Conformal cooling channels, which uniformly cool injection molds and the plastic parts inside, have long represented the ultimate productivity goal in injection-molding manufacturing. Cooling channels that conform exactly to the geometry of the injection-molded part would make quick, uniform cooling of the molded plastic possible, resulting in better quality parts, faster cycle times, decreased part waste, and reduced energy consumption. To date, conformal cooling channels have remained just a research idea because the traditional techniques used to machine molds, such as milling and drilling, are incapable of producing all of the geometric shapes required. However, a team of researchers from Portland State University (PSU) and RapidMade, a 3D printing, manufacturing, and engineering company based in Portland, Oregon, have secured a federal grant to conduct research and development aimed at determining how to bring conformal cooling channels to the injection-molding industry. The research group of PSU student and Team Lead Christopher Mullens, PSU Computer Science Associate Professor Bart Massey, and RapidMade Engineering Director David Shapiro hope to leverage direct metal laser sintering and 3D metal printing manufacturing technologies to create molds with conformal cooling channels layer by layer. “The goal of this project is to develop a set of tools by modifying existing available tools to aid in designing and manufacturing conformal cooling channels for plastic injection mold cores,” Mullens explains. “With conformal cooling channels, quality issues related to nonuniform cooling would disappear, overall efficiency would go up, and per-part cycle times would be reduced.” While RapidMade is supplying the 3D metal printing and laser sintering services, the team needed a robust, integrated development platform for designing, simulating, and manufacturing mold cores with conformal cooling channels. The team chose SOLIDWORKS injection-molding solutions, including SOLIDWORKS Professional design, SOLIDWORKS Simulation Premium analysis, SOLIDWORKS Flow Simulation computational fluid dynamics (CFD) analysis, and SOLIDWORKS Plastics Premium injection-molding simulation and analysis software. “While I had experience using SOLIDWORKS and RapidMade uses SOLIDWORKS for its day-to-day business, we did look at other solutions, including Autodesk® Inventor® and Moldflow® software,” Mullens recalls. “We were most interested in how adaptable the solution is, and with SOLIDWORKS CAD, simulation, and plastics injection-molding tools, we found the right combination of capabilities to advance our research.”

Developing Workflow Path

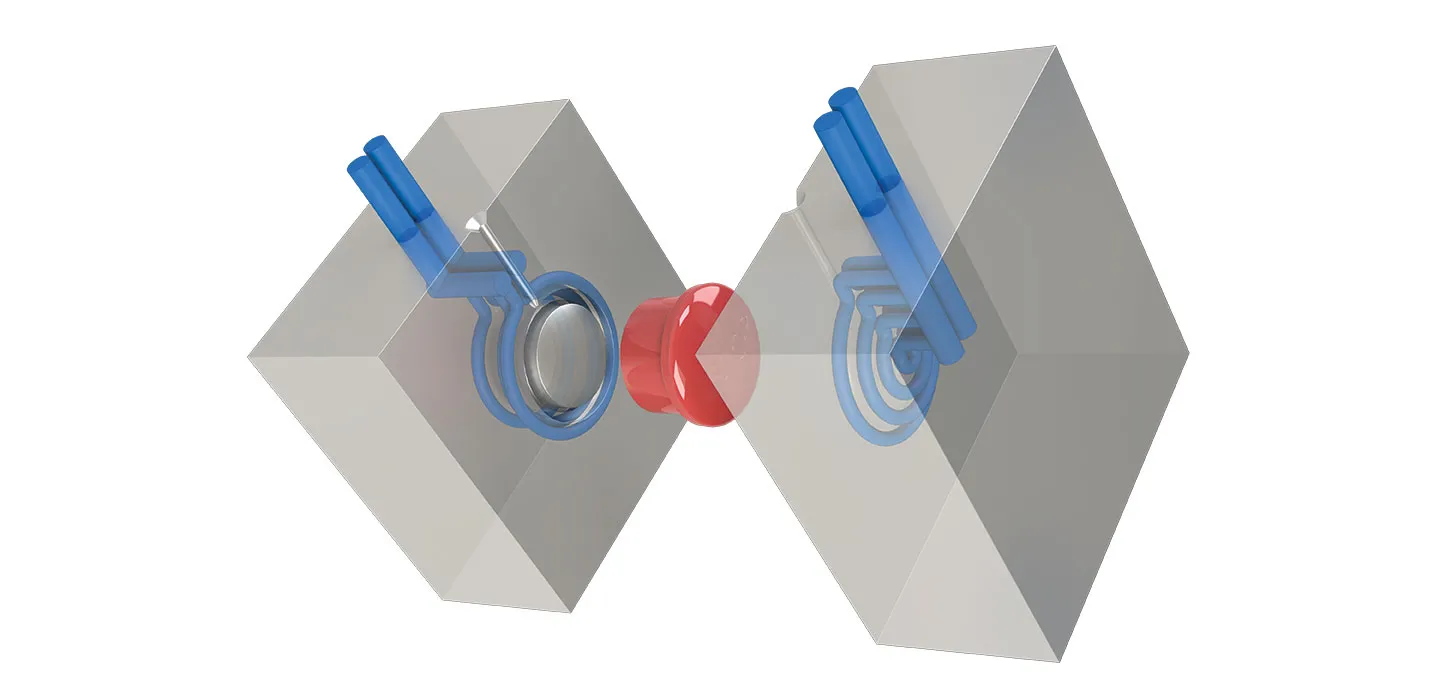

After conducting extensive research of the current state of the injection-molding industry, the RapidMade/PSU Research Team developed a workflow automation path for using SOLIDWORKS solutions to drive additive manufacturing techniques to create conformal plastic injection-mold cooling channels. The process begins with the creation of a plastic part, from which the mold and cooling channels are modeled using SOLIDWORKS Professional software. The design is then taken into SOLIDWORKS Plastics Premium to evaluate how molten plastic flows into the mold and to optimize the mold design with respect to material flow and cooling channel placement. SOLIDWORKS Flow Simulation is used to analyze how effectively the flow of liquid coolant in the cooling channels cools surrounding walls, and SOLIDWORKS Simulation Premium software supports analyses of the thermal effects of the cooling channels throughout the mold. Simulation findings help guide modifications and support design iterations.