When the ESTCube-1 satellite blasted into space atop a European Space Agency (ESA) Vega rocket on May 7, 2013,

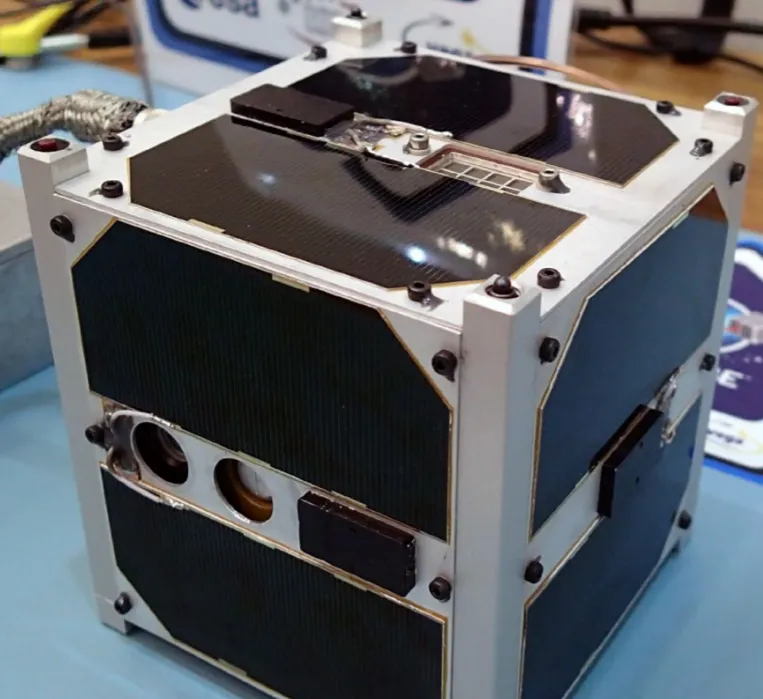

it was the first Estonian-built satellite to enter Earth’s orbit. The tiny 10 centimeter by 10 centimeter by 10 centimeter, 1.05 kilogram satellite was built as part of the Estonian Student Satellite Program to perform proof-of-concept testing of the electric solar wind sail.

A team of students from Tallinn University of Technology, Tartu University, the Estonian Aviation Academy, and the University of Life Sciences undertook the challenge of designing and building a small satellite to carry a payload to test electric solar wind sail deployment. Invented at the Finnish Meteorological Institute in Finland by Pekka Janhunen, the electric solar wind sail uses a system of electrically charged wires that act as tethers when deployed to form a sail. Given a negative charge by an electron gun, the tethers are repelled by the positively charged protons in the solar wind, propelling spacecraft at speeds of up to 30 meters per second. The system has the potential for the development of faster,

less fuel-intensive space propulsion systems.

According to ESTCube Structure and Mechanics Subsystem Manager Paul Liias, a mechanical engineering master’s degree student at Tallinn University of Technology, the team needed

an effective 3D design platform for developing the satellite and collaborating with manufacturing and payload partners. Prior to joining the ESTCube project in 2008, Liias had a choice of using SOLIDWORKS® Education Edition or Solid Edge® software for his Tallinn University of Technology product

development courses.

“Growing up, I always had an interest in aerospace, which is why I was eager to join the ESTCube project,” Liias recalls.

“I knew SOLIDWORKS software came from Dassault Systèmes, developer of CATIA® software, which is the best-known design tool for aerospace development. I also wanted to start with

a CAD program with a good interface that is easy to use,

so I chose SOLIDWORKS.

“When we needed a CAD platform for the ESTCube project, SOLIDWORKS was the obvious choice,” Liias adds. “Not only was SOLIDWORKS my preferred design solution, it was also what the students at Tartu University used. We did a lot of collaborating on this project, and SOLIDWORKS provided important advantages.”

Developing Satellite Assembly

Using SOLIDWORKS Education Edition software, the student team developed all the CAD models and production drawings for the ESTCube-1 satellite. “SOLIDWORKS was the right choice for this project because in many ways we were learning while doing,” Liias explains. “Since we were learning how to design, manufacture, and assemble a satellite to carry the electric solar wind sail payload, we needed a development platform that was easy to learn and use, and that wouldn’t impede our progress.

“With the entire student team working in SOLIDWORKS, we developed individual part files as part of smaller assemblies, and then combined them to complete the whole assembly,” Liias continues. “SOLIDWORKS helped us streamline the exchange of part and assembly models within the student team, as well as with payload and manufacturing partners.”