Reduce Prototypes and Lead Times

S.G.A. used 3DEXPERIENCE Works Simulation to save time and money by minimizing the number of prototypes required to define the elastic properties of the elastomers used in the silent block on the connector arm bushing of the railway carriage for the Hitachi Caravaggio train car.

“The biggest savings we’ve experienced using 3DEXPERIENCE Works Simulation derive from the reduction in lead time between product design and final configuration and from the reduction in costs related to changes to production and control equipment,” Meli stresses. “Because 3DEXPERIENCE Works Simulation enables us to eliminate and/or minimize the number of prototypes required to achieve final product performance, it helps us to reduce lead time from design to final production as well as reduce both prototyping and fine-tuning costs.”

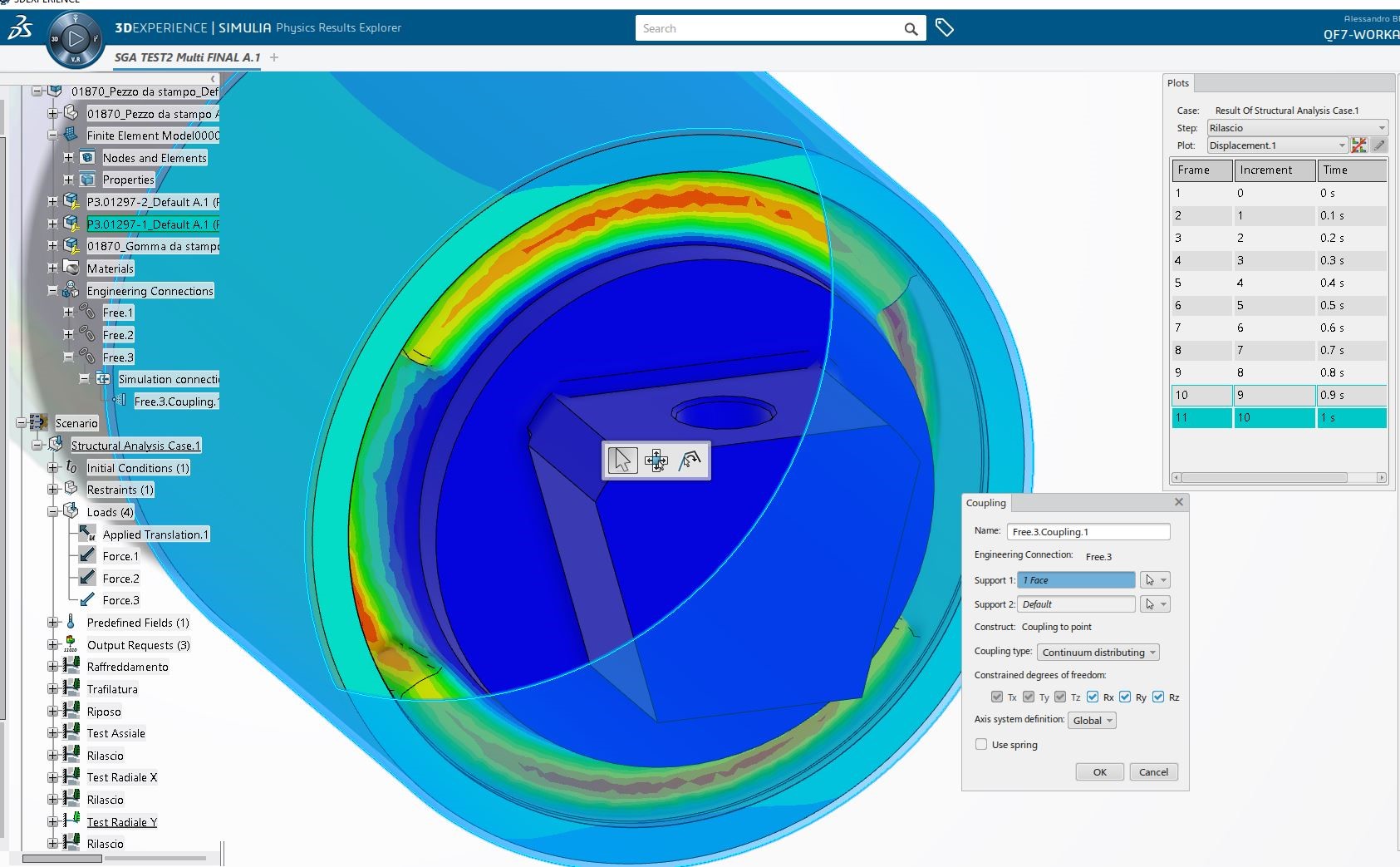

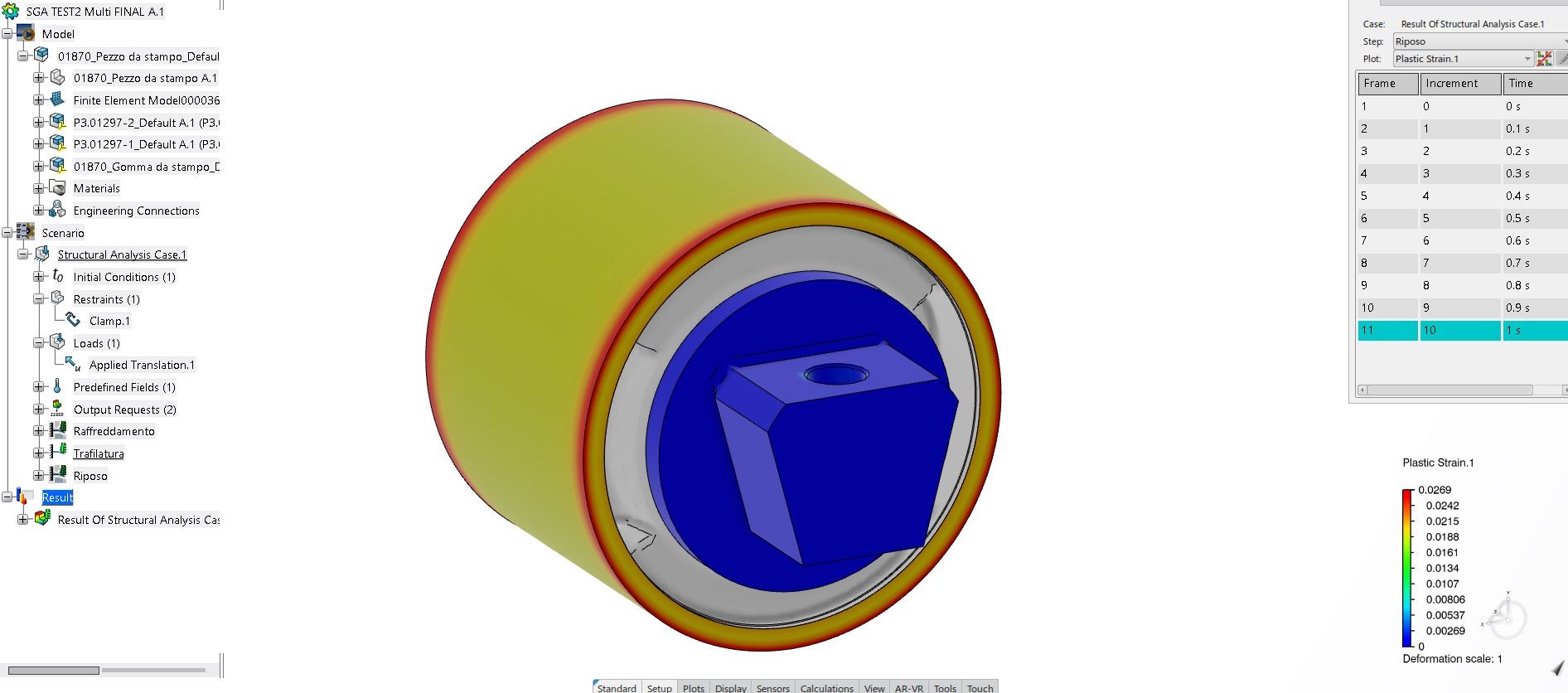

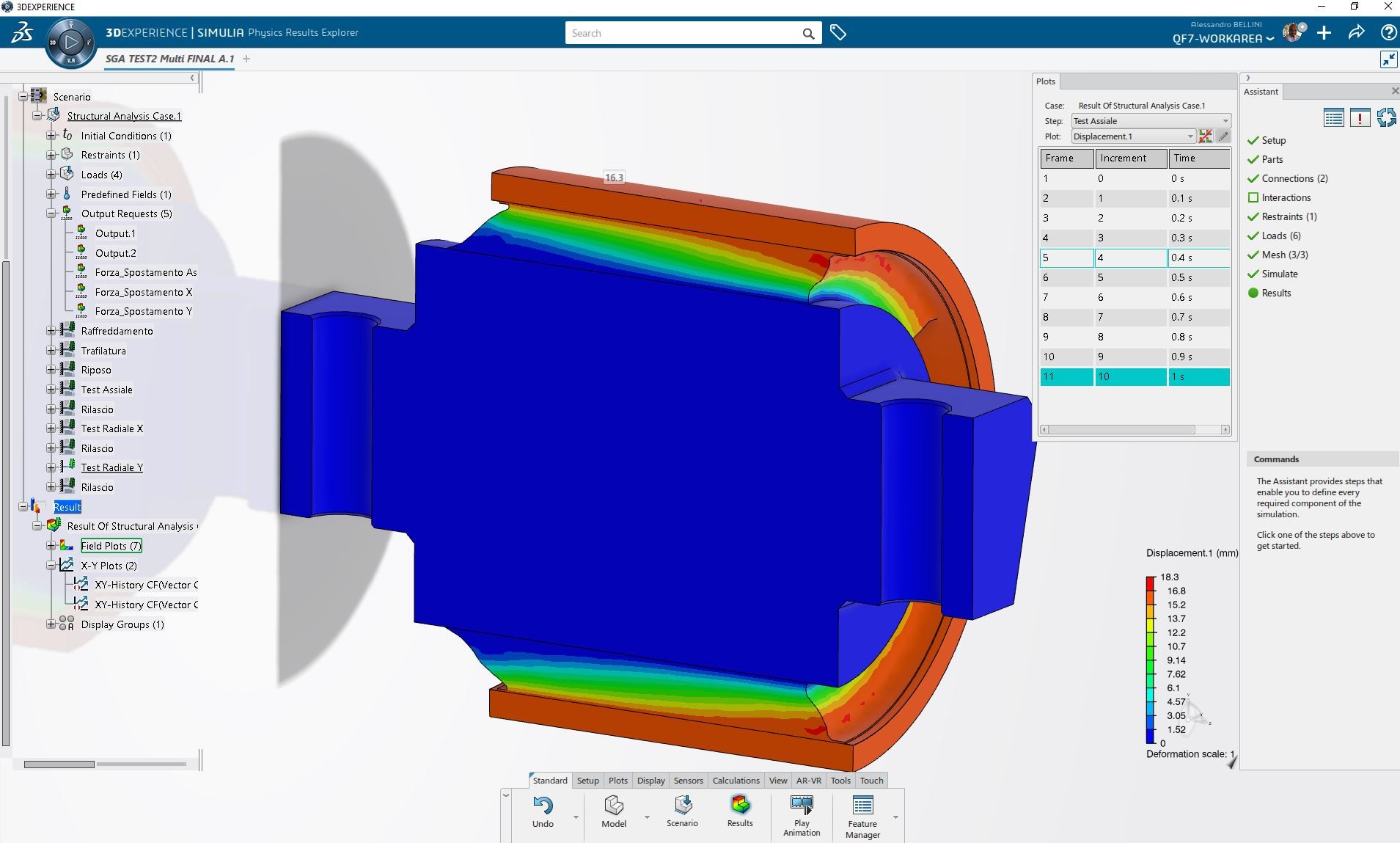

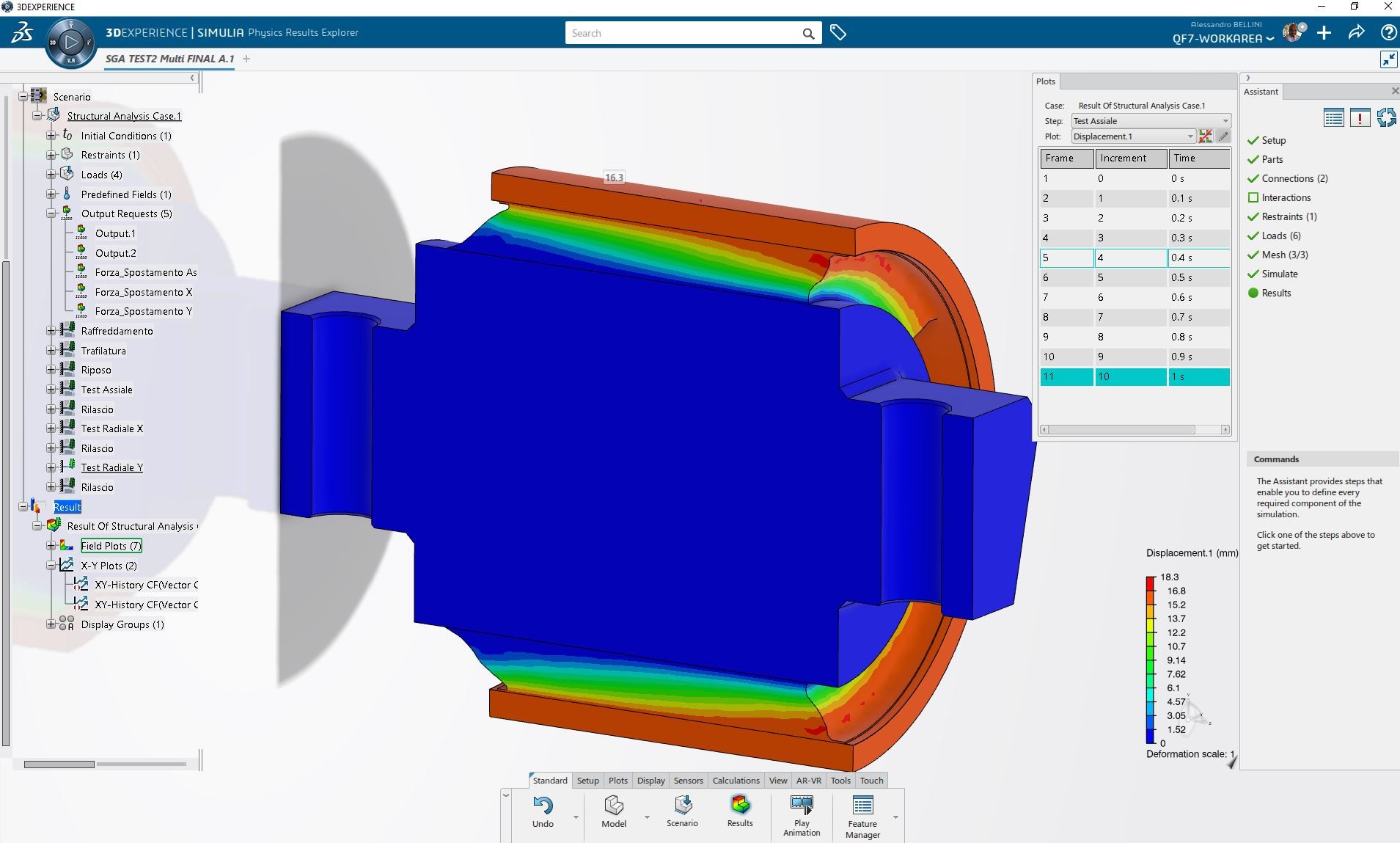

The majority of simulation scenarios encountered when developing anti-vibration systems involve large displacement analysis, but S.G.A. engineers also use 3DEXPERIENCE Works Simulation to achieve accurate results for many other challenging nonlinear, large displacement analysis problems.

The toughest issues involve the simulation of shrinkage/stress due to thermal variations and pre-compression due to steel plasticization. “With 3DEXPERIENCE Works Simulation, it is very easy to achieve results in line with the real results of a project that we had already finalized,” Massa adds. “In other words, we demonstrated the accuracy of the simulation results by validating an existing project with 3DEXPERIENCE Works Simulation.”

“3DEXPERIENCE Works Simulation gives us the full range of tools that we need to ensure that our products provide safe, reliable performance,” Meli says. “We also value the ability to conduct multistep/multiphysics simulations, such as performing thermal and mechanical analysis within the same project without having to duplicate geometry changes or create a new mesh due to the full integration between the SOLIDWORKS portfolio and 3DEXPERIENCE Works Simulation.”