How Dry Electrode Technology is Reshaping Battery Production

Energy storage and battery manufacturing company drives collaboration, efficiency, and automation with SOLIDWORKS and the 3DEXPERIENCE platform.

Challenge

Improve robot programming, welding, and forming efficiencies while maximizing resource utilization to boost productivity, shorten delivery times, and increase the competitiveness of pricing.

Solution

Replace Autodesk Inventor tools with 3DEXPERIENCE® SOLIDWORKS® design and the expanded portfolio of data management, collaboration, communication, and manufacturing solutions.

Results

- Automated ECR and ECO processes, reducing engineering response time by 50 percent

- Streamlined drawing review process for new electrode manufacturing equipment

- Enabled rapid sharing and iteration of designs, improving engineering collaboration

- Allowed for easy mass distribution of updates to templates and notes, saving time creating parts and drawings

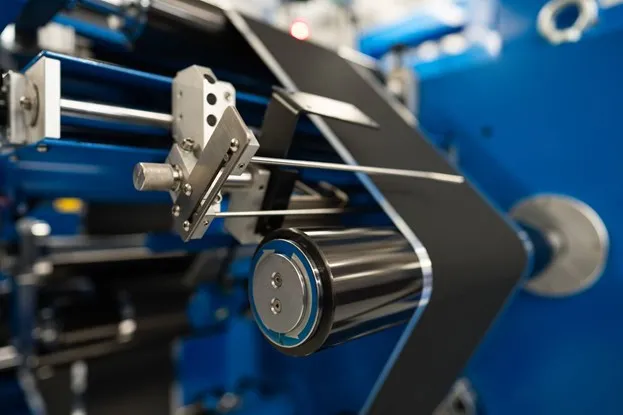

Recognized in Time magazine’s Best Inventions of 2024, AM Batteries has quickly established itself as the leader in dry battery-electrode (DBE) manufacturing technology for lithium-ion batteries used in electric vehicles (EVs), grid-scale storage, and consumer electronics. The company’s innovative Powder to Electrode™ dry coating method sprays dry active material directly onto current collectors, eliminating the toxic solvents and energy-intensive dryers required by traditional wet slurry processes. (A current collector is a thin metal foil, usually aluminum or copper, that carries electrons in and out of a battery’s active material.)

To understand the impact of AM Batteries’ innovation, consider the wider EV battery landscape.

Wet slurry electrode manufacturing requires N-Methylpyrrolidone (NMP) solvent, which is classified as a Substance of Very High Concern by the European Chemicals Agency under the REACH regulation due to its toxicity to human reproduction. Additionally, the United States Environmental Protection Agency has identified NMP as presenting an unreasonable risk of harm to human health under the Toxic Substances Control Act.

A More Sustainable Way to Manufacture

The dry electrode manufacturing process being developed by AM Batteries eliminates the NMP solvent entirely. Its advantages have become clear as Tesla, LG Energy Solution, and other companies have invested in DBE. On the manufacturing side, DBE use enables a safer and more efficient process by reducing energy consumption and eliminating toxic solvents. On the technological side, DBE enables higher energy density and scalability for large-scale battery production.

