ICR Transforms Product Development with SOLIDWORKS and the 3DEXPERIENCE Platform

A technology-enabled provider of specialist repair, inspection, and integrity solutions rockets collaboration and productivity by connecting SOLIDWORKS to the 3DEXPERIENCE platform.

Challenge

Manage and track engineering data which was scattered in offices around the world, and gain better control of intellectual property of designs.

Solution

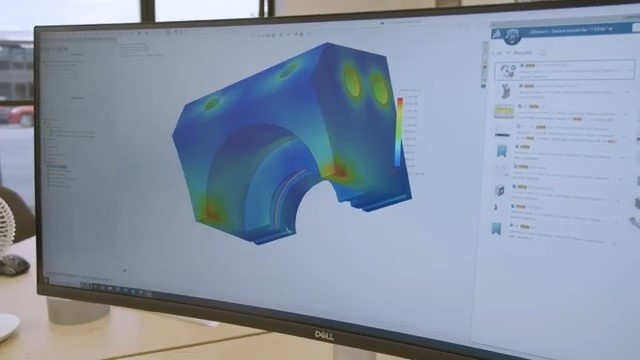

Add 3DEXPERIENCE Works design and collaboration tools, including Product Release Engineer, Collaborative Business Innovator and Collaborative Industry Innovator to efficiently work with people inside and outside their company, including customers, suppliers, and manufacturers. SOLIDWORKS Simulation is used to reduce time testing products.

Results

- Organize all design data which can easily be searched

- Efficiently manage and protect all intellectual property.

- Easily collaborate throughout entire organization on one seamless platform

- Test products virtually, to decrease physical prototyping

ICR Integrity Ltd is a global company that excels in executing complex projects across a variety of sectors, including oil and gas, nuclear cooling systems, renewable energy, utilities, infrastructure, and defense. The company focuses on providing repair, inspection, and integrity services and solutions. Their high-quality offerings not only keep essential assets operational but also save clients both time and money compared with conventional methods.

Three years ago, ICR had to come to terms with its own data management dilemma. Their engineering data was scattered among their offices around the globe and the company had extremely limited access to and control over its own intellectual property (IP). A local reseller introduced ICR to the cloud-based 3DEXPERIENCE platform, which transformed their data management and IP protection capabilities.

“One of the big differentiators for ICR as a business is our speed to market,” says Design Manager Phil Kitchen. “The way we historically stored our content made it very, very difficult to find.” Now organized and searchable under numerous parameters within the 3DEXPERIENCE® platform, design data is easily found and leveraged, which speeds up ICR's entire process. “We implemented the 3DEXPERIENCE platform because it's entirely cloud-based, and it's made it a lot easier for us to protect our IP as well.” Another big benefit of the 3DEXPERIENCE platform’s data management capabilities is its integration with everyday applications such as Word and Excel and, of course, 3D CAD systems like SOLIDWORKS®.

Reducing Physical Testing Time

“We use simulation tools a lot within our company, and a few of us have been trained in SOLIDWORKS Simulation,” says Kitchen. Being proficient in SOLIDWORKS and SOLIDWORKS Simulation while being connected to the cloud-based platform has provided ICR multiple benefits. Kitchen continues, “SOLIDWORKS Simulation reduces the amount of [physical] testing we need to do on our products.”

Related Resources

We implemented the 3DEXPERIENCE platform because it's entirely cloud-based, and it's made it a lot easier for us to protect our IP as well.

Collaboration Builds Community

ICR also leverages access to 3DEXPERIENCE communities around the world that use both cloud solutions and SOLIDWORKS.

“The 3DEXPERIENCE platform has certainly allowed us to speed up getting our solutions to market,” reports Kitchen. “It has increased our productivity in terms of design, and it has increased our productivity in terms of manufacturing because we can share our designs with external manufacturers directly from the platform.”

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.