Design a Robot in One Month

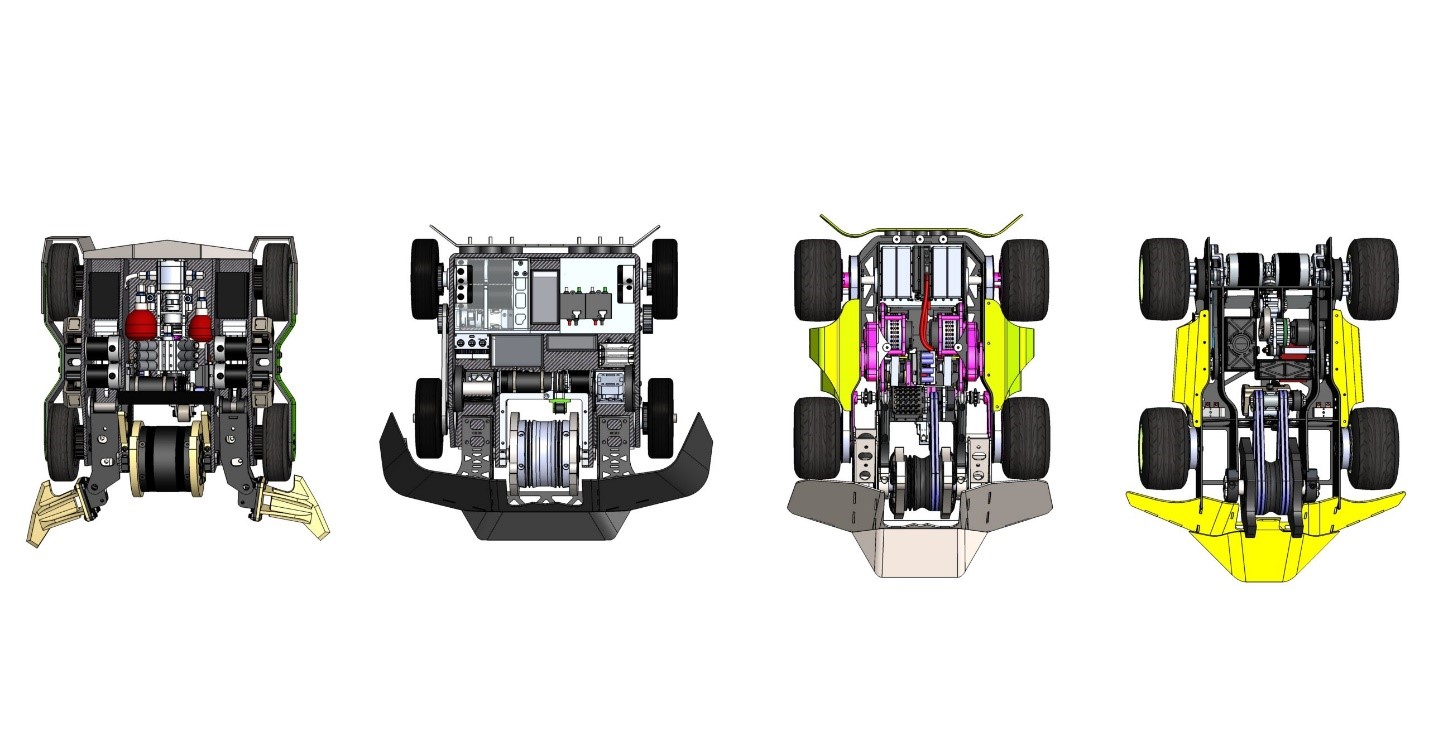

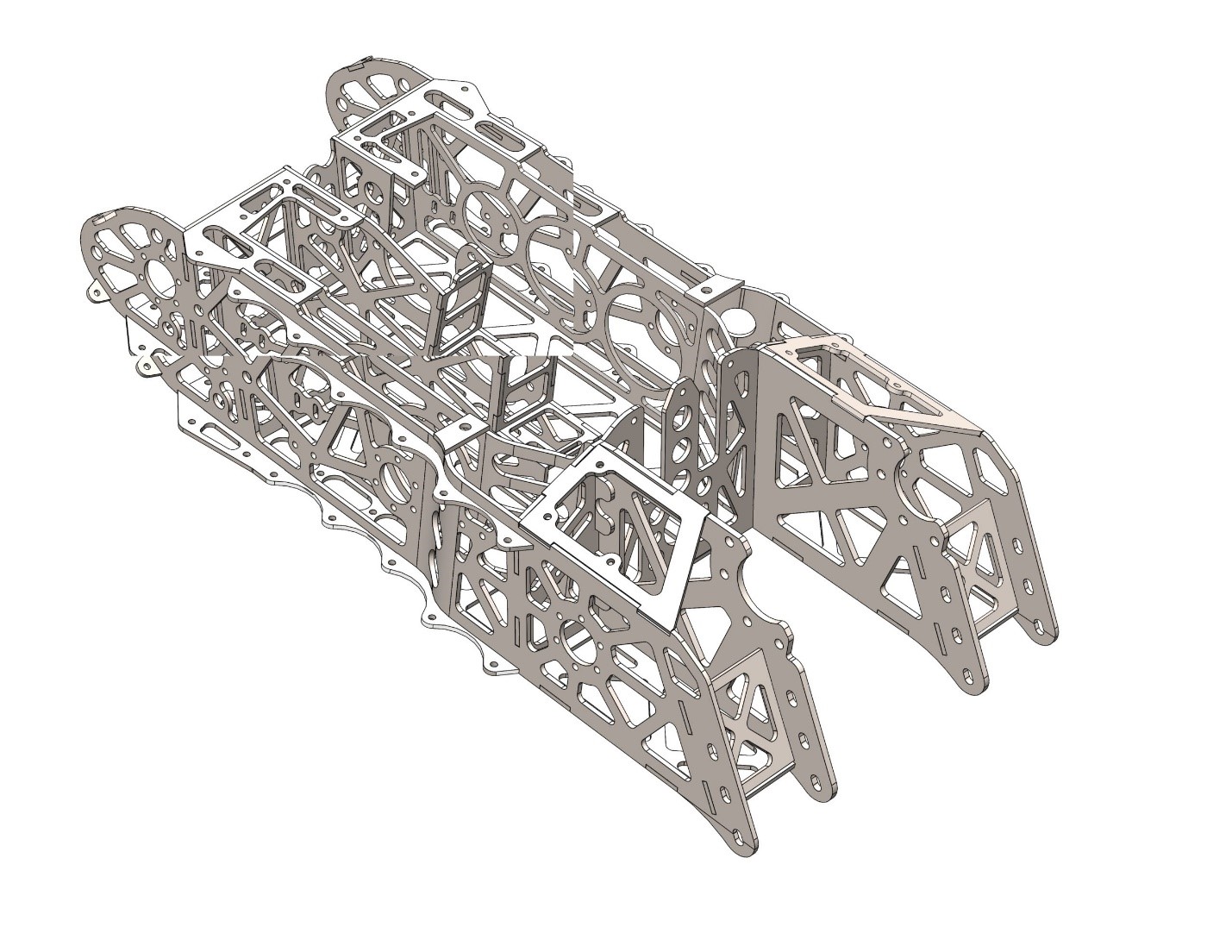

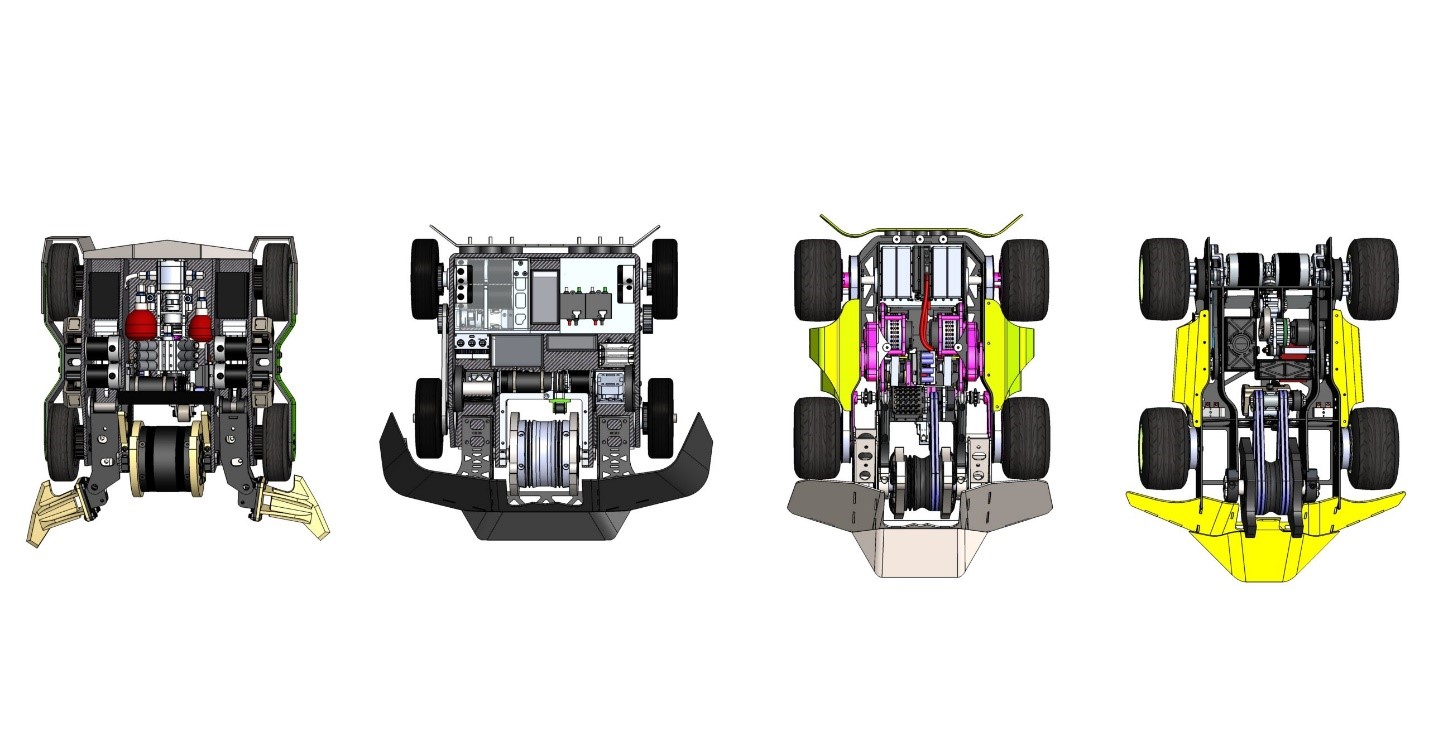

The BattleBots schedule allows teams roughly one month to complete the design work to meet production deadlines. Under time pressure to build the first HyperShock robot (each year’s rendition has been a different version of a vertical disc spinner), Bales knew the team needed to use the SOLIDWORKS® design platform. “I had been using SOLIDWORKS for a long time—ever since I learned how to use the software in middle school—and still use the software in my day job at Syntheon,” Bales recounts.

“It was a no-brainer to use SOLIDWORKS because it lets us iterate and communicate efficiently,” Bales stresses. “Since building the first HyperShock robot, we’ve been fortunate in obtaining a SOLIDWORKS sponsorship, which provides additional simulation and visualization tools that are accelerating our robot development efforts.”

“Every version of the HyperShock robot has been designed in SOLIDWORKS,” Bales continues. “In addition to the design speed that we have realized using the software, SOLIDWORKS is truly an industry standard data format that our vendors and suppliers work with regularly, which helps to minimize delays in production and assembly.”