Optar Technologies Limited specializes in the design and manufacture of air intake filter housings and systems for rotating machinery, compressors, and turbines. Founded in the United Kingdom in 2005 to supply and install gas turbine air intake filters for international energy companies, the design and engineering consultancy leverages its traditional strengths in large power station projects to also work on air intake systems for a variety of smaller applications.

In order to offer a complete set of engineering services, including design, engineering, validation, project management, and manufacturing services, the firm needed to utilize advanced design, simulation, and product data management (PDM) tools, according to Managing Director Andrew Thomson. Optar acquired SOLIDWORKS Premium design software in 2008, and while the software enabled the consultancy to perform design modelling, Optar had to rely on outside partners to perform the structural and fluid flow analyses that are frequently required for air intake filter housing projects.

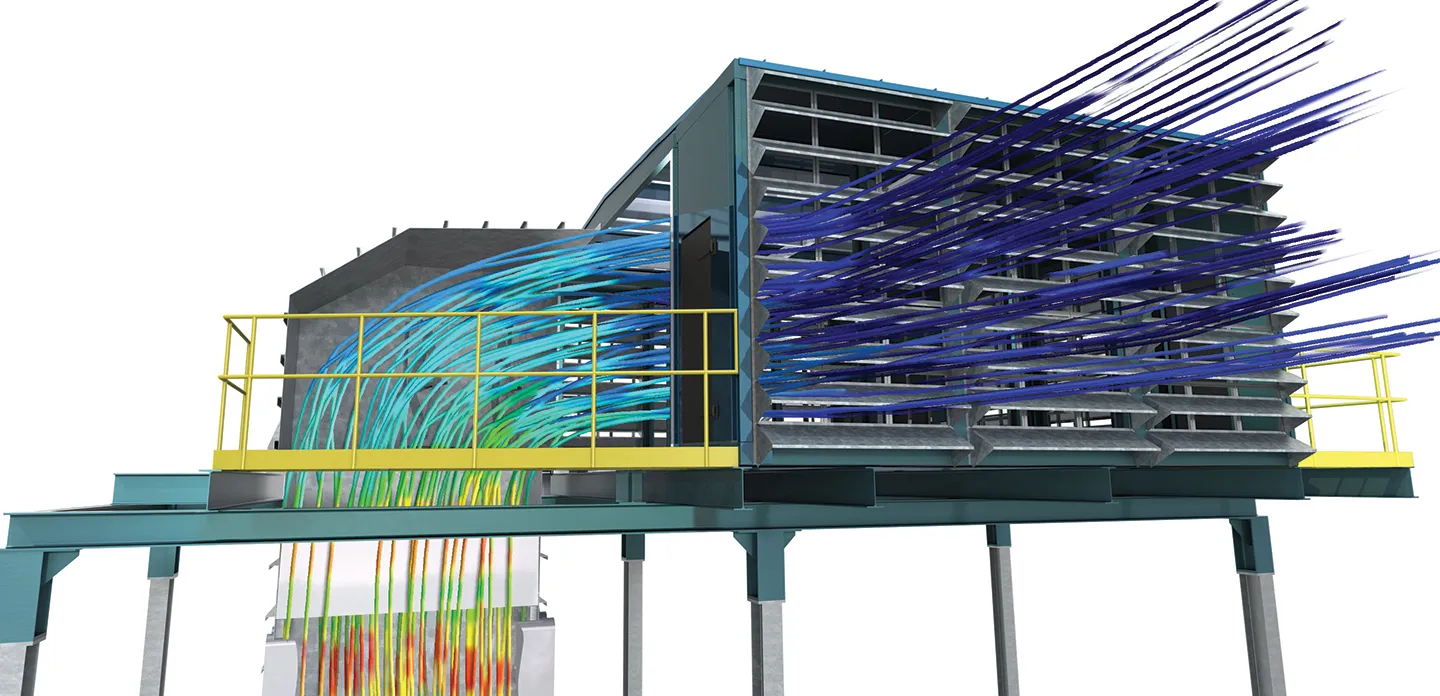

Although using external resources to perform design simulation and validation was adequate, the practice added unnecessary delays and costs to the process and negatively affected the firm’s pricing and competitiveness. To eliminate these additional costs and delays, Optar decided to bring design simulation and validation in-house, and began evaluating both structural and fluid flow phenomena with computational fluid dynamics (CFD) and finite element analysis (FEA) software solutions. The consultancy also needed an automated PDM system to satisfy the requirements of its ISO 9001 certification renewal.

Because of the positive experience that Optar had with SOLIDWORKS Premium design software, the firm chose to add SOLIDWORKS Simulation analysis and SOLIDWORKS Flow Simulation analysis software in 2012, and SOLIDWORKS Enterprise PDM (EPDM) software in 2013. Optar selected SOLIDWORKS solutions because they are easy to use, provide all required capabilities, and are completely integrated. “It was a natural thing for us to go from using SOLIDWORKS design to using the SOLIDWORKS Simulation and PDM packages,” Thomson says.

SAVING TIME AND MONEY THROUGH IN-HOUSE SIMULATIONS

Since adding SOLIDWORKS Simulation and SOLIDWORKS Flow Simulation software, Optar has reduced the time and costs of design simulation and validation by bringing the processes in-house, as well as improved the performance of its air intake designs. For example, on a 720 MW power station project, simulations proved that an Optar design increased 0.1-micron particulate filtering efficiency for unburnt hydrocarbons from 15 percent to 90 percent. In addition to eliminating unnecessary delays and costs at Optar, bringing simulation capabilities in-house is saving the firm’s clients money.