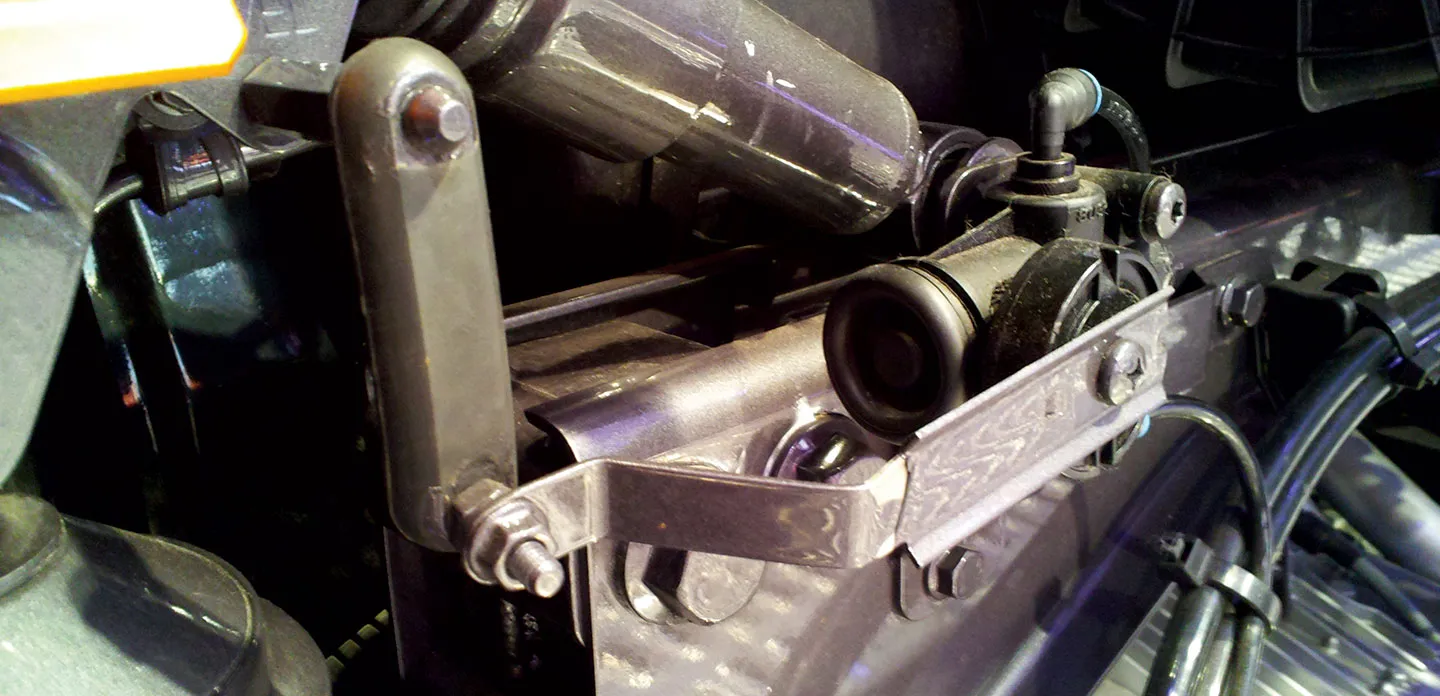

Since introducing the Hadley horn—a recognizable icon in the trucking industry—Hadley has been producing high-quality parts and systems for the heavy truck and transit industries. A Tier 1 supplier to truck original equipment manufacturers (OEMs) and Tier 2 supplier to suspension manufacturers, the company designs and manufactures components, systems, and products for vehicles, tractor trailers, and associated aftermarkets. Hadley also makes products for the transit and shuttle bus, recreational vehicle (RV), motor coach, and specialty vehicle markets. Building on its leadership position in truck and transit mirrors, height control valves, and air horn systems, Hadley has expanded its product offering to include electric horns, mini air compressors, electronic height control systems, and interior vehicle systems. Hadley’s products are common pieces of original equipment on over-the-road, tractor-trailer rigs, as well as in the consumer market on SUVs, 4x4s, vans, pickup trucks, motor homes, motorcycles, powerboats and sailboats. Until 1999, Hadley used AutoCAD® 2D design tools. That’s when increasing competition and greater use of injectionmolding manufacturing techniques prompted the company to transition to a 3D development platform, according to Principal Engineer Dick Winter. “We needed to model parts in 3D to expand our product offering and compete,” Winter recalls. “More of our products required combinations of molded plastics, rubber, and stamped metal, and we believed that the ease and speed of modeling in 3D would boost productivity and help us grow our product line,” Winter says. “As more customers and partners moved to 3D, we also needed to be able to work more efficiently with their design data.” Hadley chose the SOLIDWORKS development platform because it’s easy to use and provides the best value for the price. The company now relies on SOLIDWORKS solutions— including SOLIDWORKS Standard design, SOLIDWORKS Professional design, SOLIDWORKS Premium design and analysis, SOLIDWORKS Simulation structural analysis, and SOLIDWORKS Flow Simulation computational fluid dynamics (CFD) analysis software—to develop its products. “We especially liked the fact that SOLIDWORKS listens to its users and actually includes customer suggestions in new releases,” Winter notes. “Because we value the quality of the technical support that we receive from our local reseller DASI Solutions, we have kept our maintenance subscription up-to-date, which enables us to remain current and compatible with customers and partners.”

Improving Design-to-Production Cycles

With SOLIDWORKS design solutions, Hadley has realized productivity and quality gains, particularly during the development of injection-molded parts and associated tooling. Using SOLIDWORKS software, Hadley has reduced the mold and tooling development process—designing, quoting, and fabricating molds and tooling components—by 20 percent, while simultaneously improving tooling accuracy. “SOLIDWORKS helps us improve design manufacturability, such as making sure the model has sufficient draft, and reduce iterations with our moldmaker,” Winter stresses. “With improved visualization in 3D, we can sit down with the moldmaker and go over part and mold design. This allows us to see potential issues inside the tool and quickly make changes in the design and mold so we get the part right the first time. Improving the accuracy of our parts and tooling saves time, but also produces cost savings because it can cost from $5,000 to $10,000 to fix a tool.”