Capt. Daniel Harper began using SOLIDWORKS design software to facilitate and actively take part in the design process, while managing complex builds as a professional boat captain. During that career, Harper gained an appreciation for all of the critical maintenance issues on a boat, including those that can lead to bigger problems in the future if they continue undetected. Minor issues, like a dead battery or shore power failure, can lead to substantial damage, such as when the water in the bilge gets too high because the bilge pump or switch fails to operate. Harper realized that if boat owners had a way to monitor boat systems from afar, they could detect and address all of the little things on a boat that can cause larger problems later if they are not immediately addressed. It was an idea that crystallized Harper’s vision of the Connected Boat™ and inspired him to found Siren Marine, the Rhode Island-based technology company that develops products for affordable, real-time monitoring and protection of boating assets. Born at sea and based on Harper’s deep boating experience, Siren Marine products include some of the most well-thought-out boat security systems on the market, allowing boat owners to use their smartphones, tablets, or computers to monitor and track their boat’s battery status, bilge level, temperature, location, course, speed, security, and engine metrics. Customers can track boat movements and even switch accessories on or off straight from the Siren app via wireless cellular technology. “As a captain, I managed a number of boat builds and wanted to be able to see the design as it progressed, so we modeled everything,” Harper, now founder and CEO of Siren Marine, recounts. “Over the years doing that, I purchased and learned how to use SOLIDWORKS mechanical design software. Even though I’m not a trained engineer, I know a lot about boats, and I found SOLIDWORKS to be a great tool for visualization and collaboration. When I decided to found Siren Marine and develop boat monitoring systems, I not only used SOLIDWORKS myself but also insisted that everyone with whom we work— from design to engineering to manufacturing partners—had to use SOLIDWORKS.”

COLLABORATION BETWEEN CAPTAIN, DESIGNER, AND ENGINEER

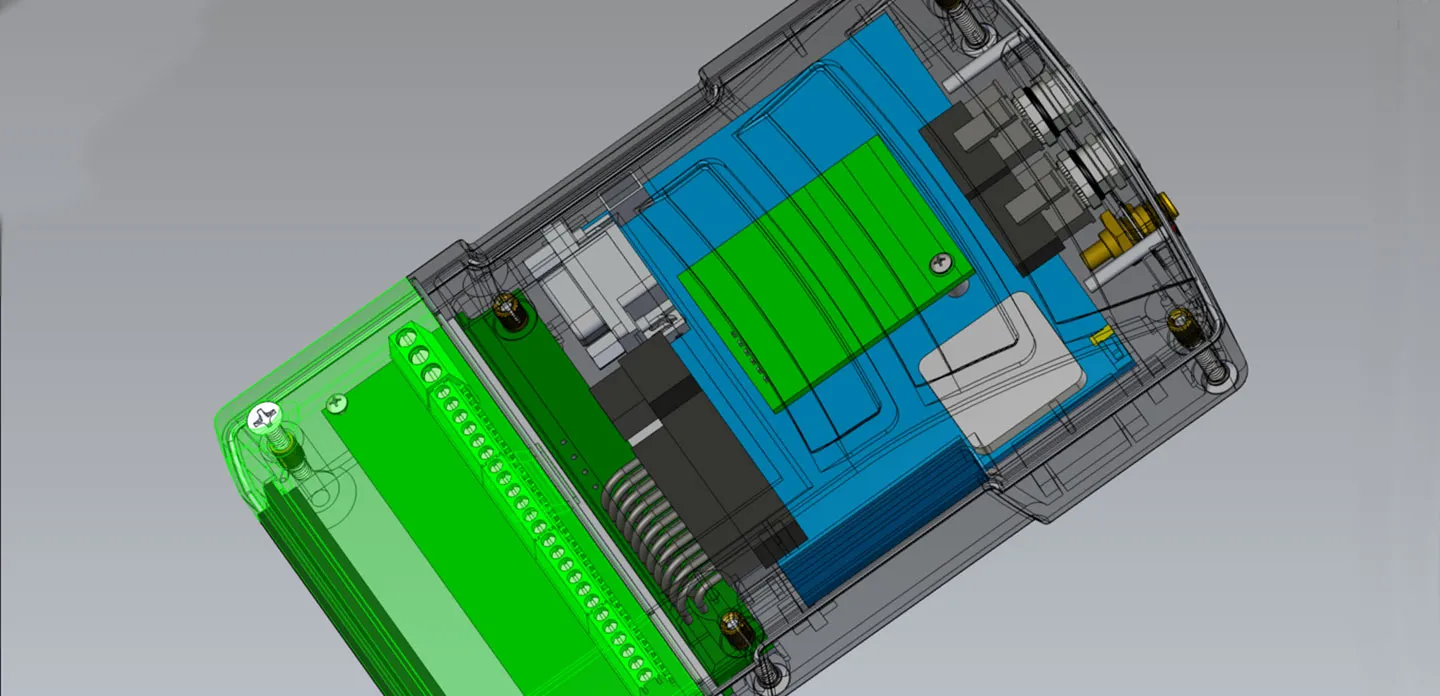

Siren Marine used SOLIDWORKS software to shorten the development cycle for its MTC (Monitor, Track, and Control) System by enabling Harper to collaborate with an industrial designer and mechanical engineer, both of whom used SOLIDWORKS Premium design software. The MTC is the most versatile and reliable system on the market, allowing customers to monitor important boat systems, track GPS position, establish geo-fences, and remotely control lighting, air conditioning, security, and other systems with a smartphone and the Siren app. “SOLIDWORKS is critical to the way we handle development,” Harper stresses. “Because I have the boating knowledge and my collaborators understand mechanical design, SOLIDWORKS serves as the conduit for bringing both types of expertise together to create the best products that we can. With SOLIDWORKS, I can review each design iteration, offer input, and make important design and manufacturing decisions in real time, which shortens the development process.”