Challenge

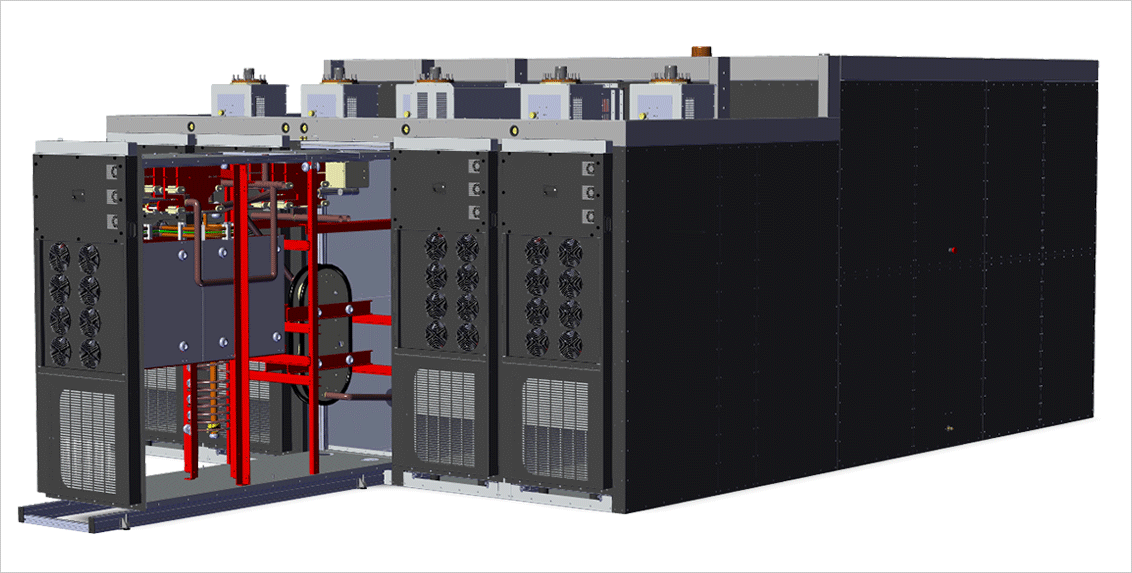

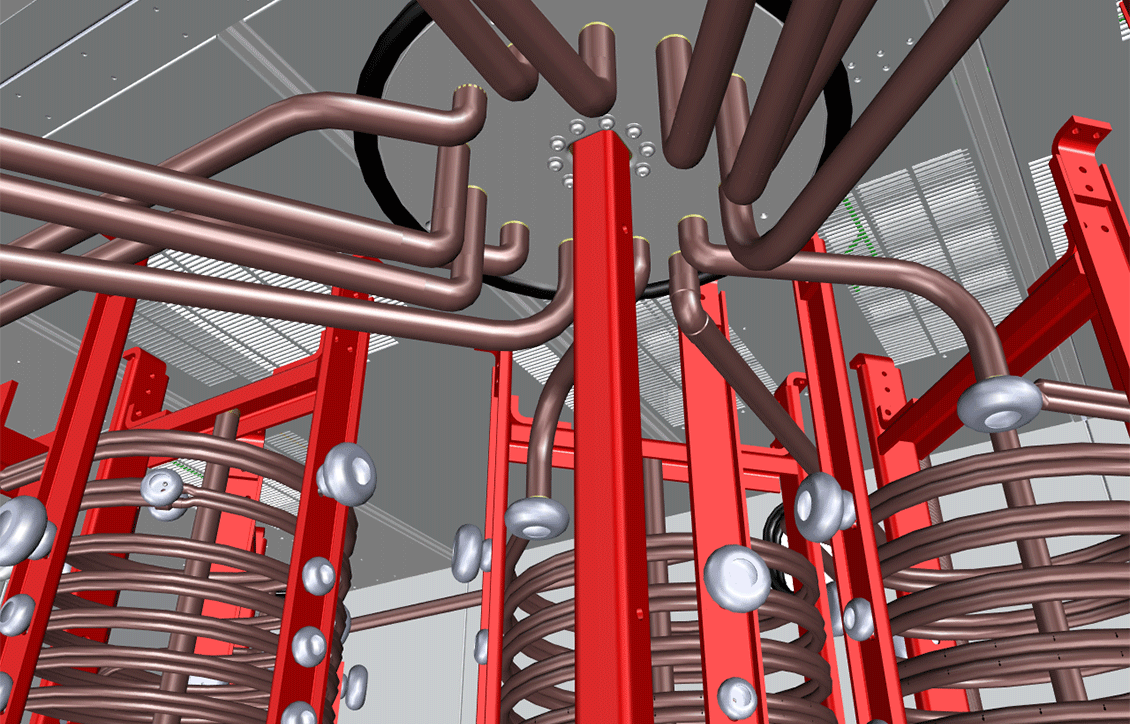

Advance the development of radio broadcast transmitters, navigational radio beacons, eLoran transmitters, weather transmitters, and sonar systems by improving design performance, reducing product weight and volume, and shortening development cycles to accelerate time to market

Solution

