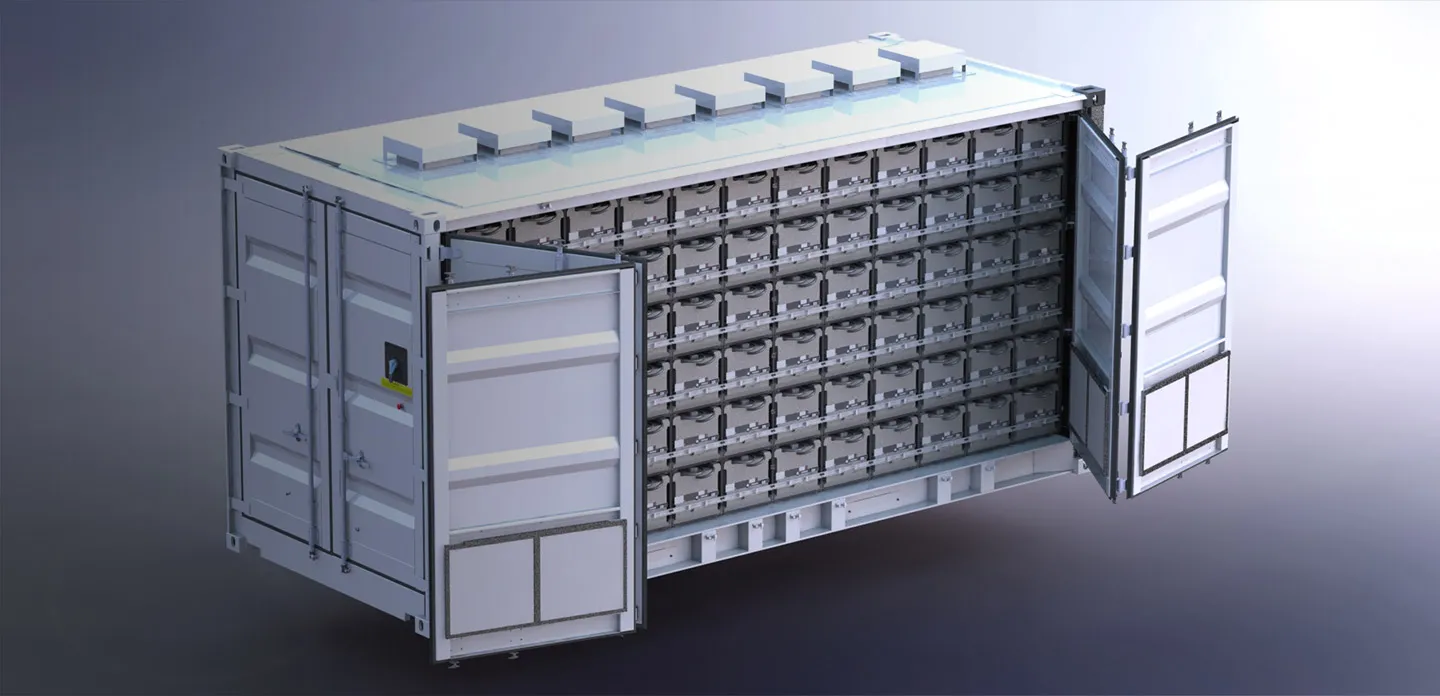

Eos leveraged SOLIDWORKS Simulation Premium and SOLIDWORKS Flow Simulation to optimize the container and the racks that hold the batteries inside the redesigned container, as well as to improve the efficiency of the storage system’s cooling system that cools the 144 batteries (weighing 6,000 pounds) inside the storage container.

“The cooling system pushes a column of air from the bottom row to the top row and turns the air over several times each minute,” Dubois explains. “Running a flow simulation revealed that the airflow was bypassing some of the batteries, so we made design changes to optimize airflow and were able to improve our thermal gradient from 24° C to 7° C, which was a substantial improvement in performance.”

Prepare for Growth

Dubois concludes, “We’ve improved the product, improved our processes, and improved our documentation using SOLIDWORKS solutions. If this market turns out to be as big as we think it will be, our business is primed for explosive growth.”