Amscreen Delivers Digital Intelligence to Connect Urban Communities

Digital hardware manufacturer leverages SOLIDWORKS Simulation to test every aspect of a design—heat, flow, and stress—before committing to physical tooling.

Challenge

Design the smartest digital free-standing signage that collects real-time environmental and traffic information, while providing high-quality visual advertisements that generate revenue in any urban area.

Solution

Design new products from concept through final production using SOLIDWORKS® Design and Simulation tools, which leverage the Internet of Things, are easy to ship, and have a very low carbon footprint.

Results

- Develop high-end products from concept to delivery

- Virtually simulate prototypes before production

- Quickly adjust design concepts to share with clients

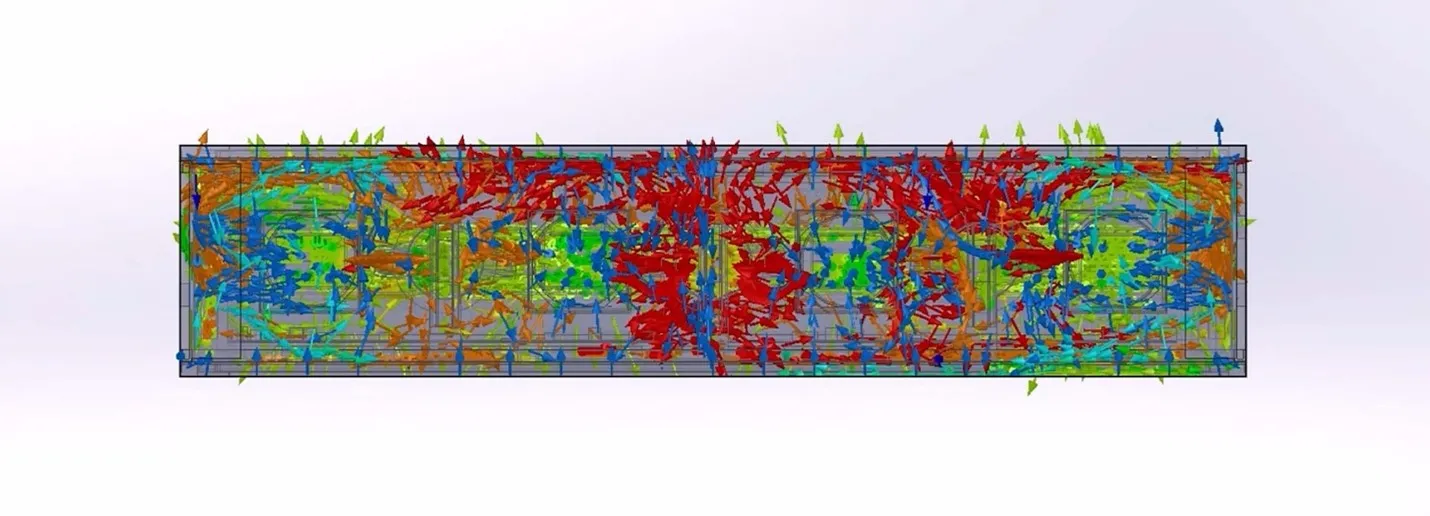

- Easily compute computational fluid dynamics (CFD) to model heating and cooling systems

With over 6,500 digital screens in 15 different European markets, Amscreen is one of Europe's biggest manufacturers of digital outdoor signage products. Since its inception in 2007, Amscreen has focused on innovation that has fostered huge growth.

The company offers digital billboards along with kiosks, bus shelters, free-standing, and wall-mounted signage, with innovative escalator, underground, and full-wrap bus shelter signage in the works. Amscreen’s smart digital signage collects real-time environmental and traffic information, up to 250 data points, including foot and motor vehicle traffic, noise levels, and air quality. At the same time, the signs display digital ads, giving cities a way to generate revenue while passively monitoring urban conditions.

The lightweight, easy-to-ship, low-carbon-footprint products leverage the Internet of Things with individual street-level hubs linked across a connected network. Each screen is created and constantly monitored from Amscreen headquarters in Bolton, in north-west England. Amscreen’s patented real-time remote device management (RDM®) guarantees uptime and longevity.

Quick Conceptualization and Delivery

Quick Conceptualization and Delivery

Amscreen’s growth is attributed to its innovation and rapid delivery of bespoke signage and street furniture. The company’s products are customizable to any size, space, specification, and environment.

