DLV Technologies Advances Offshore Survey Engineering

Offshore and subsea equipment manufacturer uses SOLIDWORKS and the 3DEXPERIENCE platform to accelerate development, improve reliability, and strengthen client collaboration.

Challenge

Engineer safer, more predictable offshore survey and subsea geotechnical equipment capable of withstanding demanding pull forces, deck loads, and underwater conditions.

Solution

SOLIDWORKS® Design, SOLIDWORKS Simulation, and 3DEXPERIENCE® for modeling, validating, visualizing, and managing the data of equipment development.

Results

- Improved ability to pinpoint structural stresses and optimize designs

- Stronger client confidence via detailed 3D visualizations

- Faster design iterations backed by cloud-based data management

- Streamlined efficiency with training and technical support

Far from shore, where vessels pitch unpredictably and the seabed is anything but uniform, critical offshore work depends on equipment most people never see and engineering most never think about. Before an oil rig is installed or a wind turbine is anchored, subsea geotechnical work has to prove the seabed can safely support it.

Meeting that requirement safely and repeatably is far from trivial. That challenge led Design Engineer David Crowe to build his business around offshore survey and subsea geotechnical operations. “DLV Technologies was set up in 2024 with a focus as an engineering company and turnkey solution provider targeting the offshore survey industry, says Crowe." DLV’s approach centralizes design, analysis, and fabrication under one roof, giving customers a faster, more accountable path from concept to offshore-ready equipment.

Startup Growth Powered by Proven Engineering Tools

With a new business to build and clients expecting rapid design cycles, transparent communication, and clear demonstrations of structural integrity, DLV Technologies needed tools that could handle engineering depth with a strong ability to show clients at varying levels of engineering expertise why the products would be successful. Crowe wanted his clients to clearly see how and why the designs would perform safely offshore.

Related Resources

When I set up DLV Technologies, SOLIDWORKS was always going to be one of my favorite choices; it is one of the most popular tools used globally.

Crowe knew from day one which platform would anchor his company’s engineering workflow: “When I set up DLV Technologies, SOLIDWORKS was always going to be one of my favorite choices; it is one of the most popular tools used globally.” To support the UK company’s rapid growth, Crowe joined the SOLIDWORKS for Startups program to gain access to the 3DEXPERIENCE platform for design traceability, secure data management, and collaboration.

Simulation-Driven Validation for Offshore Reliability and Safety

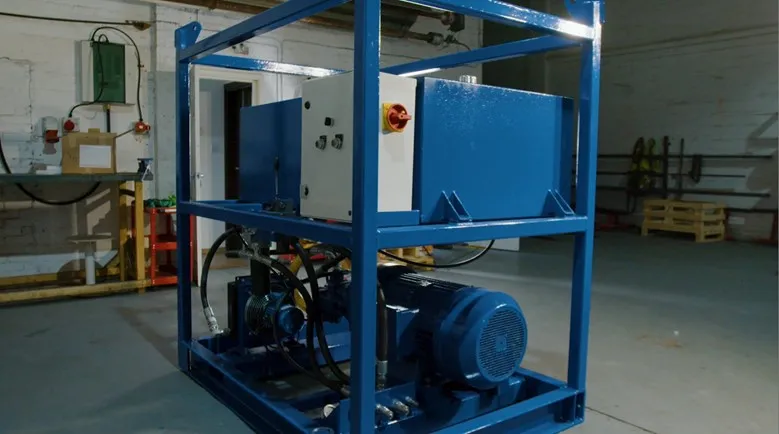

As the company began developing its equipment portfolio, SOLIDWORKS Design, SOLIDWORKS Simulation, and the 3DEXPERIENCE platform became the foundation of every project. All design, engineering, and fabrication work is done onsite at DLV Technologies. This end-to-end control provides a major advantage because it eliminates hand-offs amongst multiple contractors, speeds turnaround, reduces errors, and ensures every component is built to the same high standard. And that discipline on the engineering side extends directly into how DLV keeps clients aligned with the design.

