How GlüxKind Used SOLIDWORKS to Reinvent the Baby Stroller

Baby strollers used to be, well, baby strollers, and definitely not a platform for innovation beyond cosmetic tweaks and cupholders. Then GlüxKind came along.

Challenge

Creating the very first AI baby stroller that is designed not only to carry a child, but to support the daily demands of parenting.

Solution

Start up a new company focused on creating the next-generation product using SOLIDWORKS and 3DEXPERIENCE collaboration tools to bring siloed groups of engineers and designers together to solve a problem together, with help from the SOLIDWORKS Start-up Program.

Results

- Collaborate design information and intent easily between offices

- Manage version control automatically

- Consider weight and strength variables easily

- Develop mechanical and electrical systems into one product

Baby strollers used to be, well, baby strollers, and definitely not a platform for innovation beyond cosmetic tweaks and cupholders. Then GlüxKind came along.

GlüxKind Technologies didn’t set out to disrupt an industry; co-founder and CEO Kevin Huang merely set out to solve a problem. Like many new parents, he struggled with the everyday challenges inherent in child-rearing, including navigating the world with a stroller. That struggle gave birth to Ella: an AI-powered stroller designed not just to carry a child, but to support the daily demands of parenting.

“We make AI-powered baby strollers to make parenting easier,” says Huang. “At the end of the day, we are making co-pilots for parents, to give them an extra set of eyes and hands, whether they're out and about or at home.”

Product Development Challenges

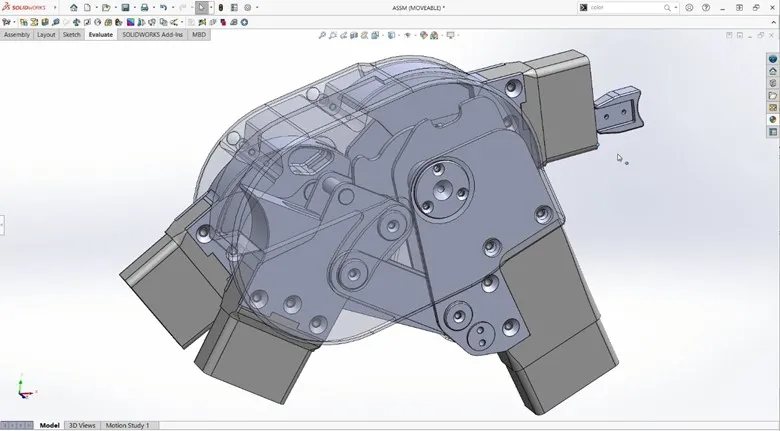

Designing a durable frame that houses multiple motors, sensors, and harnesses without exceeding the weight or footprint of a traditional stroller required numerous iterations and precision. Traditional baby strollers handle a 150-pound load with a simple three-joint system. The GlüxKind Ella meets that same threshold while integrating dozens of components and new movement paths.

The stroller’s design includes push assist, brake assist, autonomous stopping, and features like auto-rocking, white noise playback, and story time. It’s like eight parenting tools in one seamless product.

“Automatic features like “rock my baby” help soothe the child, to sleep for a little bit longer,” adds Huang. “Because when the baby sleeps longer, the parents get more time for each other.”

Behind the scenes, these features demand more than clever programming. They require a mechanically robust, sensor-rich platform with tight tolerances and lightweight construction. And the real engineering feat? It must fold and fit in a trunk.

Related Resources

Our industrial design engineers are based in the UK, and we rely on the 3DEXPERIENCE platform to exchange design files. The UK team focuses on the visual and ergonomic aspects, while we (in Vancouver, British Columbia, Canada) quickly iterate on the mechanical and structural elements. We pass the files back and forth seamlessly throughout the process.

Design, Collaborate, Iterate, Repeat

From concept to production, the team at GlüxKind leveraged Dassault Systèmes SOLIDWORKS® 3D CAD and its simulation tools.

One of the core design challenges was integrating all necessary sensors, along with their wire harnesses and mounting locations, without compromising the stroller’s weight or ability to fold. Despite its advanced technology, the stroller still needed to be light enough for the average adult to lift and compact enough to fit in a car.

This is where SOLIDWORKS Simulation and cloud-based 3DEXPERIENCE® paid off big time.

“Our industrial design engineers are based in the UK, and we rely on the 3DEXPERIENCE platform to exchange design files,” explains Huang. “The UK team focuses on the visual and ergonomic aspects, while we (in Vancouver, British Columbia, Canada) quickly iterate on the mechanical and structural elements. We pass the files back and forth seamlessly throughout the process.”

Those same tools helped streamline the handoff to production, including securely sharing files with overseas partners, maintaining control over design integrity, and speeding up the build cycle. “We share files with some of our production partners in Asia in a controlled manner to get things made quickly,” enthuses Huang. “Having that level of control is fantastic.”

Get There Faster

From idea to product in just three years, GlüxKind has raised the bar for baby gear and for how mechanical engineers approach innovation in human-centric robotics.

“We have some projects in the works for multi-occupancy, and we’re also applying our technology to other things outside the scope of baby products,” concludes Huang. “Because, at the end of the day, there are lots of things that need to move in the pedestrian space.”

For investors, GlüxKind isn’t just a smart stroller inventor, it’s an entry point into a broader mobility platform. It’s a technology stack that’s both autonomous and intuitive with human-centered robotics that require no remote control: With just a touch, it moves. Let go, it stops.

That kind of simplicity takes serious engineering. And GlüxKind has proven they’re more than up to the task.

Products:

- SOLIDWORKS Standard

- SOLIDWORKS Simulation Professional

- Collaborative Designer for SOLIDWORKS

- Collaborative Industry Innovator

- 3DSwymer

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.