J.A.M.E.S Advances the Evolution of 3D Printed Electronics with Community-Driven Online Platform

By leveraging SOLIDWORKS and cloud-based 3DEXPERIENCE Works Simulation, German company accelerates the development and innovation of 3D-printed electronics.

Challenge

Harness community-driven innovation to advance the development of 3D-printed electronics and speeds up the production of professional multilayer PCB prototypes, experimental electronic circuits, antennas, and more.

Solution

Adding 3DEXPERIENCE® Works collaboration, data management and collaboration solutions, including Collaborative Designer for SOLIDWORKS®, Collaborative Industry Innovator, Collaborative Business Innovator to connect and easily access all design data on the cloud.

Results

- Quicker revisions and more creativity in board designs

- Easily manage data and all product revisions

- Easier scalability as company grows

- Allowing community-driven collaboration for new designs

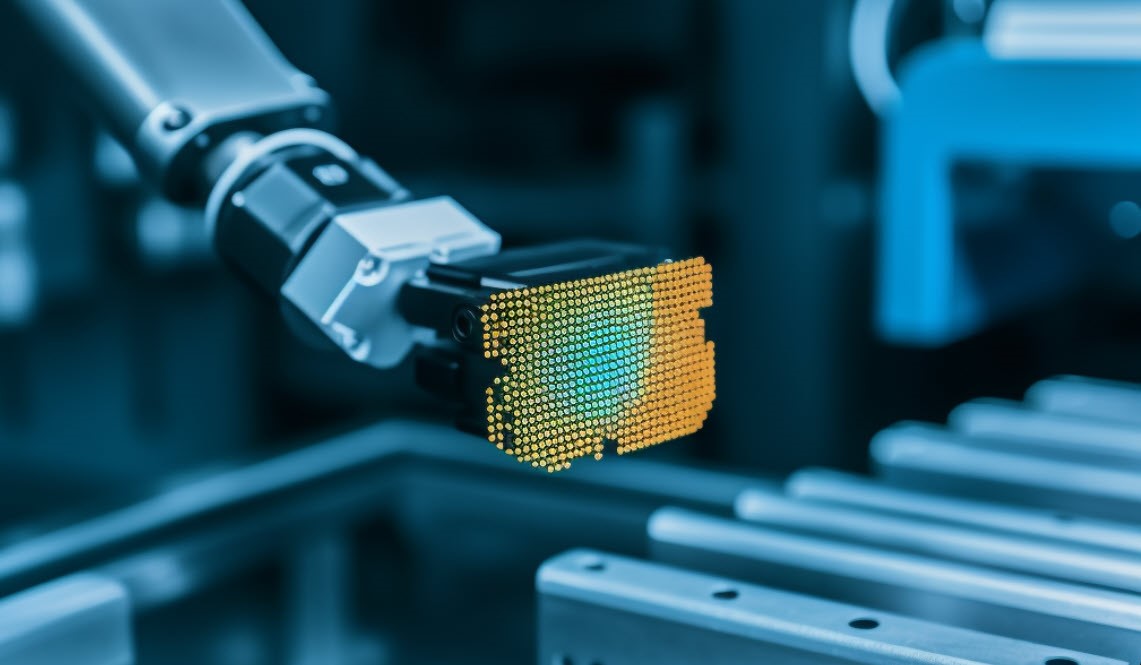

J.A.M.E.S GmbH aims to advance the development—and ultimately production—of additively manufactured electronics (AME) systems and components. The company has established a platform focused on harnessing community-driven innovation to advance the development of 3D-printed electronics while offering in-house electronics printing, connection to partner networks, and AME project consulting.

The story of J.A.M.E.S (Jetted Additively Manufactured Electronics Sources) started in 2016 at Hensoldt AG, a German armaments manufacturer specializing in radar systems and military electronics. Hensoldt initially leased a DragonFly 2020 Pro from 3D printer manufacturer Nano Dimension and eventually bought the machine for electronics development in 2019.

The DragonFly comes with a precise inkjet deposition system, allowing for printing high-resolution trace and space systems. It can construct a full range of multilayer PCB features, including specialized interconnections. This technology also supports in-house design and speeds up the production of professional multilayer PCB prototypes, experimental electronic circuits, antennas, and more. As a result, it facilitates quicker revisions and fosters greater creativity in board designs.

Solving AME Challenges within a Community

Hensoldt invested heavily in this promising printer technology and conducted many experiments but soon realized the technology was still emerging. Because of its vast potential, the company formed a joint venture with printer manufacturer Nano Dimension to accelerate technology development.

Founded in 2021 in Taufkirchen, Germany, J.A.M.E.S aims to revolutionize the electronics industry through advanced 3D printing technology. It also seeks to accelerate development and problem-solving by building an online, community-driven platform for collaboration among electronics designers and manufacturers.

Related Resources

Digitally Validating Electronics Designs

“The challenge of this technology is that traditional electronics have turned to 3D,” says J.A.M.E.S Head of Engineering Rolf Baltes. “Old-fashioned electronics design works with layer-based 2.5D. But [SIMULIA’s] CST [Studio] is inherently a 3D tool already and is familiar with electronics.”

Baltes continues, “The convergence of both worlds is the core function of CST [Studio], being developed specifically for this purpose. It also incorporates functions to simulate everything in the HF (high frequency) and LF (low frequency) ranges. Being able to validate our prototypes virtually is a much-appreciated benefit.”

Getting More Power from the Cloud

Dassault Systèmes SOLIDWORKS is at the heart of 3D design at J.A.M.E.S, “SOLIDWORKS is used in all stages of the design,” says Technical Design Engineer Pascal Fischer. “The most important feature of SOLIDWORKS is its ability to parametrize everything and that DXF files can be added to the sketches.”

Baltes continues, “After we had gathered some satisfactory experience with SOLIDWORKS and CST [Studio], our next step was to convert offline operations to go online with the 3DEXPERIENCE platform. This would achieve a higher scalability, giving us a basis for future growth.”

In addition, the 3DEXPERIENCE platform allows J.A.M.E.S to run simulations in the cloud, all from a basic office laptop. Baltes concludes, “And our management has the advantage of being able to see project progress online.”

Learn More About SOLIDWORKS and 3DEXPERIENCE Works

Have questions about SOLIDWORKS Solutions?

SOLIDWORKS solutions enable you and your team to quickly transform new ideas into great products.