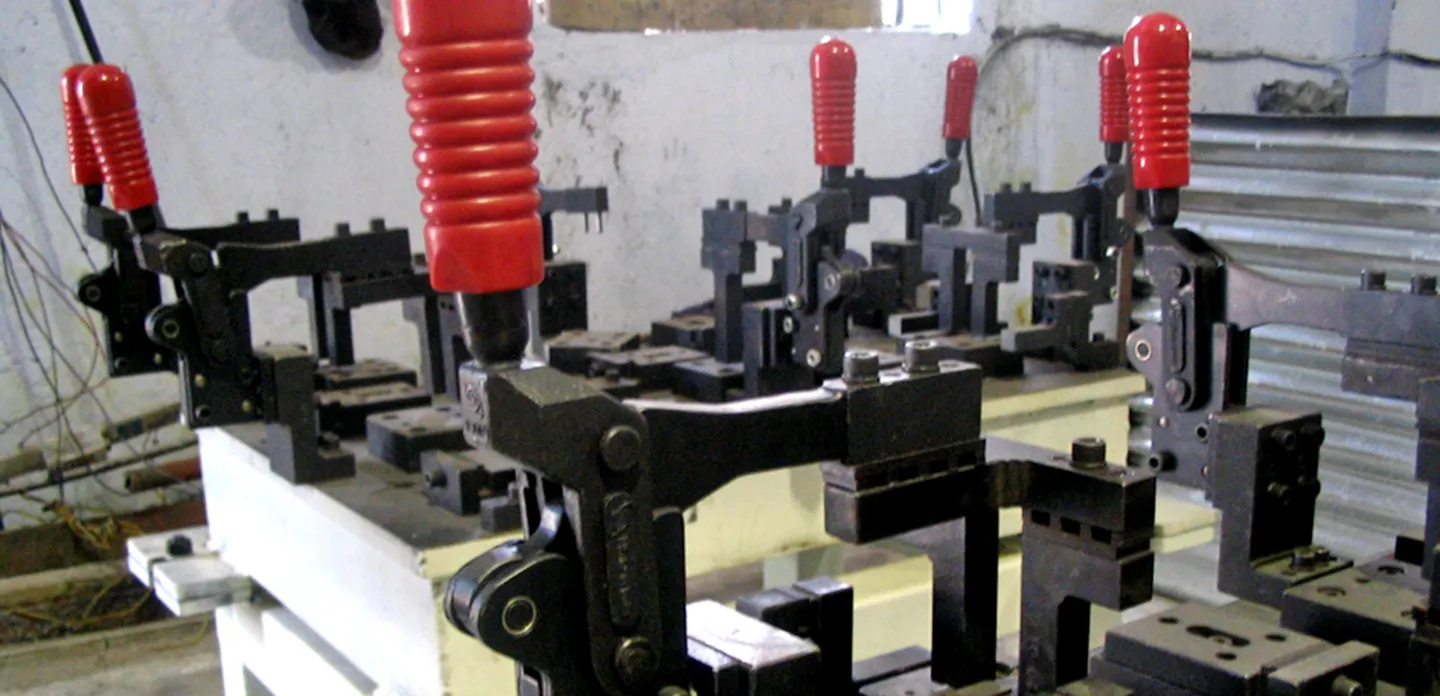

Steel-Smith is the largest manufacturer of toggle clamps and clamping solutions in India. The company pioneered the development of toggle clamps in India 40 years ago and produces the country’s broadest and most widely recognized line of these useful, adaptable tools, which serve a range of applications requiring different shapes, sizes, and holding capacities.

Since its inception, Steel-Smith has striven to continuously improve product quality and introduce innovative, effective clamping solutions. The toggle clamp manufacturer’s focus on product development has enabled Steel-Smith to grow from a small setup consulting firm to become India’s largest manufacturer and exporter of toggle clamps and other industrial accessories.

Steel-Smith’s success rests on its commitment to leveraging the latest product development technologies to overcome challenges related to product design, innovation, and productivity. In 2012, the company decided to re-evaluate its use of AutoCAD® 2D and Solid Edge® 3D design tools. According to Design Manager Ravi Panchal, Steel-Smith wanted to identify a new 3D solution that would help the company improve design accuracy, reduce development time, and enhance design communications.

“We believed moving to 3D would enable us to accelerate time-to-market,” Panchal explains. “However, our initial attempt to use Solid Edge 3D design software didn’t succeed, and we became dissatisfied with the level of support that we received. That experience led us to evaluate other 3D design solutions.”

After evaluating available 3D design packages, Steel-Smith standardized on SOLIDWORKS Professional design software and utilizes eDrawings® for Android™ and SOLIDWORKS Solution Partner software Modo® for SOLIDWORKS add-on applications. The company chose SOLIDWORKS because it’s easy to learn and use; provides effective sheet metal, interference detection, and design configuration tools; includes PhotoView 360 rendering and eDrawings communication tools; and receives the strong support of SOLIDWORKS reseller Addonix Technologies.

“We were convinced that SOLIDWORKS would not only allow us to smoothly transition from 2D to 3D, but also enable us to achieve our productivity and customer satisfaction objectives,” Panchal recalls. “Clearly, we made the right choice because we have realized substantial productivity gains in the design, marketing, and communication of our products.”

FASTER DESIGN EXPANDS PRODUCT LINE, SHORTENS TIME-TO-MARKET

Since implementing SOLIDWORKS Professional software, Steel-Smith has realized efficiency improvements in all facets of development, including a 50 percent reduction in design cycles, a 40 percent drop in development costs, and a 40 percent decrease in time-to-market. These greater efficiencies have resulted in a dramatic expansion in the company’s product offering: from roughly 200 to more than 500 products.

“SOLIDWORKS is a very beneficial and timesaving design solution,” Panchal stresses. “About 60 percent of our toggle clamps include sheet metal components. Creating flat patterns in SOLIDWORKS saves time, as does the ability to use design configurations to create entire families of parts and assemblies. We also benefit from improved visualization by eliminating interferences and quickly determining weight and surface area for coating and manufacturing. SOLIDWORKS allows us to reduce development and product lead-times, as well as reduce the time required for research and development.”