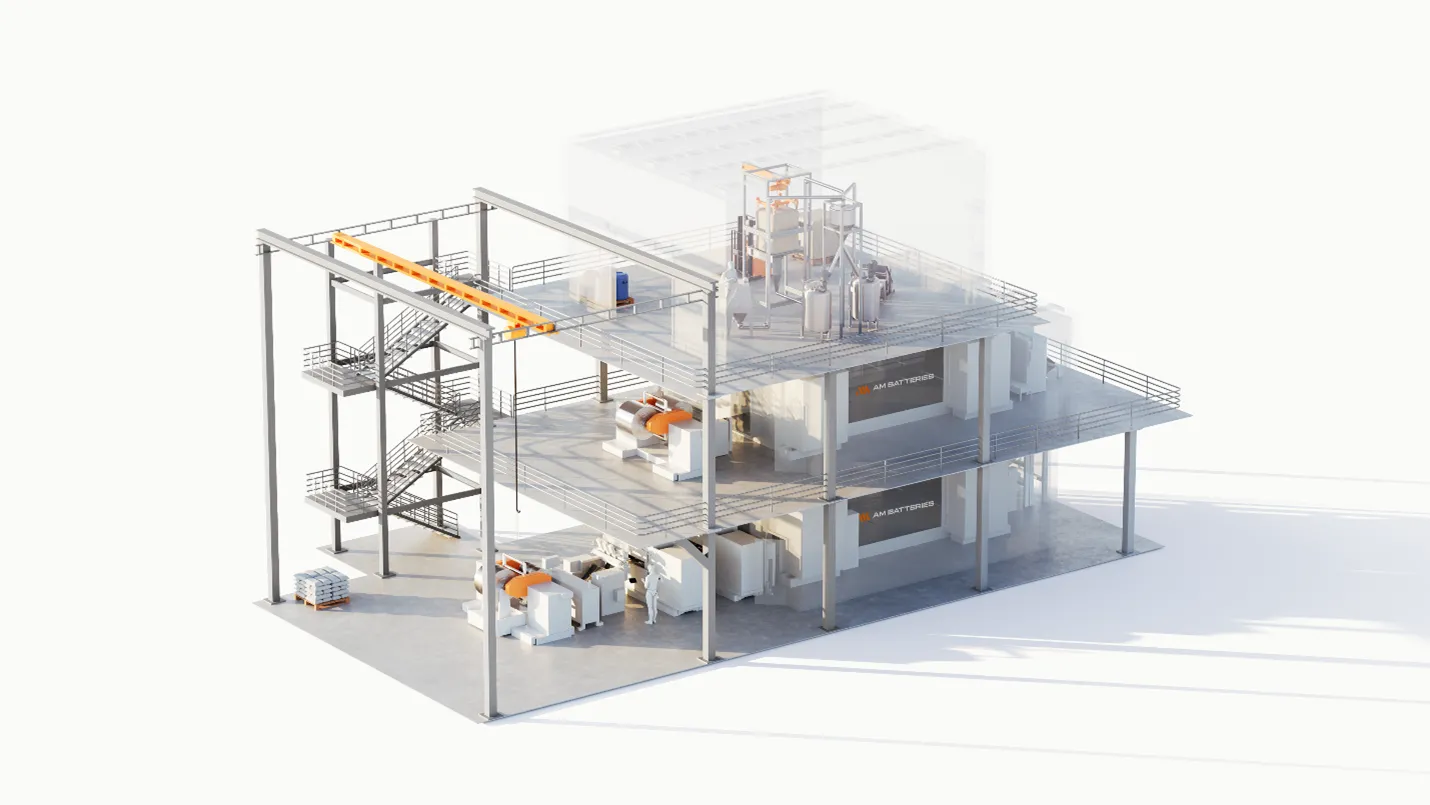

Furthermore, the DBE manufacturing process reduces capital expenditures by up to 40 percent and operating expenses by more than 50 percent. DBE can also shrink the battery factory footprint by five times and cut energy costs by 75 percent. With global demand for batteries skyrocketing, AM Batteries is well-positioned to enable cleaner, faster, and more affordable manufacturing.

Related Resources

Before we moved to data management on the 3DEXPERIENCE platform in the cloud, it was difficult to know the state of a product or what additional metadata might be associated with a part...The really great thing about 3DEXPERIENCE SOLIDWORKS [and the Expanded Portfolio of solutions] is that it’s not just a CAD tool but also a PDM [product data management] tool

Getting the Right Tools for Growth

Founded in 2020 and based in Billerica, Massachusetts, AM Batteries initially relied on Autodesk® Inventor® product development tools, but the limitations became clear by 2024. Mechanical Engineer and CAD Administrator Joel Hauerwas explained that AM Batteries had reached a point where it needed to improve data management, development, and release processes.

With Inventor, revision tracking was cumbersome, release processes were messy, and product data lacked automation. “Product design data was being managed in the Inventor vault, which offered little to no automation,” Hauerwas explains. “Revision tracking was difficult, and the drawings and product release processes were messy. In advance of commercialization of our technology, we needed to improve data management and automate our release processes to support manufacturing.”

