Challenge

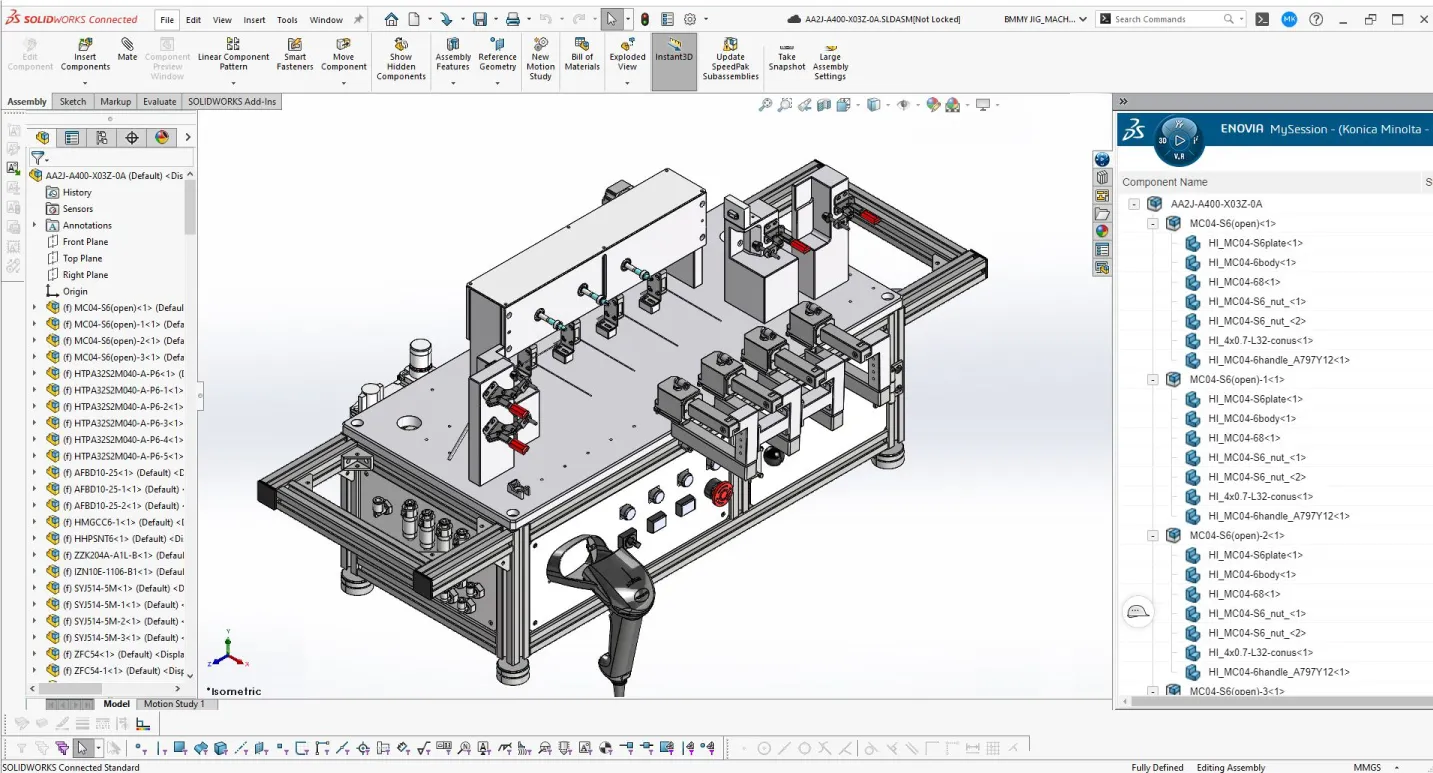

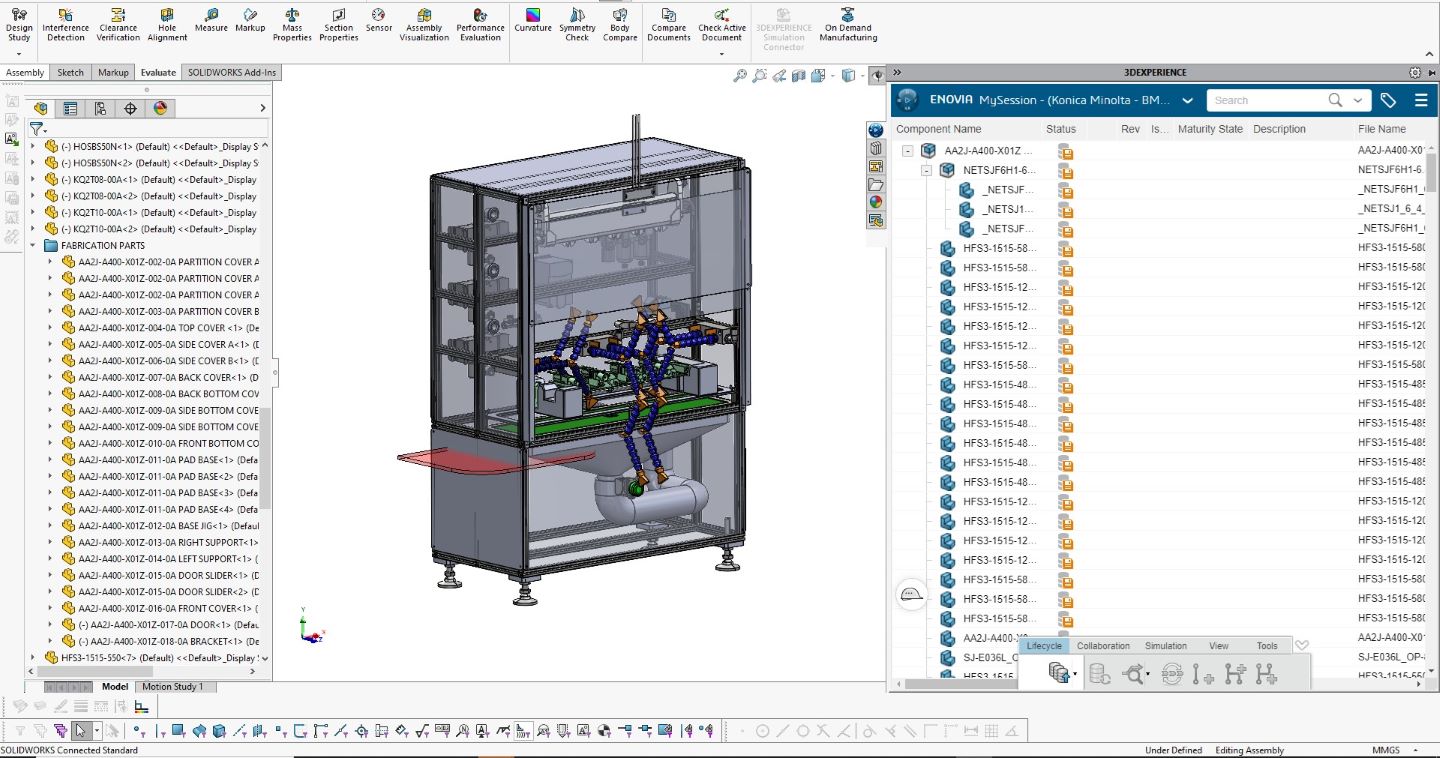

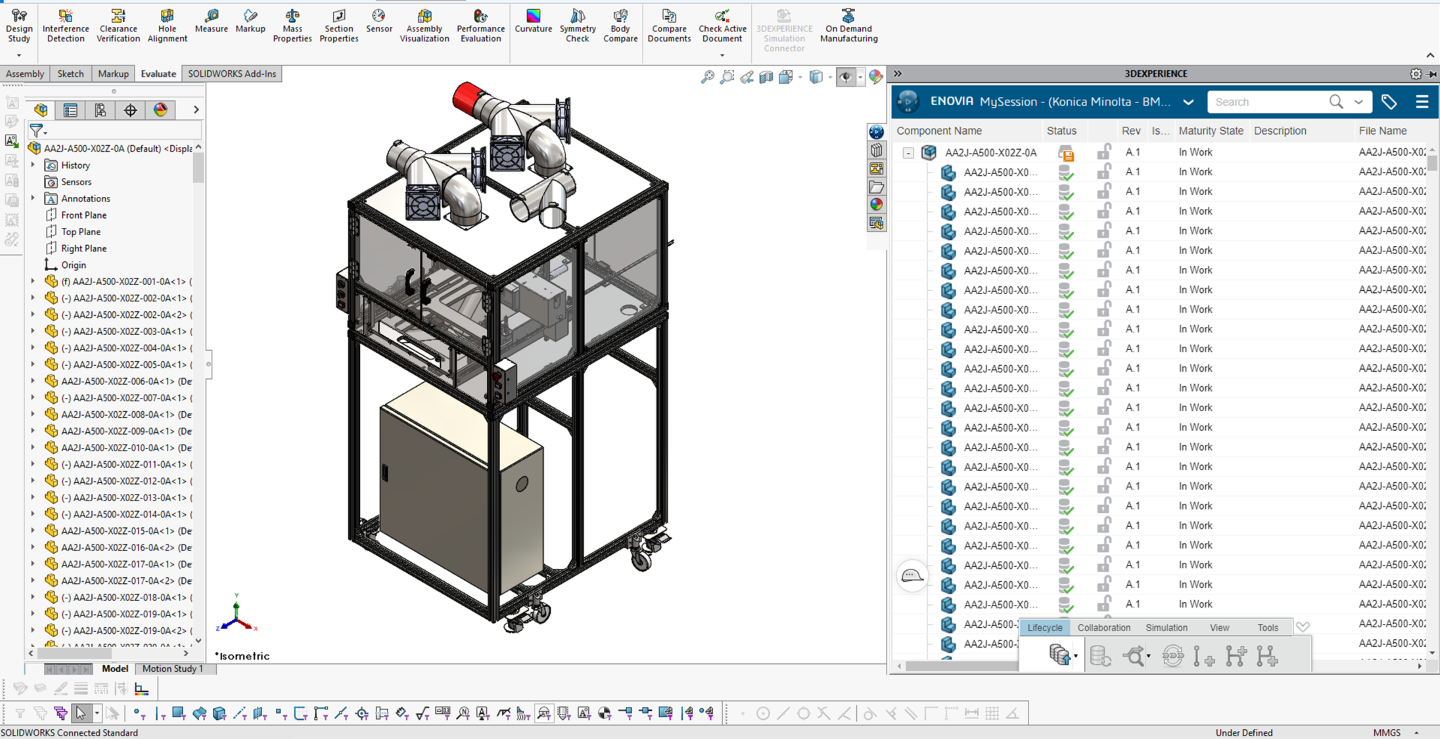

Improve data management to eliminate revision errors and rework costs while simultaneously shortening development cycles for production tooling (e.g., jigs, fixtures) for the manufacture of high-tech multifunction copiers and office equipment.

Solution

Add modeling, design, collaboration, communication, and data management solutions from the 3DEXPERIENCE Works portfolio on the cloud-based 3DEXPERIENCE platform—including 3DEXPERIENCE SOLIDWORKS, 3D Creator, Collaborative Designer for SOLIDWORKS, Collaborative Business Innovator, and Collaborative Industry Innovator—to its existing SOLIDWORKS implementation.

Results

- Cut development cycles by 25 percent

- Eliminated rework and associated costs

- Improved and automated data management

- Replaced Microsoft Teams with the 3DEXPERIENCE platform as communications channel