Frangus Engineers the Future of Rail Design

From advanced 3D modeling and PLC schematics to high-end 3D visualizations, rail design consultancy leverages SOLIDWORKS to engineer high-performance rail systems./customer-story/

Challenge

Solving the most complex engineering challenges for the European rail and construction industry. Designing Rail industry products from high-speed trains and trams to signaling, rail infrastructure, and digital control systems that meet strict European standards and regulations,

Solution

Minimize costly physical testing using SOLIDWORKS Simulation, and create fully detailed drawings generated directly from SOLIDWORKS 3D CAD models to ensure a flawless fit and finish during assembly and fabrication. Generate very complex schematics needed for the PLC control system and produce those as 3D models using SOLIDWORKS Electrical.

Results

- Reduced time to market by virtual testing designs

- Shortened electrical design cycles

- Reduced revisions and rework

- Ensured flawless fit in final production

Frangus LTD is the brainchild of engineer David Thompson and his wife. The couple began their journey in the United Kingdom in 2001 by specializing in manufacturing equipment for the rail industry as Thompson Engineering Design LTD. After selling the manufacturing arm in 2013, they founded Frangus, a design consultancy dedicated to solving complex engineering challenges for rail and construction clients.

Europe’s rail industry is an expansive ecosystem of OEMs, suppliers, and engineering service firms designing everything from high-speed trains and trams to signaling, rail infrastructure, and digital control systems. European standards and regulations must be strictly adhered to at every juncture in the product development process.

Frangus meets these challenges using state-of-the-art technologies for design and manufacturing within an integrated product development workflow.

Full Steam Ahead

In 2001, the Thompsons recognized that 2D CAD was hindering the company's progress. “We looked around for a solution and invested in SOLIDWORKS in 2002,” recalls Thompson. The move was transformative. What began as a 3D modeling upgrade quickly evolved into a fully integrated design ecosystem with SOLIDWORKS Premium, SOLIDWORKS Simulation Professional, SOLIDWORKS Electrical Professional, and SOLIDWORKS Composer.

Frangus continues to explore new capabilities such as electromagnetics to further expand its service offering. “Over the 23 years we've been using SOLIDWORKS, it's been the mainstay of our business, without a doubt. Key to the success of SOLIDWORKS is not only the quality of the product, but the support we get [from SOLIDWORKS reseller Innova Systems].”