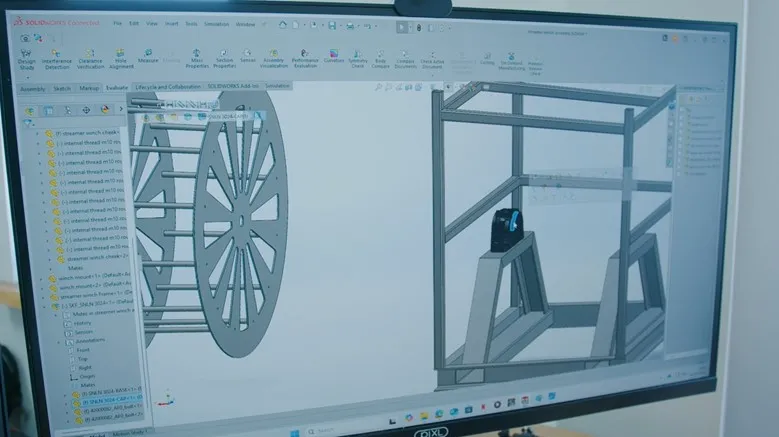

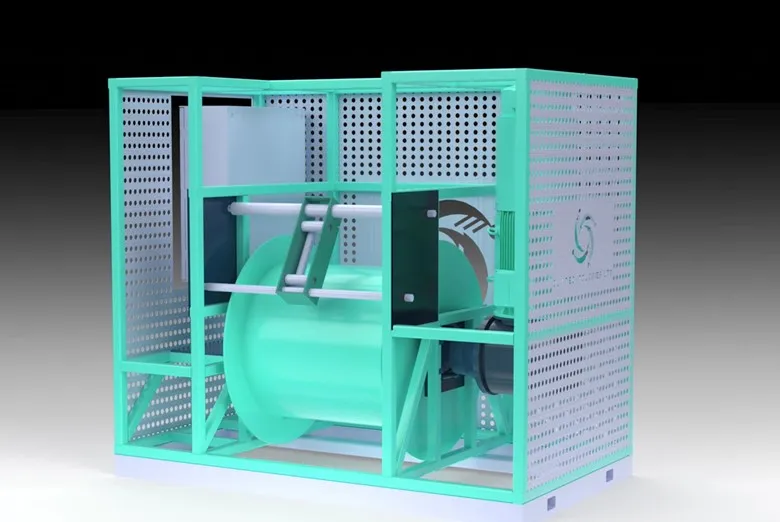

Effective client communication depends heavily on a clear understanding of the product. To that end, Crowe relies on detailed 3D imagery created directly from SOLIDWORKS models. “It's a huge help being able to provide detailed 3D images to clients so they can clearly see what they are going to get.” When clients can see DLV’s SOLIDWORKS designs with engineering-level clarity, collaboration becomes more efficient and decisions happen faster, keeping every iteration moving forward with confidence.

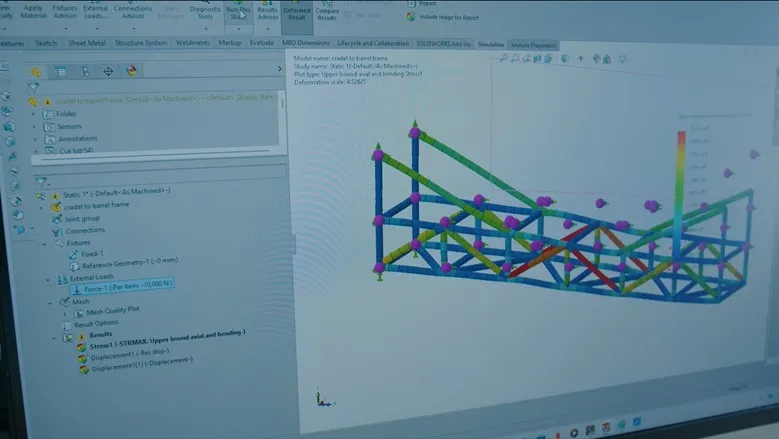

Once modeled, the equipment is validated using SOLIDWORKS Simulation to ensure it will withstand offshore forces. Crowe emphasizes how crucial this is: “Having these tools to visualize the pull forces, the deck forces, the structural integrity and bend moments of the designs … I can target exactly within the structure where these pull forces are coming from and how that's impacting the equipment.”

Building Trust via Engineering Data

DLV Technologies’ use of SOLIDWORKS Design, SOLIDWORKS Simulation, and the 3DEXPERIENCE platform has enabled the company to operate with the rigor and responsiveness expected in offshore engineering while ensuring clients receive the data-driven clarity they need to make sound final decisions.

The combined workflow enables rapid iteration, structural validation, professional visualization, and secure, accessible design data, all essential for a small engineering firm competing in a demanding industry. “I would a hundred percent recommend using SOLIDWORKS,” notes Crowe. SOLIDWORKS’ visualization capabilities also turned out to be an important part of business development for DLV Technologies. “SOLIDWORKS Visualize is probably one of my favorite features because it brings the designs to life and helped win various projects,” enthuses Crowe.

Products:

- SOLIDWORKS Design

- SOLIDWORKS Simulation Premium

- SOLIDWORKS Visualize

- 3DEXPERIENCE Platform

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.