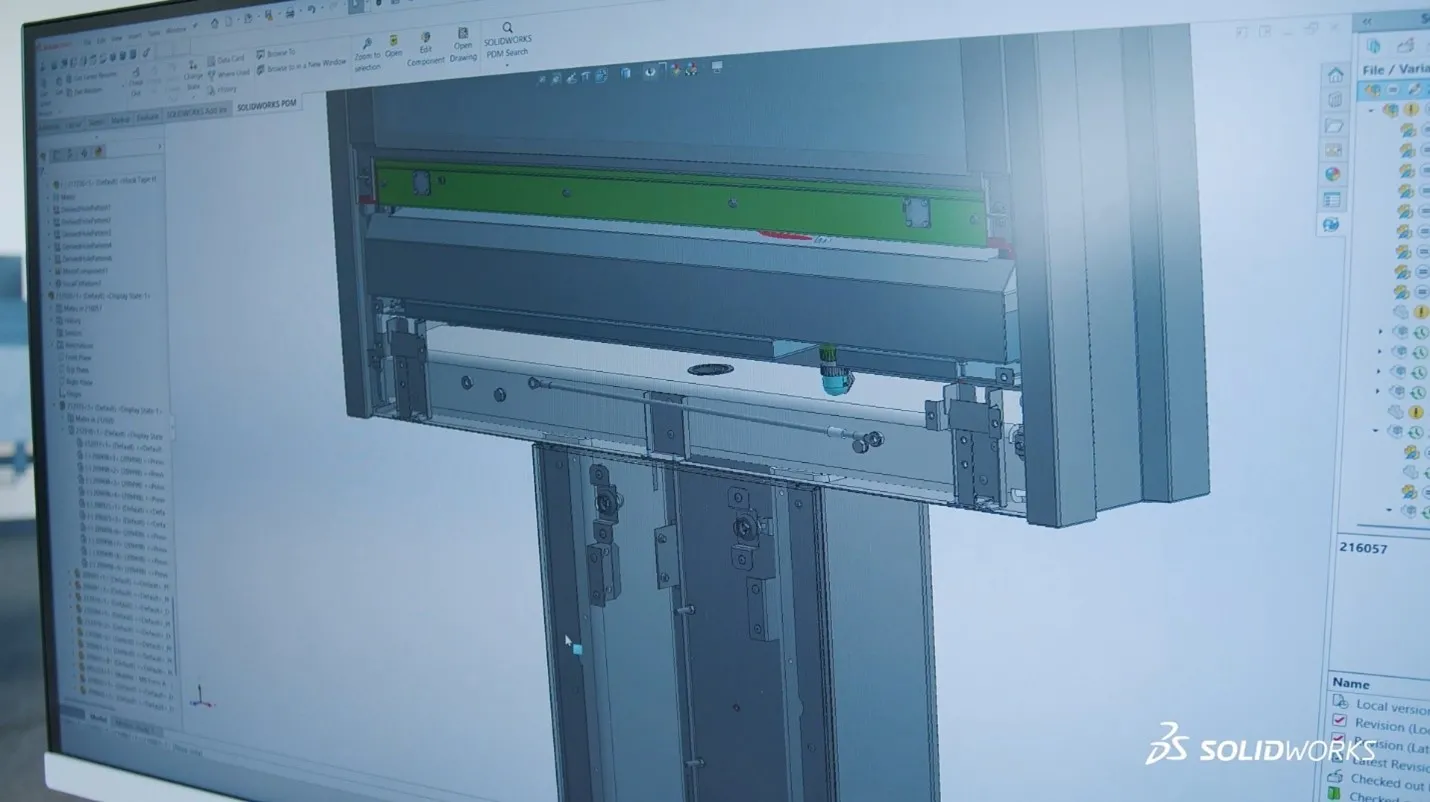

Amscreen uses SOLIDWORKS® from the earliest stages of a new concept. “We'll draw up some initial concepts very quickly and discuss them with the client. We then use SOLIDWORKS all the way through the prototype design, through to the detailed design,” says Amscreen CTO David Edgar. “Using SOLIDWORKS and simulation tools, we are creating some really quite radical new ideas that will allow us to improve our carbon footprint.

Related Resources

Before we even start to commit to any kind of tooling, we want to have a complete 3D model of our entire system, including the heat transfer, the fluid flow, the mechanical stress analysis—and SOLIDWORKS allows us to integrate all of those together seamlessly.

Designing for Durability and Sustainability

Amscreen leverages SOLIDWORKS Simulation to ensure that signage products withstand heavy loads while maintaining a low carbon footprint. The company also uses computational fluid dynamics (CFD) to model the heating and cooling systems critical to sign longevity in diverse outdoor temperature extremes from Finland to Spain. Mechanical engineer Stephen Slattery notes, “The calculations behind CFD are incredibly time consuming and complex to do by hand. We can leave SOLIDWORKS running overnight and then come back the next day and we've got five different fan sizes.”

Because SOLIDWORKS Simulation has played a key role in reducing the carbon footprint of Amscreen products, which the company regards as central to its success, Egar notes, “SOLIDWORKS is an absolutely critical part of our design operation.”

Laying the Digital Foundation

For data migration to a new ERP system, Amscreen leveraged SOLIDWORKS PDM for speed and efficiency. “PDM has been fantastic because I can modify data to suit our new system on a large scale. I can get a bunch of assemblies, a bunch of parts, and convert part numbers, descriptions, and product groups, basically all in one go, whereas normally we'd have to go through each part,” enthuses Mechanical engineer Stephen Slattery.

Amscreen is moving towards a design philosophy that involves a digital twin. “Before we even start to commit to any kind of tooling, we want to have a complete 3D model of our entire system, including the heat transfer, the fluid flow, the mechanical stress analysis—and SOLIDWORKS allows us to integrate all of those together seamlessly,” stresses Edgar.

He concludes, “The tools we use within SOLIDWORKS are extremely advanced now, and we require support from time to time. Having a partner like SOLIDWORKS … has been a great help to us.”

Products:

- SOLIDWORKS Standard

- SOLIDWORKS Simulation Professional

- 3DEXPERIENCE Platform

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.