Related Resources

Riding the Rails of Modern Design

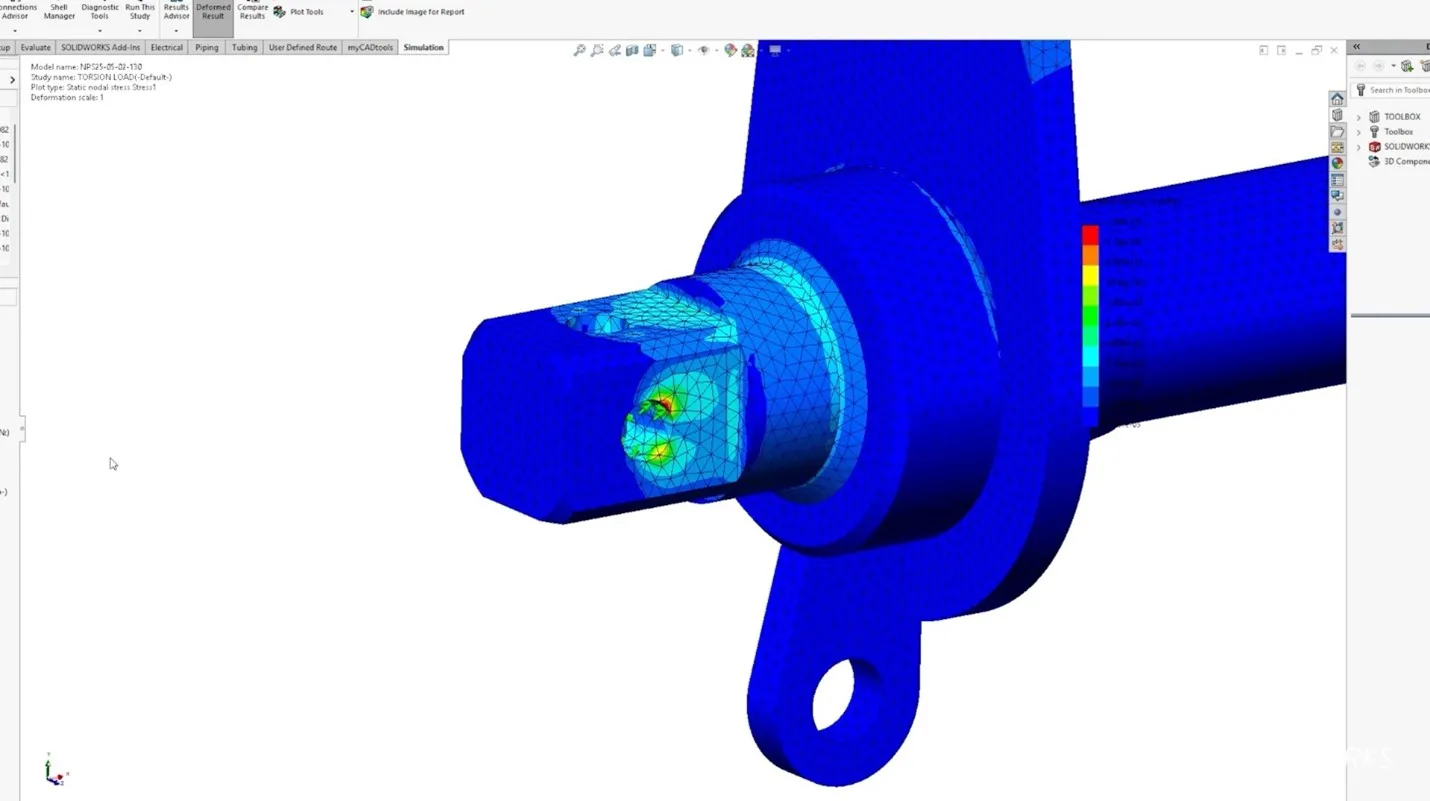

SOLIDWORKS advanced 3D modeling is leveraged to define every part, tolerance, and material property, ensuring Frangus designs are accurate and manufacturable. Virtual prototyping using SOLIDWORKS’ finite element analysis, tolerance stack analysis, and motion studies tools minimize costly physical testing. Fully detailed drawings, generated directly from SOLIDWORKS 3D CAD models, ensure flawless fit and finish during assembly and fabrication. SOLIDWORKS enables Frangus engineers to produce high-quality renderings and animations that bring concepts to life for marketing and customer presentations.

The company’s comprehensive workflow, with every tool and project management in the same integrated environment, reduces rework, improves communication between teams, and ensures designs pass inspection the first time. Thompson continues, “The ability to visualize products in 3D, to render them in 3D, to provide good marketing materials, but also to animate them means that we as engineers can communicate with our clients so much better.” The 3D visualizations from SOLIDWORKS reduce misunderstandings and ensure everyone shares the same mental model of the final design.

SOLIDWORKS Simulation informs each design choice of every Frangus project. Once the design is validated virtually, engineers use SOLIDWORKS Composer to prepare documentation with each assembly and weldment clearly detailed for production. Production and assembly teams use SOLIDWORKS eDrawings to examine parts and assemblies up close to improve accuracy and efficiency on the shop floor.

Making Tracks. Literally.

