The Outdoor Group, LLC is dedicated to developing the world’s most high-tech and prestigious compound bows and archery equipment. As the parent company of Elite Archery, Perfect Form Manufacturing, Scott Releases, Custom Bow Equipment, Duel Game Calls, Solid Broadheads, and Winner’s Choice Custom Bowstrings, the privately held company has assembled the top brands in archery to develop the industry’s most “Elite” bows.

Based in Henrietta, New York, The Outdoor Group focuses on the use of advanced design, engineering, and manufacturing technologies to produce bows with the highest levels of shootability. By combining proven technology and components made by recognized leaders in their field with modern design and manufacturing techniques, the company strives to make its Elite™ bows worthy of their name.

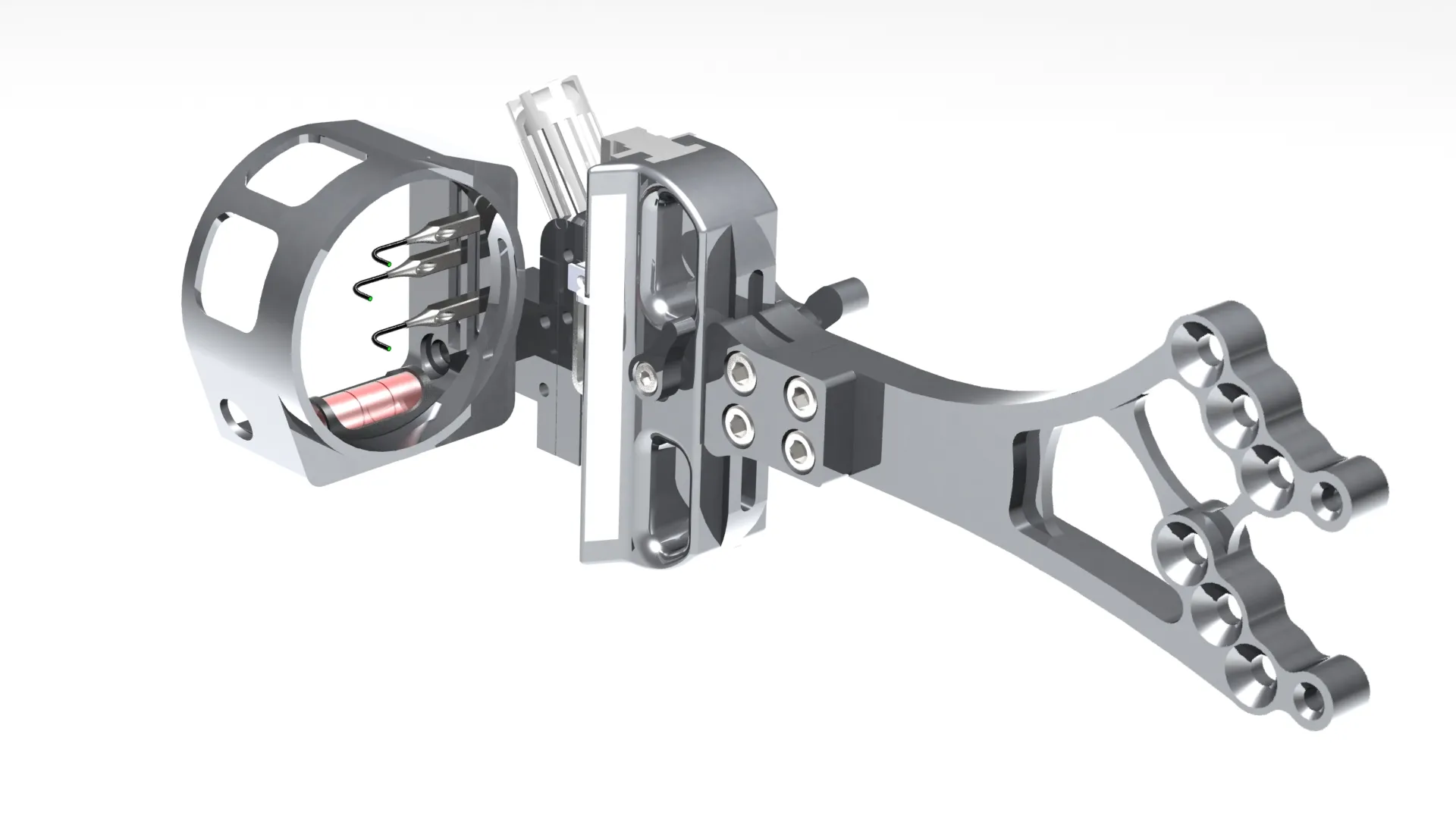

According to Lead Engineer Mike Derus, the archery equipment manufacturer realized from the start that it would need to leverage 3D design, engineering, and manufacturing solutions to achieve its ambitious product development goals. “In launching a new product development organization that is tasked with integrating the product designs of our subsidiaries into a unified effort, we needed a robust yet easy-to-use development platform,” Derus explains. “Designing rapidly, validating quickly, and manufacturing efficiently were critical requirements. After evaluating available packages, we chose SOLIDWORKS solutions.”

The Outdoor Group selected SOLIDWORKS Professional and SOLIDWORKS Premium design software, as well as SOLIDWORKS Simulation Professional analysis software, because the solutions are easy to use, provide an efficient approach to design analysis, and integrate well with MasterCAM® machining software.

“Many of the products that we work with were originally developed using hand drawings,” notes Design Engineer Dan Kelly. “SOLIDWORKS gives us the tools that we need to document and improve design concepts, validate and prototype design performance, and manufacture and

assemble quality products.”

“Our challenge was not only to take great products and make them better, but also to streamline design and manufacturing to introduce innovative, high-quality products efficiently and cost-effectively,” Derus stresses. “We believe that SOLIDWORKS provides the best set of integrated tools for overcoming that challenge.”

Compressing Development and Manufacturing Fuels Growth

Since implementing SOLIDWORKS solutions in 2010, The Outdoor Group has introduced Elite bow models that have quickly set a new standard for quality, while reducing design cycles by as much as 50 percent. The company’s product development and marketing efforts have resulted in annual revenue growth of more than 30 percent.

“Our success stems from the ability to take the disparate pieces produced by our subsidiaries, then optimize them to manufacture premium products,” Derus says. “SOLIDWORKS has allowed us to reduce cycle times significantly, which saves time and money, while simultaneously improving the quality and shootability of our products.”