Challenge

Improve collaboration and increase product development throughput while improving quality by eliminating communication errors with outsourced manufacturing partners and resolving product release delays associated with manufacturing defects and internal revision errors.

Solution

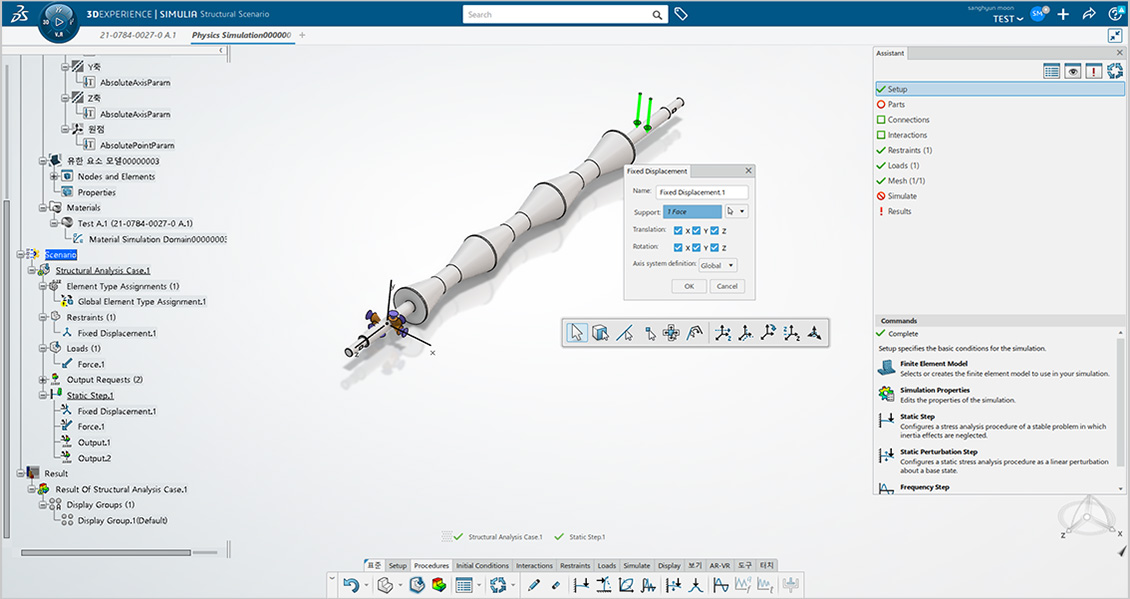

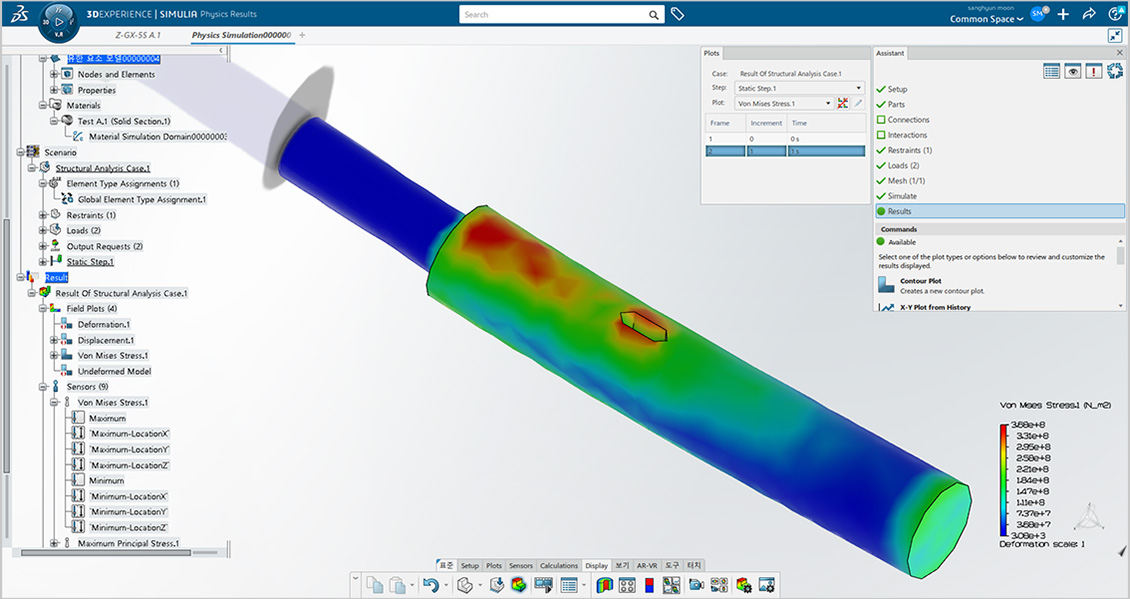

Implement 3DEXPERIENCE SOLIDWORKS® Premium design software in concert with 3DEXPERIENCE® Works solutions on the cloud-based 3DEXPERIENCE platform, including Collaborative Industry Innovator and Collaborative Business Innovator.

Results

- Shortened product development cycles by 20 percent

- Reduced prototyping costs by 30 percent

- Decreased defects related to revision errors by 20 percent

- Improved collaboration and communication dramatically