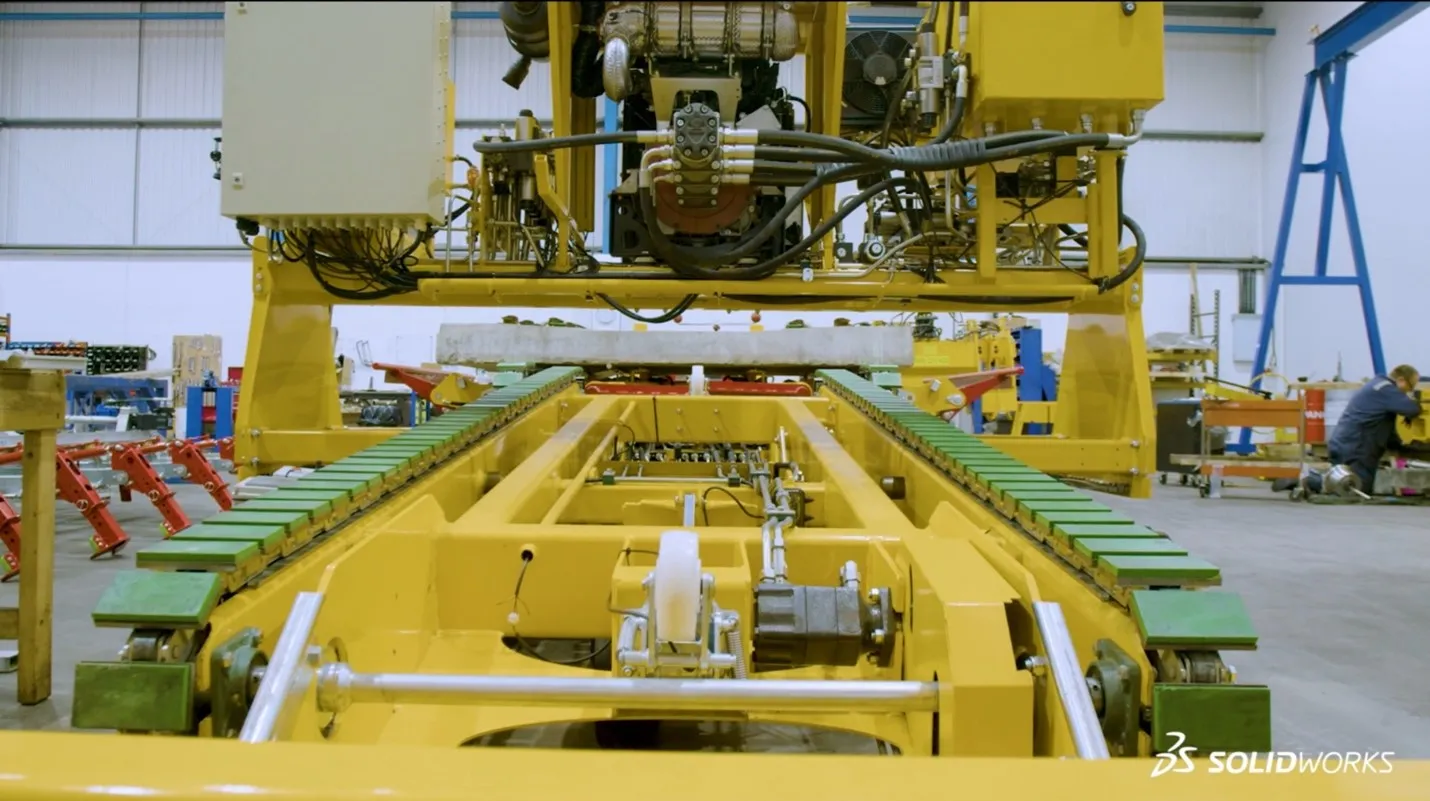

One notable example of the value of SOLIDWORKS’ integrated tools is Frangus’ high-output sleeper layer that is capable of installing up to 1,000 sleepers per hour. In railway jargon, a sleeper (in the U.S. called a tie or railroad tie) is the transverse beam that supports the rails and holds them at the correct gauge. The sleeper layer, an attachment to a carrier machine, places and aligns multiple sleepers quickly and accurately during track construction or renovation.

Frangus’ sleeper layer project demanded close coordination between mechanical, electrical, and control systems, all modeled within SOLIDWORKS. “We used [SOLIDWORKS Electrical] to generate the very complex schematics needed for the PLC control system and produce those as 3D models so the assembly team knew exactly what wire went where,” Thompson explains. By modeling both the mechanical and electrical systems, Frangus ensured seamless integration and drastically reduced wiring errors.

“This is an example of the whole suite of SOLIDWORKS products coming into its own,” concludes Thompson. “SOLIDWORKS most definitely gives us a competitive edge. The key thing is we get a product out at the first or second prototype. As a rule, I recommend SOLIDWORKS without hesitation.”

Products:

- SOLIDWORKS Design Premium

- SOLIDWORKS Simulation Professional

- SOLIDWORKS Electrical

- SOLIDWORKS Composer

- SOLIDWORKS eDrawings

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.