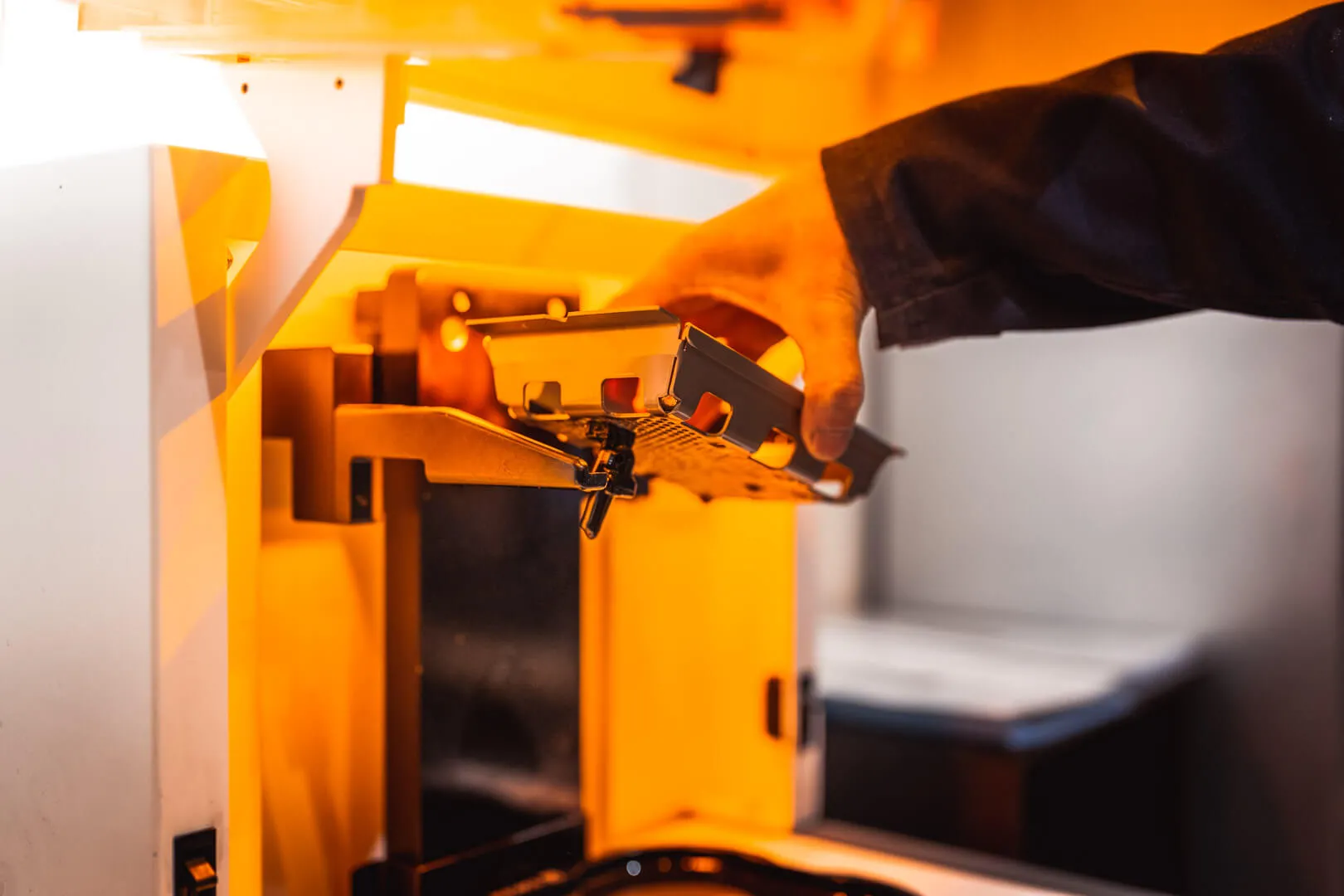

When industrial designer Gauthier Laviron and salesman Bastien Vanlathem had trouble finding replacement parts for their vintage cars, they realized the rarity of certain spare parts created a business opportunity. They launched GRYP 3D in 2018 and today have a bourgeoning 3D print vintage car replacement parts startup with five employees in Bordeaux, France.

Photo Credit 3dnatives.com

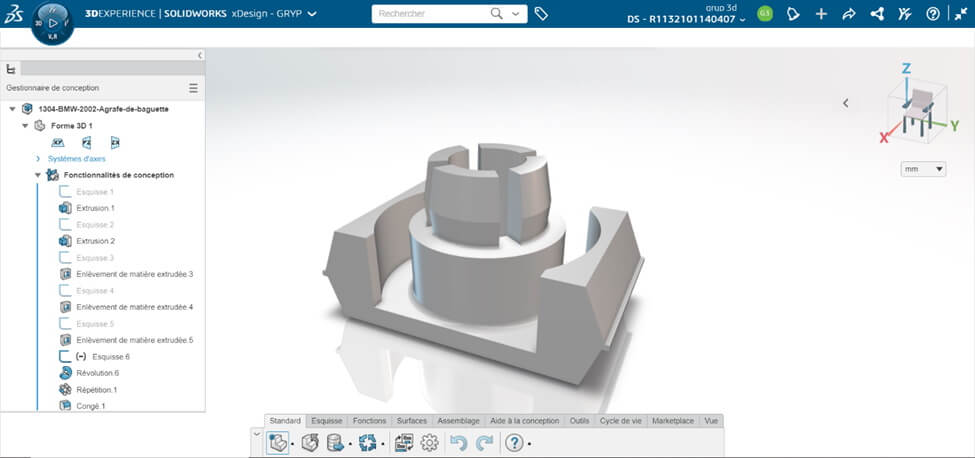

GRYP 3D prints parts from native CAD design files or 3D scans of damaged/worn-out parts. The startup initially used open-source and low-cost design software, which became problematic due to clients' file formats issues. Laviron explains, "If the file is not set up correctly, it's like a photo that you save with the wrong resolution. It can negatively impact manufacturing." Such software also became a hindrance due to licensing issues and the re-training required for new employees.

GRYP needed a single solution that everyone knew how to use, so it formalized its workflows on the 3DEXPERIENCE® platform. It implemented the 3D Creator, Collaborative Business Innovator, and Collaborative Industry Innovator roles for designing and 3D printing vintage car parts because the platform can read all major CAD file formats.