Implement integrated SOLIDWORKS® mechanical design, electronic (PCB) design, simulation, product data management (PDM), visualization, and technical communication software solutions

Results

- Shortened development cycles from 18 months to one year

- Cut transmitter weight in half via simulation

- Dramatically expanded product line

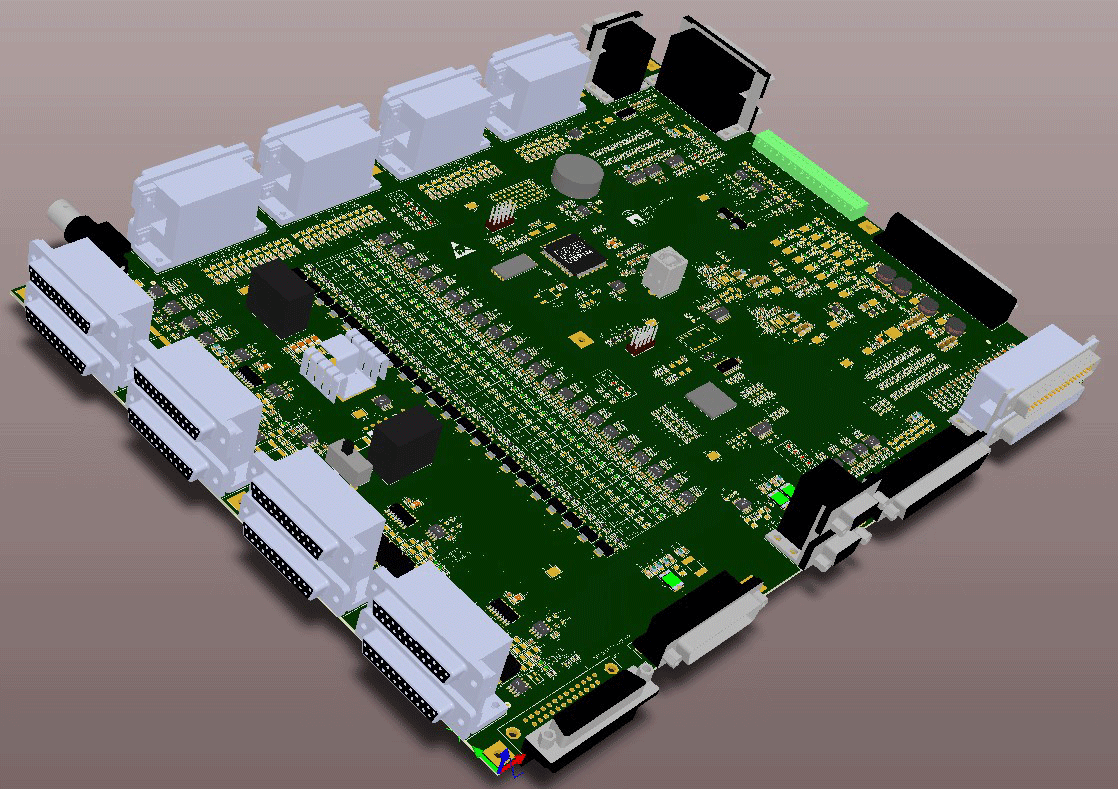

- Designed largest circuit board in company history with SOLIDWORKS PCB