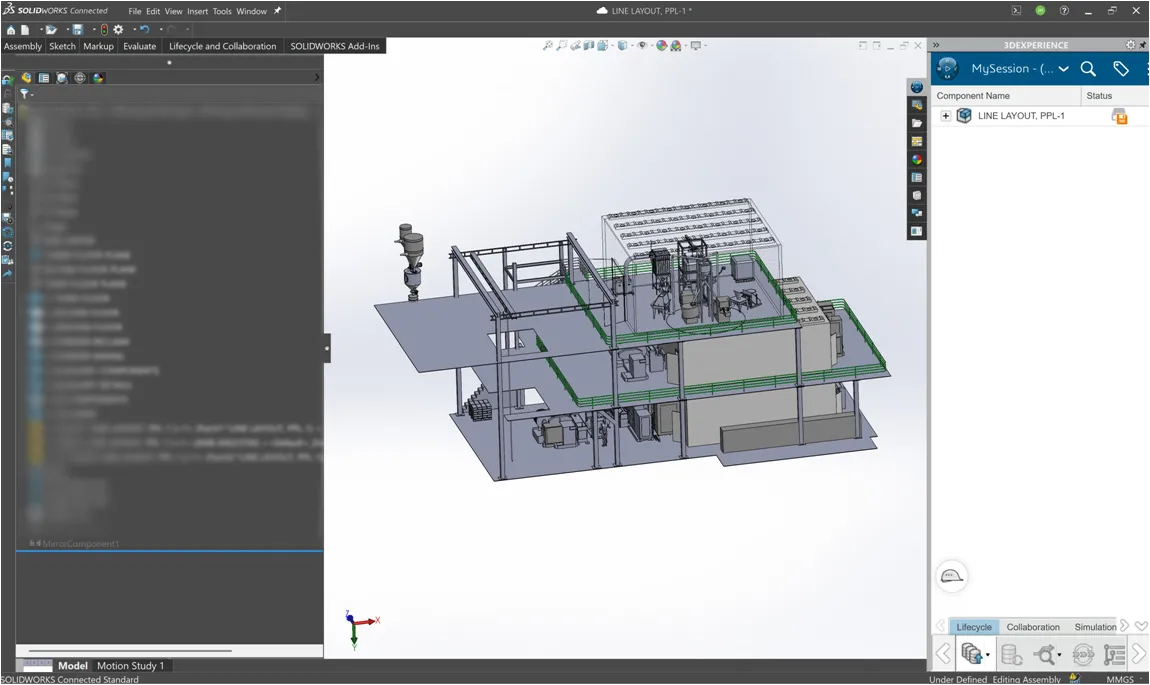

In 2024, AM Batteries replaced Inventor with 3DEXPERIENCE® SOLIDWORKS® and a portfolio of connected applications including Manufacturing Definition Creator and Shop Floor Programmer. AM Batteries migrated 15 GB of data from the Inventor vault to the cloud with the help of SOLIDWORKS reseller GoEngineer.

“Before we moved to data management on the 3DEXPERIENCE platform in the cloud, it was difficult to know the state of a product or what additional metadata might be associated with a part,” Hauerwas recalls. “The really great thing about 3DEXPERIENCE SOLIDWORKS … is that it’s not just a CAD tool but also a PDM tool.”

By centralizing data and processes, AM Batteries can now manage part numbering, drawing release, engineering change orders (ECOs), and safety manuals within the same environment.

Standardization, Automation, and Acceleration

With the move to SOLIDWORKS on the 3DEXPERIENCE platform, AM Batteries cut engineering response times in half by automating engineering change requests and ECO workflows. The team also simplified drawing reviews for new manufacturing equipment and made it easier to share and iterate on designs, which facilitated collaboration among the engineering team.

Standardized templates that update automatically across the organization save additional time. This shift represents more than just a technical upgrade. As Joel Hauerwas explained, “Now templates are automated and standardized, so everyone’s using the same shared templates that are linked to the 3DEXPERIENCE platform.” That change alone has strengthened revision control, improved searchability, and streamlined release processes.

As demand for lithium-ion batteries accelerates, dry-electrode manufacturing is emerging as the industry’s future. Powered by the 3DEXPERIENCE platform and supported by GoEngineer, AM Batteries is not just inventing cleaner, faster, and cheaper batteries, it’s showing the world how to commercialize them.

Products:

- SOLIDWORKS Professional

- Manufacturing Definition Creator

- Shop Floor Programmer

- 3DEXPERIENCE Platform

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.